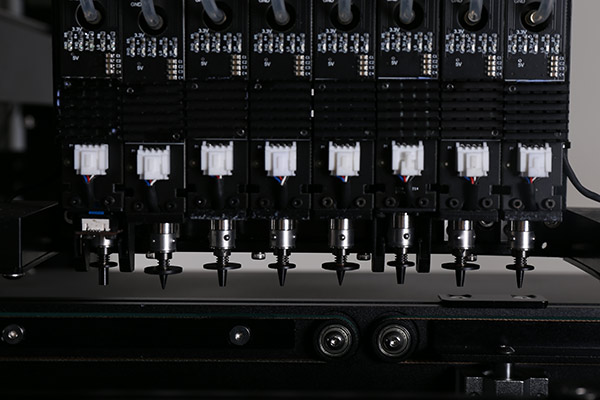

SMT pick and place machine Neoden K1830

| Model | NeoDen-K1830 |

| Nozzle head qty | 8 |

| Reel tape feeder qty max. | 66 |

| Tray feeder qty | 10 |

| PCB size max. | 760*300mm (under single phase) |

| Component available size | 0201 (electric feeder), 0402-1210 |

| IC available | QFP, SSOP, QFN, BGA |

| Placement accuracy | 0.01mm |

| Component available height max. | 18mm |

| Air supply | >0.6MPa |

| Power | 500W |

| Voltage | 220/ 110V |

| Speed max. | 16,000cph |

| Component recognition | Flying vision |

| PCB recognition | High precision mark camera |

| PCB transfer direction | Left→right |

Accuracy:

Closed loop control system can realize a high precision feedback system.

Easy operation:

Realize setting batch feeders’ pick-up position at the same time Realize setting batch feeder’s pick-up height at the same time

Double mark cameras can reach each feeder’s position

Support both electric feeder and pneumatic feeder, feeder selection more flexibly

Advantages compared with N7:

More feeder qty; Internal rails more stable; Higher placement precision

Mechanical structure more reasonable

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.