SMT Surface Mount Placement Machine

SMT Surface Mount Placement Machine

Features

Equips with the magnetic scale technology what used commonly in the well-known brands, realizing true closed-loop control, long-term assurance of stable placement accuracy as initial & new conditions, easy to calibrate accuracy without suppliers' engineers.

The self-developed flying camera recognition system uses imported CMOS sensor, 5 million-level industrial high-definition lens and 289 LEDs ring shadowless light sources,to ensure the stable and durable effects.

Specification

| Product Name | SMT Surface Mount Placement Machine |

| Number of Heads | 6 |

| Number of Tape reel Feeders | 53(Yamaha Electric/Pneumatic) |

| Number of IC Tray | 20 |

| Placement Area | 460mm*300mm |

| MAX Mounting Height | 16mm |

| PCB Fiducial Recognition | High Precision Mark Camera |

| Component Recognition | High Resolution Flying Vision Camera System |

| XY Motion feedback control | Closed loop control system |

| XY Drive motor | PanasonicA6 400W |

| Repeat Position Accuracy | ±0.01mm |

| Maximum Mounting Speed | 14000CPH |

| Average Mounting Speed |

9000CPH |

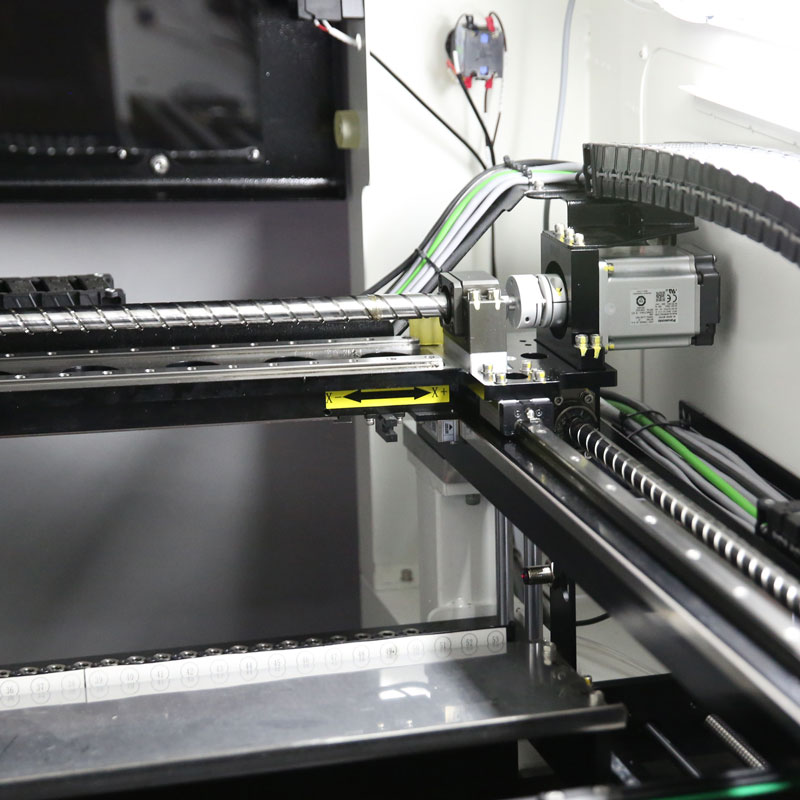

| X-axis-Drive Type | WON Linear Guide / TBI Grinding screw C5 - 1632 |

| Y-axis-Drive Type | WON Linear Guide / TBI Grinding screw C5 - 1632 |

| Compressed Air | >0.6Mpa |

| Input Power | 220V/50HZ(110V/60HZ Alternative) |

| Machine Weight | 500KG |

| Machine Dimension | L1220mm*W800mm*H1350mm |

Product Detail

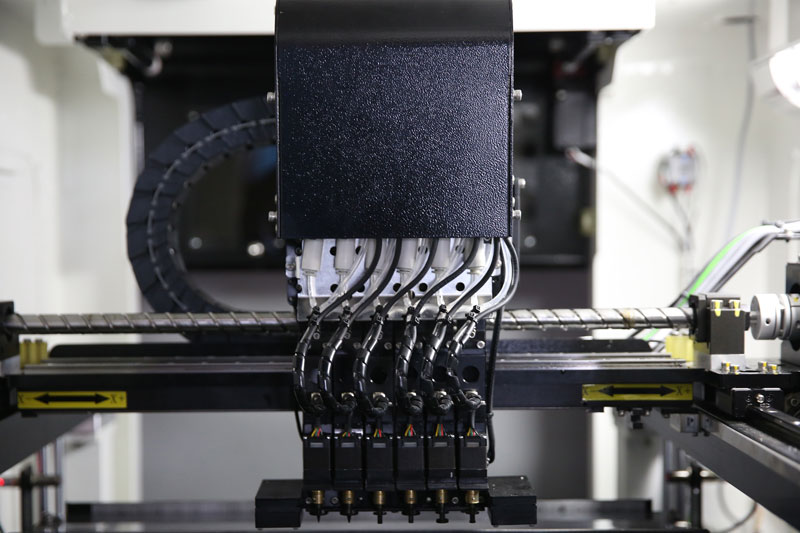

6 Placement Heads

Rotation: +/-180 (360)

