Solder Paste Stencil Machine

Solder Paste Stencil Machine

Specification

| Product name | Solder Paste Stencil Machine |

| Maximum board size(X x Y) | 450mm x 350mm |

| Minimum board size(X x Y) | 50mm x 50mm |

| PCB thickness | 0.4mm~6mm |

| Warpage | ≤1% Diagonal |

| Maximum board weight | 3Kg |

| Board margin gap | Configuration to 3mm |

| Maximum bottom gap | 20mm |

| Transfer speed | 1500mm/s(Max) |

| Transfer height from the ground | 900±40mm |

| Transfer orbit direction | L-R,R-L,L-L,R-R |

| Machine weight | Appro.1000Kg |

Feature

Standard Configuration

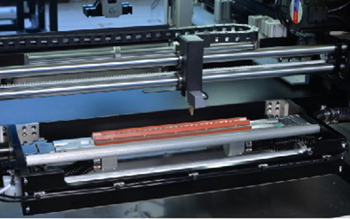

1. Intelligent squeegee system

Intelligent programmable setting, two independent direct motors driven squeegee, built-in precise pressure control system.

2. High efficiency and high adaptability stencil cleaning system

The new wiping system ensures full contact with the stencil.

Three cleaning methods of dry, wet and vacuum, and free combination can be selected.

Soft wear-resistant rubber wiping plate, thorough cleaning, convenient disassembly, and universal length of wiping paper.

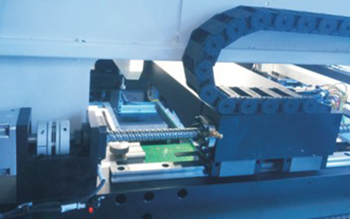

3. Printing axis servo drive

The scraper Y axis adopts servo motor drive through screw drive,to improve accuracy grade, operational stability and extend the service life, to provide customers with a good printing control platform.

Options Configuration

1. Automatic Solder Paste filling function

Automatically add solder paste at fixed time and fixed point to ensure the quality of solder paste and the amount of solder paste in the steel mesh.

In order to ensure that customers can carry out quality stability and long-term continuous printing, improve productivity.

2. Detection function on Stencil

By compensating the light source above the steel stencil, CCD is used to check the mesh in real time, so as to quickly detect and judge whether the mesh is blocked after cleaning, and carry out automatic cleaning, which is a supplement to the 2D detection of PCB.

Our Service

We are in a good position not only to supply you high quality pnp machine, but also the excellent after sales service.

Well-trained engineers will offer you any technical support.

10 engineers powerful after-sales service team can respond customers queries and enquiries within 8 hours.

Professional solutions can be offered within 24 hours both workday and holidays.

Provide one-stop SMT assembly production line

Related products

About us

Factory

Zhejiang NeoDen Technology Co., LTD., founded in 2010, is a professional manufacturer specialized in SMT pick and place machine, reflow oven, stencil printing machine, SMT production line and other SMT Products. In this decade, we independently developed NeoDen4, NeoDen IN6, NeoDen K1830, NeoDen FP2636 and other SMT products, which sold well all over the world.

In our global Ecosystem, we collaborate with our best partner to deliver a more closing sales service, high professional and efficient technical support.

① NeoDen products: Smart series PNP machine, NeoDen K1830, NeoDen4, NeoDen3V, NeoDen7, NeoDen6, TM220A, TM240A, TM245P, reflow oven IN6, IN12, Solder paste printer FP2636, PM3040

② Listed with CE and got 50+ patents

Certification

Exhibition

FAQ

Q1: When can I get the price?

A: Usually we quote within 8 hours after we get your inquiry.

Q2: What’s is your shipping service?

A: We can provide services for vessel booking, goods consolidation, customs declaration, shipping documents preparation and delivery bulk at the shipping port.

Q3: This is the first time I use this kind of machine, is it easy to operate?

A: Yes. There are English manual and guide video that show you how to use machine.

If there is any doubt in the process of operating the machine, please feel free contact us.

We also provide overseas on-site service.

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.