Surface Mount Technology SMT Machine

Surface Mount Technology SMT Machine

Features

1. Equips with 2 mark cameras to ensure that all picking positions can be photographed;

2. Applicale for the maximum PCB width at 300mm,meets most of the PCB sizes.

3. Equips with the magnetic scale technology what used commonly in the well-known brands, realizing true closed-loop control, long-term assurance of stable placement accuracy as initial & new conditions, easy to calibrate accuracy without suppliers' engineers.

Specification

| Product Name | Surface Mount Technology SMT Machine |

| Number of Heads | 6 |

| Number of Tape reel Feeders | 53(Yamaha Electric/Pneumatic) |

| Number of IC Tray | 20 |

| Placement Area | 460mm*300mm |

| MAX Mounting Height | 16mm |

| PCB Fiducial Recognition | High Precision Mark Camera |

| Component Recognition | High Resolution Flying Vision Camera System |

| XY Motion feedback control |

Closed loop control system |

| XY Drive motor | PanasonicA6 400W |

| Repeat Position Accuracy | ±0.01mm |

| Maximum Mounting Speed | 14000CPH |

| Average Mounting Speed |

9000CPH |

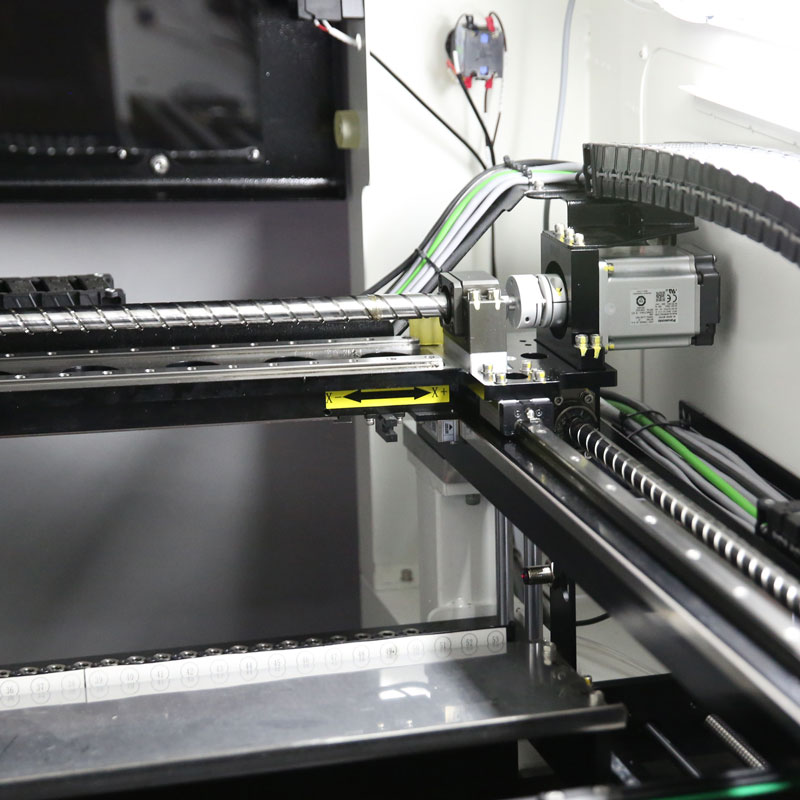

| X-axis-Drive Type | WON Linear Guide / TBI Grinding screw C5 - 1632 |

| Y-axis-Drive Type | WON Linear Guide / TBI Grinding screw C5 - 1632 |

| Compressed Air | >0.6Mpa |

| Input Power | 220V/50HZ(110V/60HZ Alternative) |

| Machine Weight | 500KG |

| Machine Dimension | L1220mm*W800mm*H1350mm |

Product Detail

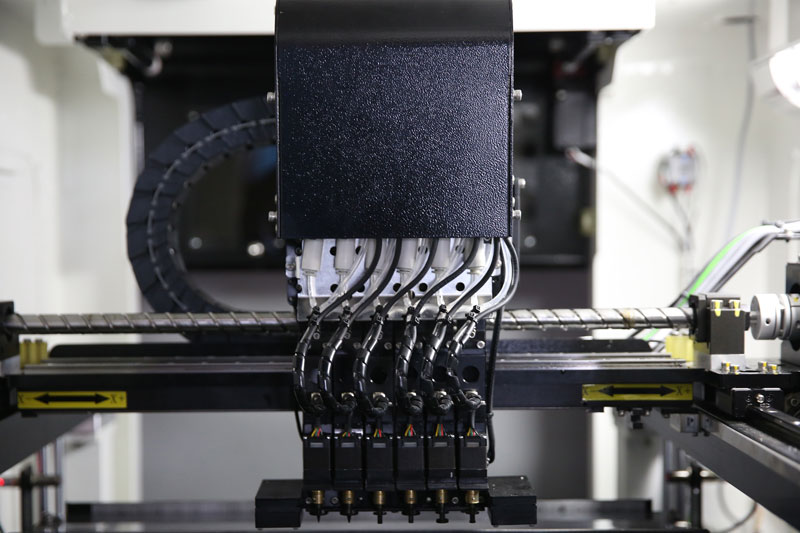

6 Placement Heads

Rotation: +/-180 (360)

