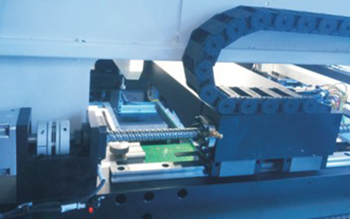

Solder Paster Printer

Solder Paster Printer

Specification

| Product name | Solder Paster Printer |

| Maximum board size(X x Y) | 450mm x 350mm |

| Minimum board size(X x Y) | 50mm x 50mm |

| PCB thickness | 0.4mm~6mm |

| Warpage | ≤1% Diagonal |

| Maximum board weight | 3Kg |

| Board margin gap | Configuration to 3mm |

| Maximum bottom gap | 20mm |

| Transfer speed | 1500mm/s(Max) |

| Transfer height from the ground | 900±40mm |

| Transfer orbit direction | L-R,R-L,L-L,R-R |

| Machine weight | Appro.1000Kg |

Feature

Standard Configuration

1. HTGD Special PCB thickness adaptive system

The platform height is automatically calibrated according to PCB thickness setting, which is intelligent, fast, simple and reliable in structure.

2. Printing axis servo drive

The scraper Y axis adopts servo motor drive through screw drive,to improve accuracy grade,operational stability and extend the service life,to provide customers with a good printing control platform.

Options Configuration

1. Automatic dispensing function

According to different printing process requirements, after printing, the PCB can be carry out accurate dispensing, tin dispensing,ine drawing, filling and other functional operations.

2. Squeegee pressure close-loop feedback control

Built in precise digital pressure sensor control system, through the squeegee pressure feedback system.

It can accurately display the original pressure value of squeegee, intelligently adjust the depth of the blade pressing down ensure the pressure value is constant during the printing process and obtain the highest process control, achieve perfect printing of high density and fine spacing devices.

Provide one-stop SMT assembly production line

Related products

About us

Factory

3 different R&D teams with total 25+ professional R&D engineers, to ensure the better and more advanced developments and new innovation.

Skilled and professional english support&service engineers, to ensure the prompt response within 8 hours, solution provides within 24 hours.

The unique one among all of the Chinese manufacturers who registered and approved CE by TUV NORD.

Certification

Exhibition

FAQ

Q1: What’s your tem of the delivery?

A: Our ordinary delivery term is FOB Shanghai. We also accept EXW, CFR, CIF, DDP, DDU etc.

We’ll offer you the shipping charges and you can choose the one which is the most convenient and effective for you.

Q2: What's your products?

A. SMT machine, AOI, reflow oven, PCB loader, stencil printer.

Q3: What about the lead time for mass production?

A: Honestly, it depends on the order quantity and the season you place the order.

Alway 15-30 days based on general order.

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.