SMT Small Pick and Place Machine

NeoDen4

SMT Small Pick and Place Machine

The fourth-generation model

Description

Specification

| Product name | SMT Small Pick and Place Machine |

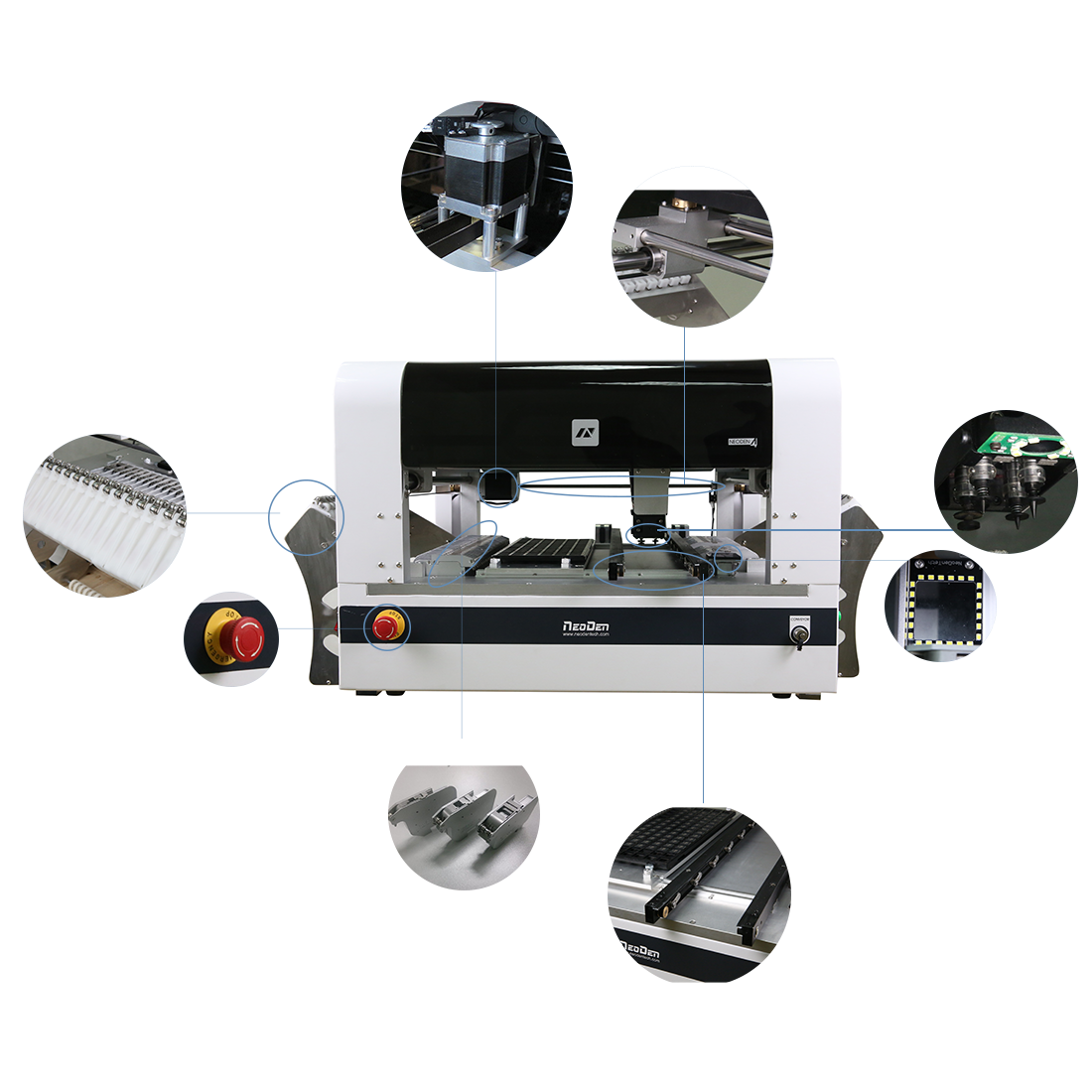

| Machine Style | Single gantry with 4 heads |

| Placement Rate | 4000 CPH |

| External Dimension | L 870×W 680×H 480 mm |

| Max applicable PCB | 290mm*1200mm |

| Feeders | 48pcs |

| Average working power | 220V/160W |

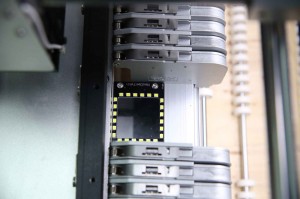

| Component Range | Smallest Size: 0201 |

| Biggest Size: TQFP240 | |

| Max Height: 5mm |

Feature

This machine is adopted dual cameras, four heads, auto rails, electronic feeder, two conveyor ports, which achieves high accuracy, simple structure, stable performance and easy operation.

