Wave Soldering Oven

ND250 Wave Soldering Oven

Specification

| Product name | ND250 Wave Soldering Oven |

| Model | ND250 |

| Wave | Duble Wave |

| PCB Width | Max250mm |

| Tin tank capacity | 200KG |

| Preheating | Length: 800mm(2 section) |

| Wave Height | 12mm |

| PCB Conveyor Height | 750±20mm |

| Preheating Zones | Room temperature-180℃ |

| Solder temperature | Room Temperature-300℃ |

| Machine size | 1800*1200*1500mm |

| Packing size | 2600*1200*1600mm |

Details

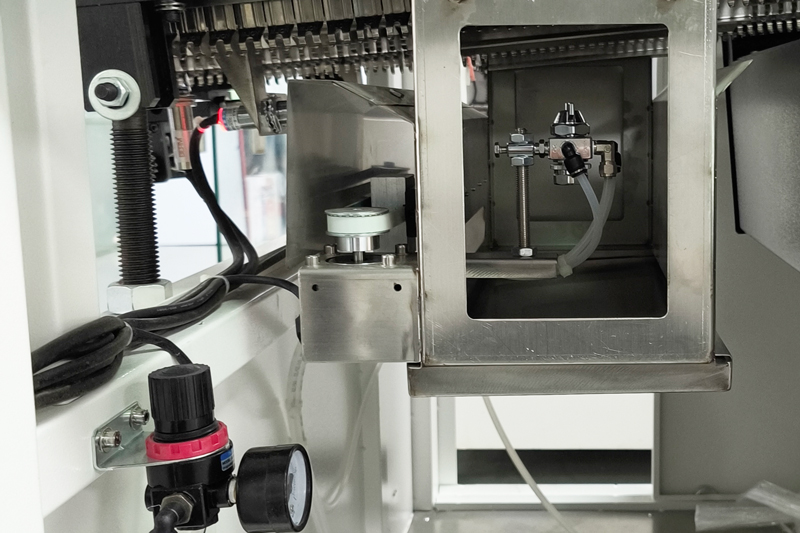

Control Method: Touch Screen

Heating Method: Hot Wind

Cooling method: Axial fan cooling

Transfer Direction: Left→Right

Temperature Control: PID+SSR

Machine Control: Mitsubishi PLC+ Touch Screen

Flux tank capacity: Max 5.2L

Spray Method: Step Motor+ST-6

The layout of the overall mechanism is reasonably designed, simple to operate and easy to maintain.

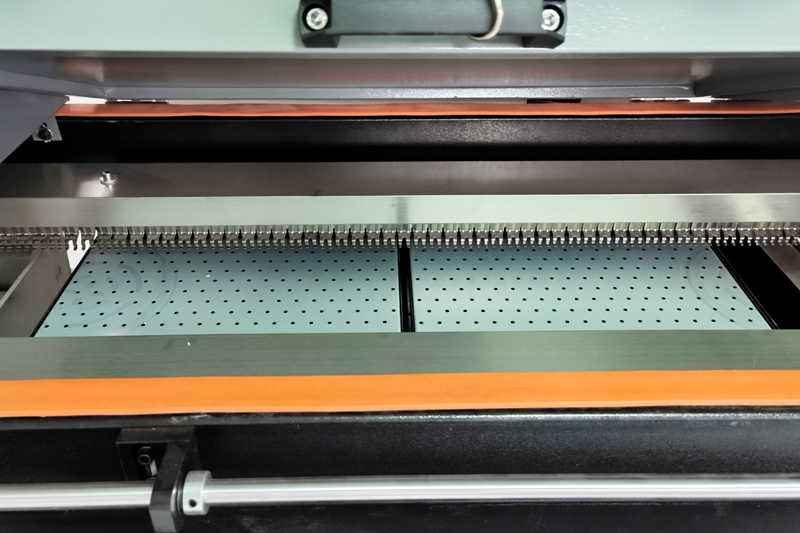

The first wave and the second wave both adopt stepless electronic frequency conversion technology, independent control, suitable for various types of PCB board welding.

