SMT Surface Mounting Machine

SMT Surface Mounting Machine

Features

1. Equips Panosonic 400W servo motor, to ensure better torque and acceleration for achiving stable and durable placement.

2. Supports both electric feeder and pneumatic feeder at max 53 slots tape reel feeders with machine width 800mm only, to ensure the high efficiency with flexible & worthiest space.

3. Equips with 2 mark cameras to ensure that all picking positions can be photographed.

4. Applicale for the maximum PCB width at 300mm, meets most of the PCB sizes.

Specification

| Product Name | SMT Surface Mounting Machine |

| Number of Heads | 6 |

| Number of Tape reel Feeders | 53(Yamaha Electric/Pneumatic) |

| Number of IC Tray | 20 |

| Placement Area | 460mm*300mm |

| MAX Mounting Height | 16mm |

| PCB Fiducial Recognition | High Precision Mark Camera |

| Component Recognition | High Resolution Flying Vision Camera System |

| XY Motion feedback control | Closed loop control system |

| XY Drive motor | PanasonicA6 400W |

| Repeat Position Accuracy | ±0.01mm |

| Maximum Mounting Speed | 14000CPH |

| Average Mounting Speed |

9000CPH |

| X-axis-Drive Type | WON Linear Guide / TBI Grinding screw C5 - 1632 |

| Y-axis-Drive Type | WON Linear Guide / TBI Grinding screw C5 - 1632 |

| Compressed Air | >0.6Mpa |

| Input Power | 220V/50HZ(110V/60HZ Alternative) |

| Machine Weight | 500KG |

| Machine Dimension | L1220mm*W800mm*H1350mm |

Product Detail

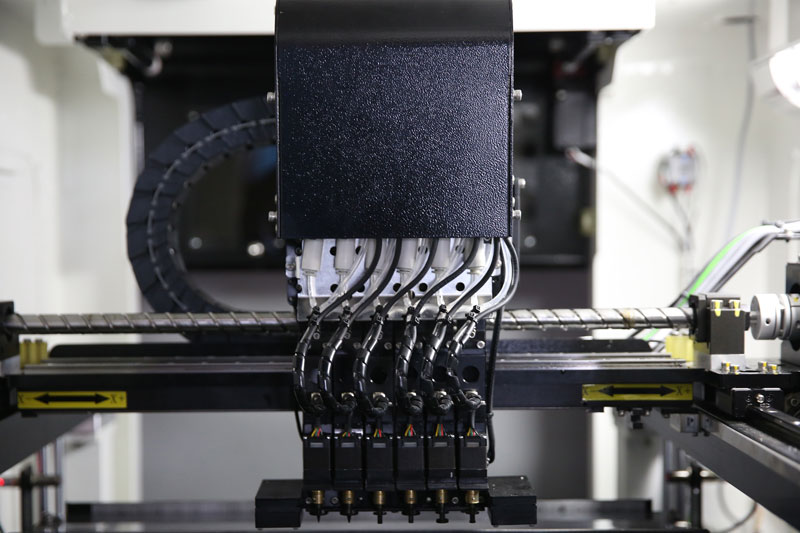

6 Placement Heads

Rotation: +/-180 (360)