This manual cover installation, setup, customization and operation of the NeoDen4 pick and place machine.

Please read this manual in its entirety before working on the machine.

Populating PCBs with surface mount technology (SMT) can be as challenging as the circuit design itself, and the NeoDen4 provides the user with all the tools necessary to work with a wide variety of components in a wide variety of packaging.

The NeoDen4 is not a knock-off.

Details

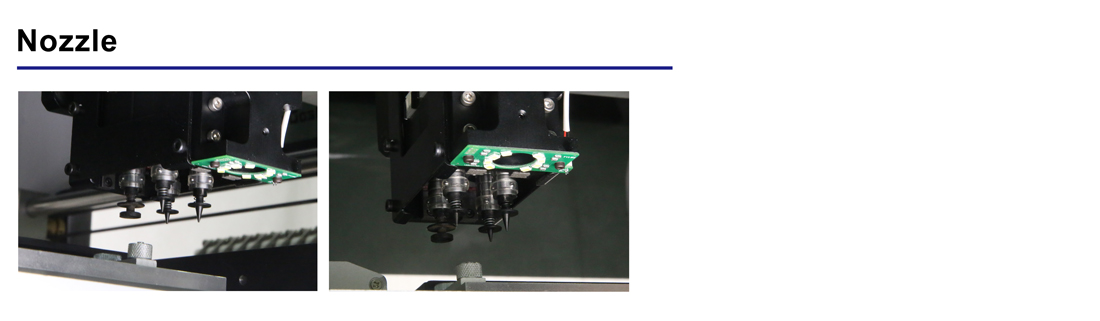

Any size nozzle can be installed in any of the four locations in the head, so a single machine can handle all of the necessary components without the need for nozzle changes.

The spring-loaded nozzles simply snap in and pull out of the head.

Any Nozzle can be installed in any of the four locations on the head.

Installed with high speed industry cameras,enables cameras can recognize and align different component for four mounting heads.

With the help of upper-camera and down looking camera, they will display the picking process with high definition image, meet almost all of PCB's producing requirements.

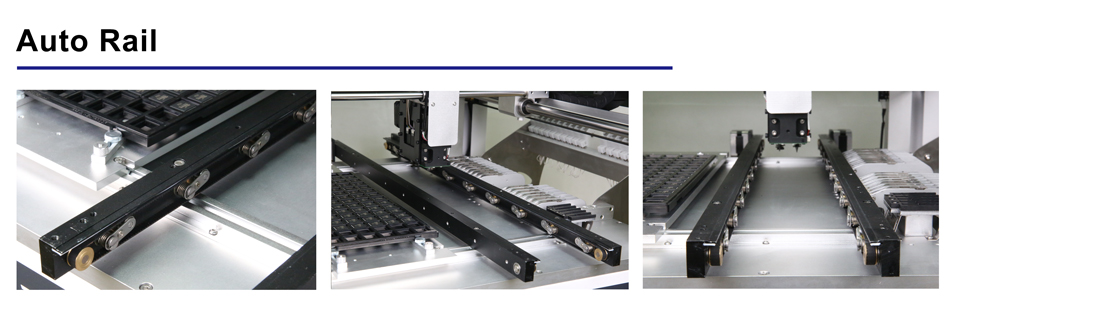

The rail system allows automatic feeding of PCBs, automatic alignment of the board with the camera, and automatic ejection from the front of the machine or the rear.