The preheating system and welding system both adopt PID control mode, with high precision of temperature control.

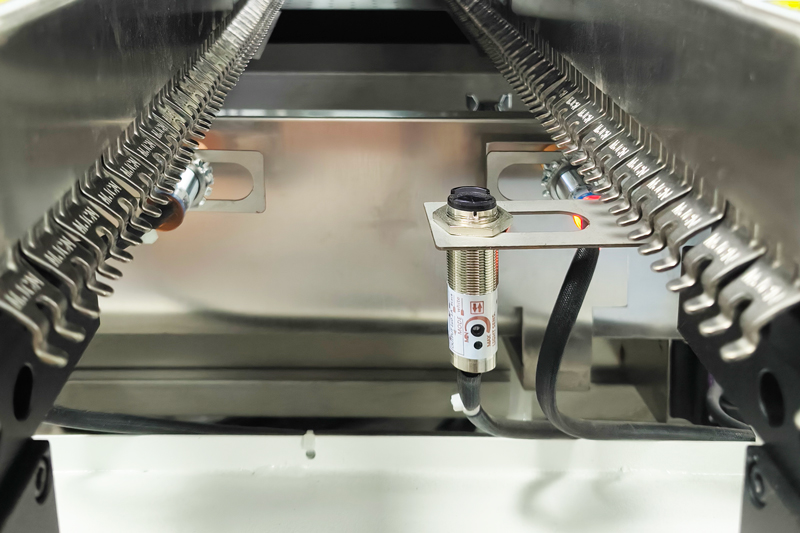

The area of flux spraying is automatically controlled by the size of PCB without manual adjustment of sensor position.

Transportation system adopts stepless electronic speed control system with closed-loop control and stable speed.

Wave soldering oven has over-temperature sound light alarm, emergency braking system, all motors have overload protection system.

It can be turned on fully automatically according to the date and time set by the user.

Quality Control

We have QC person stay on the production lines do to the inspection.

All products must have been inspected before delivery.

We do inline inspection and final inspection.

1. All raw material checked once it arrive our factory.

2. All pieces and logo and all details checked during production.

3. All packing details checked during production.

4. All production quality and packing checked on final inspection after finished.

Provide one-stop SMT assembly production line

Related products

FAQ

Q1. Are you a manufacturer, trading company or a third party?

A. We are a professional Wave Soldering Oven manufacturer, and we have builded up our company since 2010.

with 15 years professional experience, we can provide you suitable SMT solutions.

Assessed by third party, national patents and CE, ISO for our equipments, we do very well on Wave Soldering Oven.

Q2. If l don't know which reflow oven can meet my needs, will you help me?

A: Just take it easy, you just need to provide us your requirements, then we can suggest the most suitable Wave Soldering Oven to you.

We will provide you our E-catalogue for your reference, tell us what you like, we will provide professional suggest.

Q3. How your quality guarantee?

A: We have 100% quality guarantee to customers.

We will be responsible for any quality problem.