Up and down separately, easy to pick up

53 Slots Tape Reel Feeders

Supports electric feeder & pneumatic feeder

high efficiency with flexible, worthiest space

Flying Cameras

Uses imported CMOS sensor

Ensure the stable and durable effects

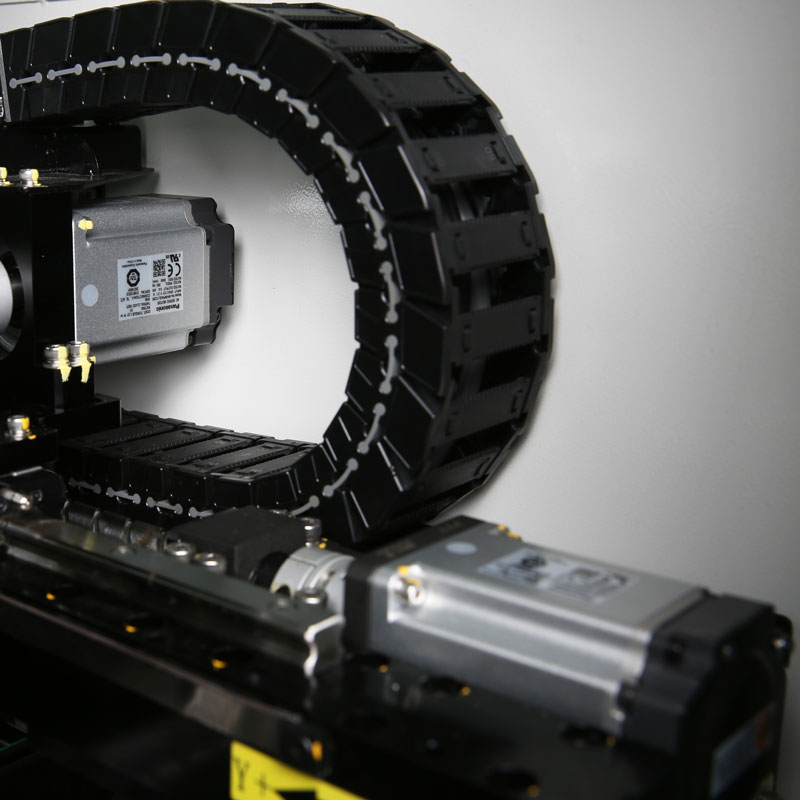

Drive Motor

Panosonic 400W servo motor

Ensure better torque and acceleration

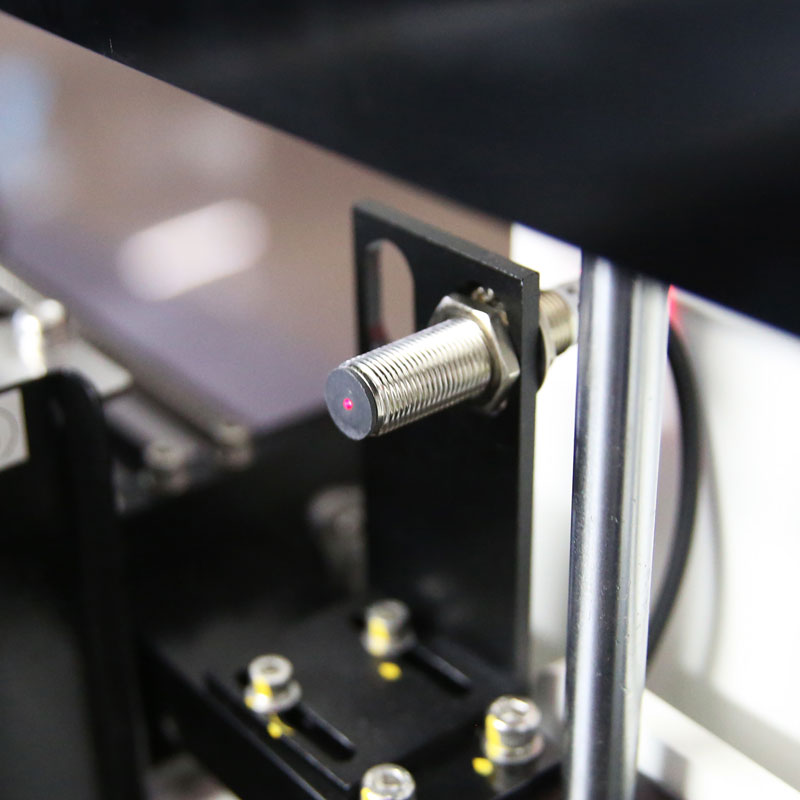

Patent Sensors

Avoid head bumps and abnormalities

by misoperation

C5 precision ground screw

Less wear and aging

Stable and durable precision

Our Service

1 .More Professional service in PNP machine field

2. Better manufacture ability

3. Various payment term to choose: T/T, Western Union, L/C, Paypal

4. High quality/Safe material/Competitive price

5. Small order available

6. Quickly response

7. More safe and fast transport

If you need, please feel free to contact us for more information.

About us

Factory

Zhejiang NeoDen Technology Co., Ltd. has been manufacturing and exporting various small pick and place machines since 2010. Taking advantage of our own rich experienced R&D, well trained production, NeoDen wins great reputation from the world wide customers.

with global presence in over 130 countries, the excellent performance, high accuracy and reliability of NeoDen PNP machines make them perfect for R&D, professional prototyping and small to medium batch production. We provide professional solution of one stop SMT equipment.

Certification

Exhibition

FAQ

Q1. What is your terms of delivery?

A: We accept EXW, FOB, CFR, CIF, etc.

You can choose the one which is the most convenient or cost effective for you.

Q2. How many square meters of your factory?

A: More than 8,000 square meter.

Q3. Do you have after-sale service?

A: Yes, good after-sale service, handling the customer complaint and solve problem for customers.

Q4. Can we visit your factory before place the order?

A: Yes,very welcome that must be nice to set up good relationship for business.

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.