Up and down separately, easy to pick up

53 Slots Tape Reel Feeders

Supports electric feeder & pneumatic feeder

high efficiency with flexible, worthiest space

Flying Cameras

Uses imported CMOS sensor

Ensure the stable and durable effects

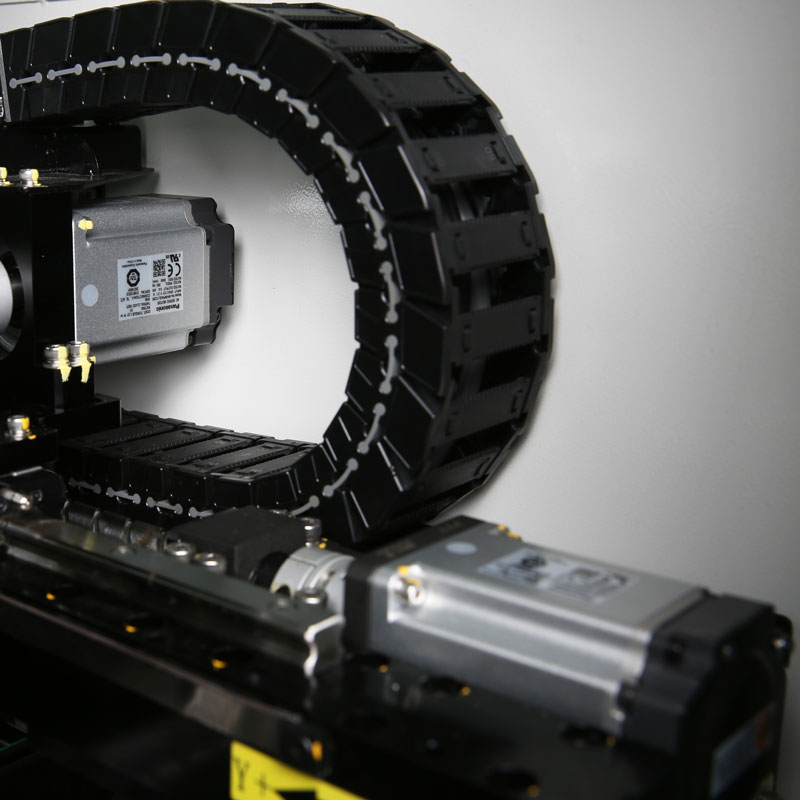

Drive Motor

Panosonic 400W servo motor

Ensure better torque and acceleration

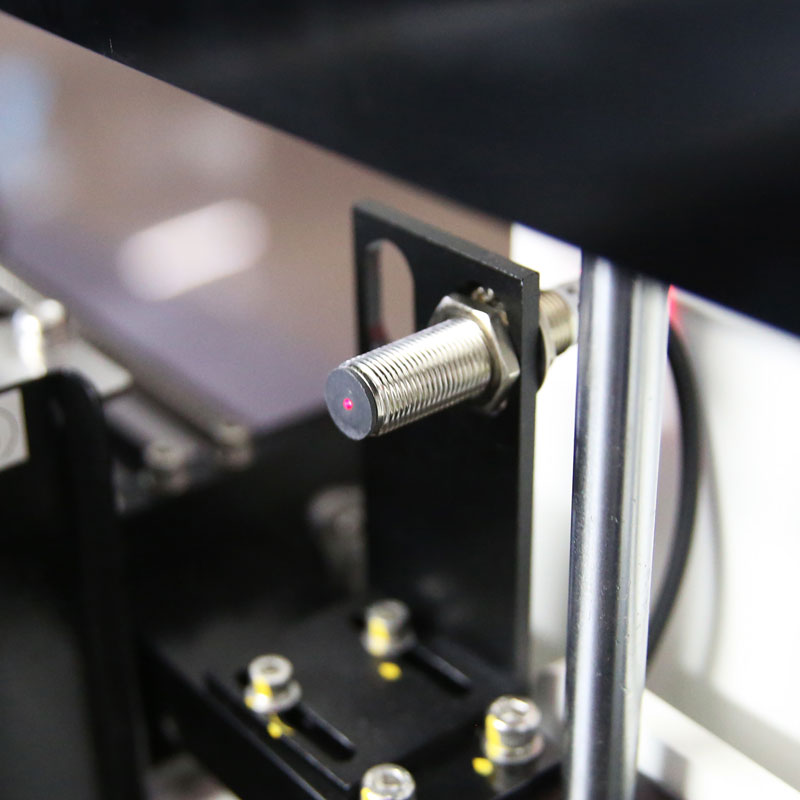

Patent Sensors

Avoid head bumps and abnormalities

by misoperation

C5 precision ground screw

Less wear and aging

Stable and durable precision

If you need, please feel free to contact us for more information.

Our Service

We are in a good position not only to supply you high quality pnp machine , but also the excellent after sales service.

Well-trained engineers will offer you any technical support.

10 engineers powerful after-sales service team can respond customers queries and enquiries within 8 hours.

Professional solutions can be offered within 24 hours both workday and holidays.

About us

Factory

Zhejiang NeoDen Technology Co., LTD., founded in 2010, is a professional manufacturer specialized in SMT pick and place machine, reflow oven, stencil printing machine, SMT production line and other SMT Products. We have our own R & D team and own factory, taking advantage of our own rich experienced R&D, well trained production, won great reputation from the world wide customers.

① Established in 2010, 200+ employees, 8000+ Sq.m. factory

② NeoDen products: Smart series PNP machine, NeoDen K1830, NeoDen4, NeoDen3V, NeoDen7, NeoDen6, TM220A, TM240A, TM245P, reflow oven IN6, IN12, Solder paste printer FP2636, PM3040

③ Successful 10000+ customers across the globe

Certification

Exhibition

FAQ

Q1: May I know what’s the nearest airport from your company? in case I visit your company.

A: Hangzhou Airport is the nearest, welcome to visit us.

Q2: What about the lead time for mass production?

A: Honestly, it depends on the order quantity and the season you place the order.

Alway 15-30 days based on general order .

Q3: How many workers in your factory?

A: More than 200 workers.

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.