SMT Stencil Printer

SMT Stencil Printer

Specification

| Product name | SMT Stencil Printer |

| Maximum board size(X x Y) | 450mm x 350mm |

| Minimum board size(X x Y) | 50mm x 50mm |

| PCB thickness | 0.4mm~6mm |

| Warpage | ≤1% Diagonal |

| Maximum board weight | 3Kg |

| Board margin gap | Configuration to 3mm |

| Maximum bottom gap | 20mm |

| Transfer speed | 1500mm/s(Max) |

| Transfer height from the ground | 900±40mm |

| Transfer orbit direction | L-R,R-L,L-L,R-R |

| Machine weight | Appro.1000Kg |

Feature

Standard Configuration

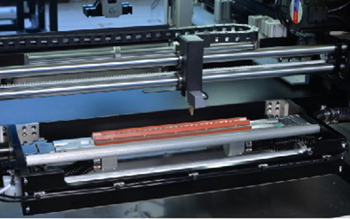

1. High efficiency and high adaptability stencil cleaning system.

The new wiping system ensures full contact with the stencil;

three cleaning methods of dry, wet and vacuum, and free combination can be selected;

soft wear-resistant rubber wiping plate, thorough cleaning, convenient disassembly, and universal length of wiping paper.

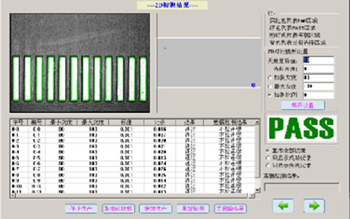

2. 2D solder paste printing quality inspection and SPC analysis

The 2D function can quickly detect the printing defects such as offset, less tin, missing printing and connecting tin, and the detection points can be increased arbitrarily; SPC software can ensure the printing quality through the sample analysis machine CPK index collected by the machine.

Options Configuration

1. Automatic dispensing function

According to different printing process requirements, after printing, the PCB can be carry out accurate dispensing, tin dispensing,ine drawing, filling and other functional operations.

2. Detection function on Stencil

By compensating the light source above the steel stencil, CCD is used to check the mesh in real time, so as to quickly detect and judge whether the mesh is blocked after cleaning, and carry out automatic cleaning, which is a supplement to the 2D detection of PCB.

Provide one-stop SMT assembly production line

Related products

FAQ

Q1: Which payment form you can accept?

A: T/T, Western Union, PayPal etc. We accept any convenient and swift payment term.

Q2: What’s is your shipping service?

A: We can provide services for vessel booking, goods consolidation, customs declaration, shipping documents preparation and delivery bulk at the shipping port.

Q3: What’s your tem of the delivery?

A: Our ordinary delivery term is FOB Shanghai.

We also accept EXW, CFR, CIF, DDP, DDU etc. We’ll offer you the shipping charges and you can choose the one which is the most convenient and effective for you.

About us

Factory

Owned the own machining center, skilled assembler, tester and QC engineers, to ensure the strong abilities for NeoDen machines manufacturing, quality and delivery;

40+ global partners covered in Asia, Europe, America, Oceania and Africa, to successfully serve 10000+ users in all of the world, to ensure the better and faster local service and prompt response;

3 different R&D teams with total 25+ professional R&D engineers, to ensure the better and more advanced developments and new innovation.

Certification

Exhibition

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.