About us

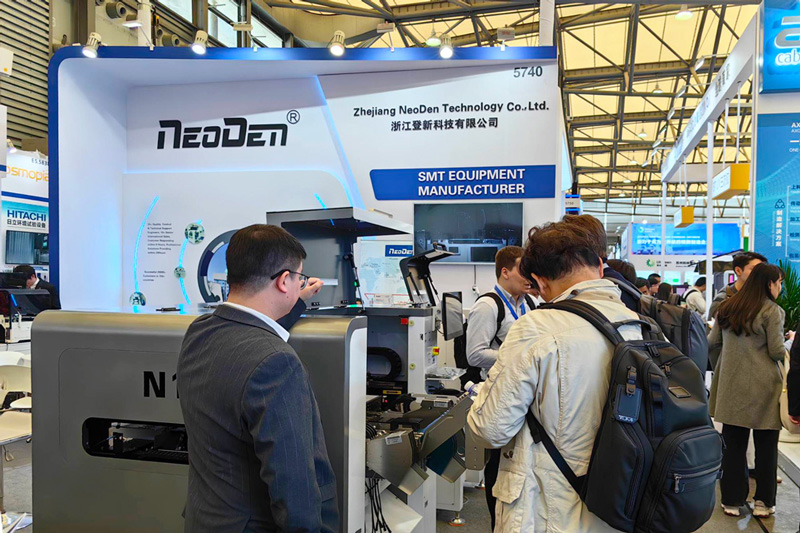

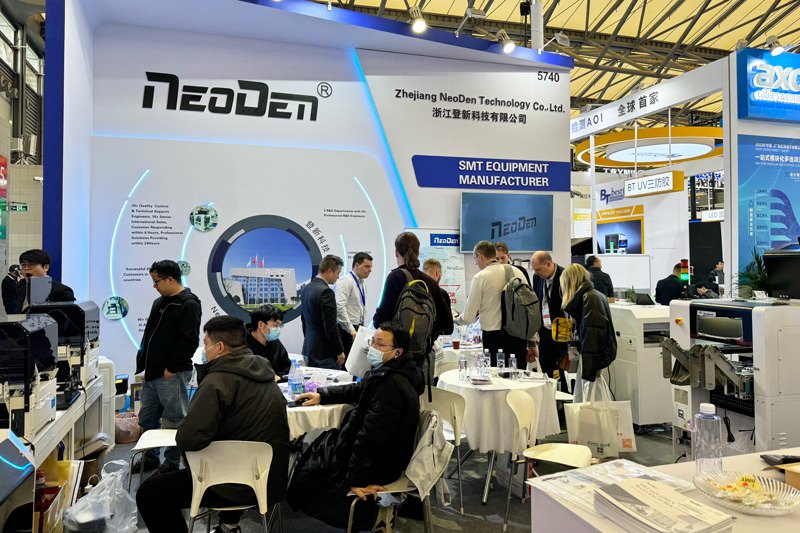

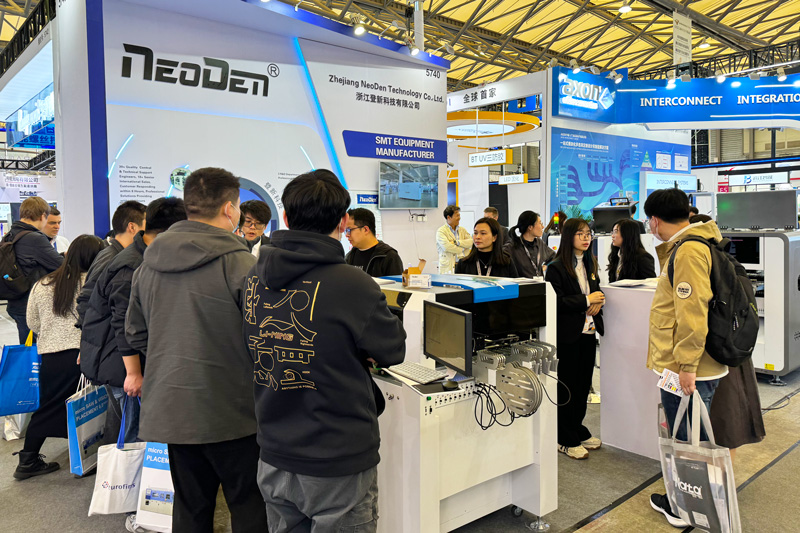

Exhibition

Certification

Factory

Zhejiang NeoDen Technology Co., Ltd. has been manufacturing and exporting various small pick and place machines since 2010. Taking advantage of our own rich experienced R&D, well trained production, NeoDen wins great reputation from the world wide customers.

In our global Ecosystem, we collaborate with our best partners to deliver a more closing sales service, high professional and efficient technical support.

We believe that great people and partners make NeoDen a great company and that our commitment to Innovation, Diversity and Sustainability ensures that SMT automation is accessible to every hobbyist everywhere.

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.