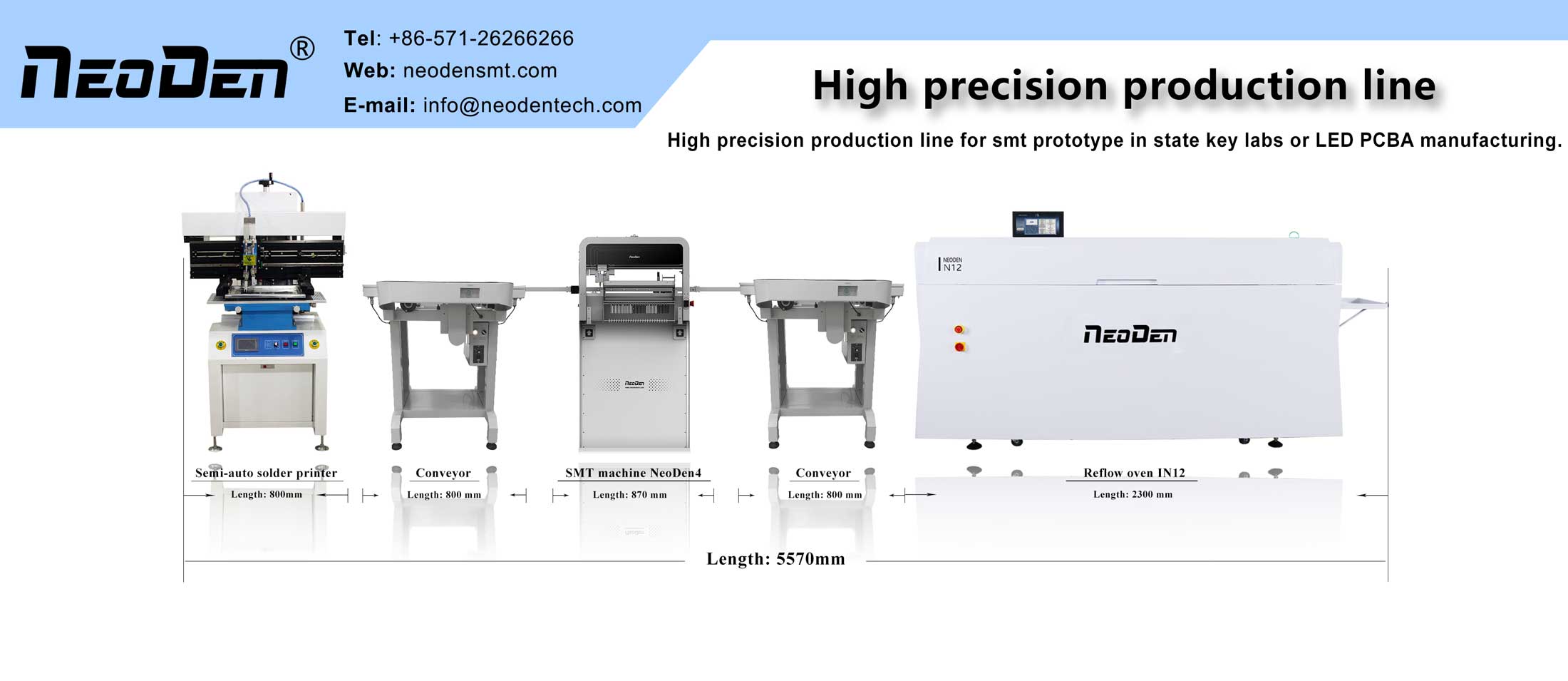

Rear-ejection is useful when the machine is connected to an optional conveyor that can deliver the finished board directly to the reflow oven or to another NeoDen4.

The NeoDen4 can accommodate up to 48 8mm tape-and-reel feeders on its left and right rails, and any size feeder (8, 12, 16 and 24mm) can be installed in any combination or order on the left and right sides of the machine.

Any area of the table may be used for components awaiting placement, or for the board under manufacture.

Package

If you need, please feel free to contact us for more information.

About us

Factory

① Established in 2010, 200+ employees, 8000+ Sq.m. factory

② Successful 10000+ customers across the globe

③ Listed with CE and got 50+ patents

④ 30+ quality control and technical support engineers, 15+ senior international sales, timely customer responding within 8 hours, professional solutions providing within 24 hours

Certification

Exhibition

FAQ

Q1: What’s the payment terms?

A:100% T/T in advance.

Q2: When did your factory established?

A: Since 2010

Q3: Is there the products tested before shipping?

A: Yes, of course.

All of our conveyor belt we all will has been 100% QC before shipping. We test every batch every day.

One Stop SMT Equipments Manufacturer

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.