Up and down separately, easy to pick up

53 Slots Tape Reel Feeders

Supports electric feeder & pneumatic feeder

high efficiency with flexible, worthiest space

Flying Cameras

Uses imported CMOS sensor

Ensure the stable and durable effects

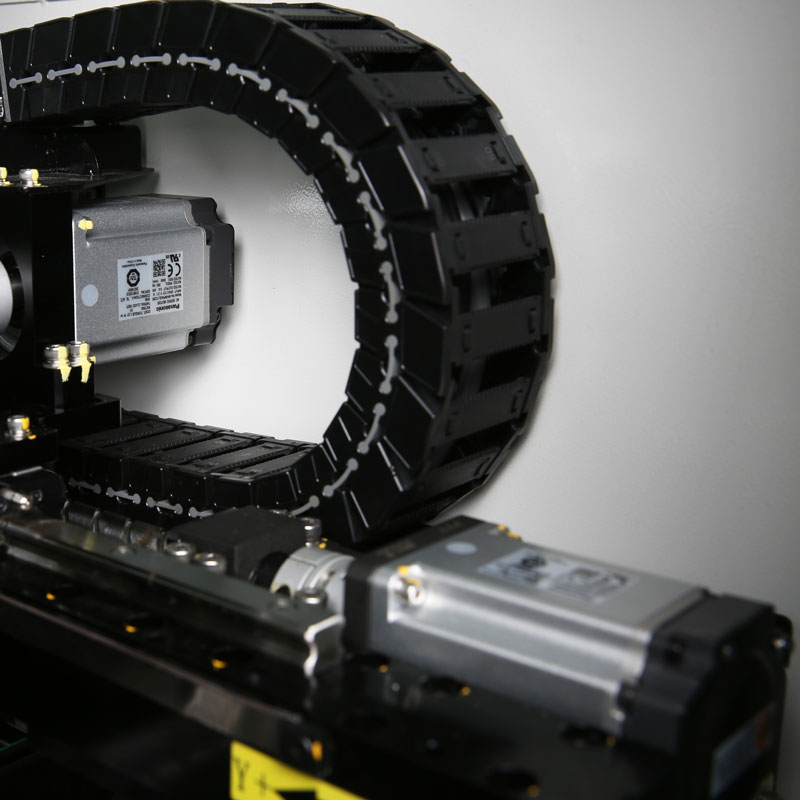

Drive Motor

Panosonic 400W servo motor

Ensure better torque and acceleration

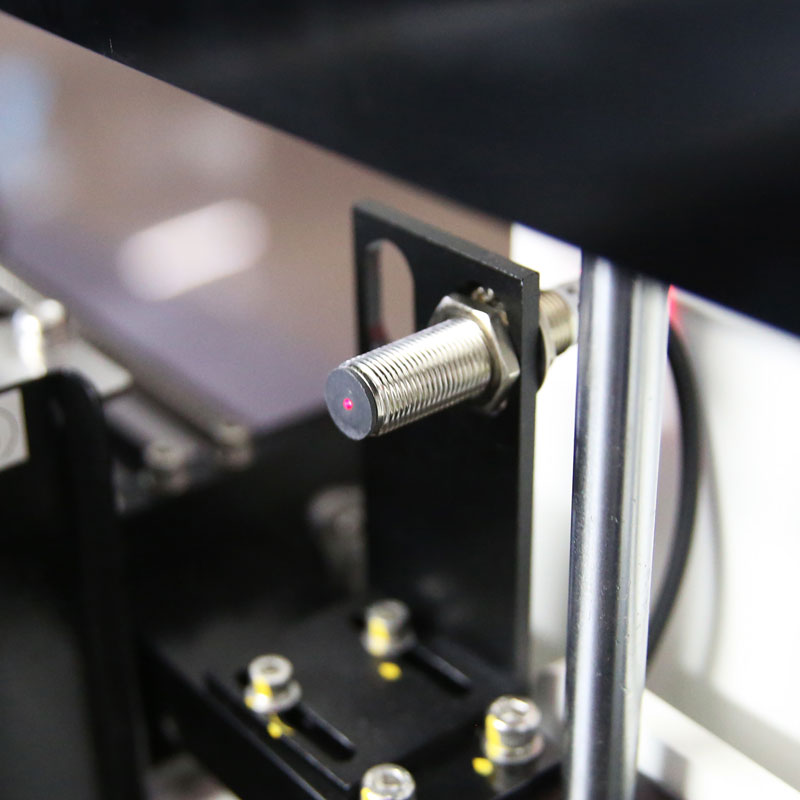

Patent Sensors

Avoid head bumps and abnormalities

by misoperation

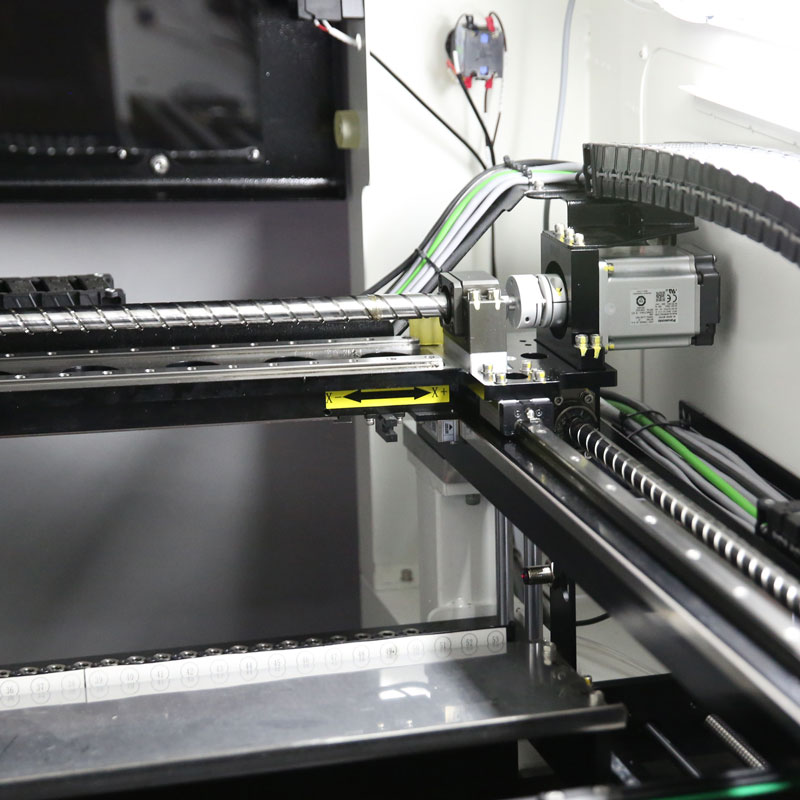

C5 precision ground screw

Less wear and aging

Stable and durable precision

If you need, please feel free to contact us for more information.

About us

Factory

Certification

Exhibition

FAQ

Q1: Which payment form you can accept?

A: T/T, Western Union, PayPal etc.

We accept any convenient and swift payment term.

Q2: What’s is your shipping service?

A: We can provide services for vessel booking, goods consolidation, customs declaration, shipping documents preparation and delivery bulk at the shipping port.

Q3: When can I get the quotation?

A: We usually quote within 8 hours after we get your inquiry.

If you are very urgent to get the price, please tell us so that we will regard your inquiry priority.

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.