SMT reflow soldering equipment reflow oven

NeoDen IN6 SMT reflow soldering equipment reflow oven

Specifications

| Product Name | NeoDen IN6 SMT reflow soldering equipment reflow oven |

| Power requirement | 110/220VAC 1-phase |

| Power max. | 2KW |

| Heating zone quantity | Upper3/ down3 |

| Conveyor speed | 5 - 30 cm/min (2 - 12 inch/min) |

| Standard Max Height | 26mm |

| Temperature control range | Room temperature~300 degree celsius |

| Temperature control accuracy | ±0.2 degree celsius |

| Temperature distribution deviation | ±1 degree celsius |

| Soldering width | 260 mm (10 inch) |

| Length process chamber | 680 mm (26.8 inch) |

| Heat-up time | approx. 25 min |

| Dimensions | 1020*507*350mm(L*W*H) |

| Packing Size | 112*62*56cm |

| N.W./ G.W. | 49KG/64kg (without working table) |

Our Service

1. We are in a good position not only to supply you high quality pnp machine , but also the excellent after sales service.

2. Well-trained engineers will offer you any technical support.

3. 10 engineers powerful after-sales service team can respond customers queries and enquiries within 8 hours.

4. Professional solutions can be offered within 24 hours both workday and holidays.

Features

6 heating zones

1. 6 zones design, light and compact.

2. Smart control with high sensitivity temperature sensor, the temperature can be stabilized within + 0.2℃.

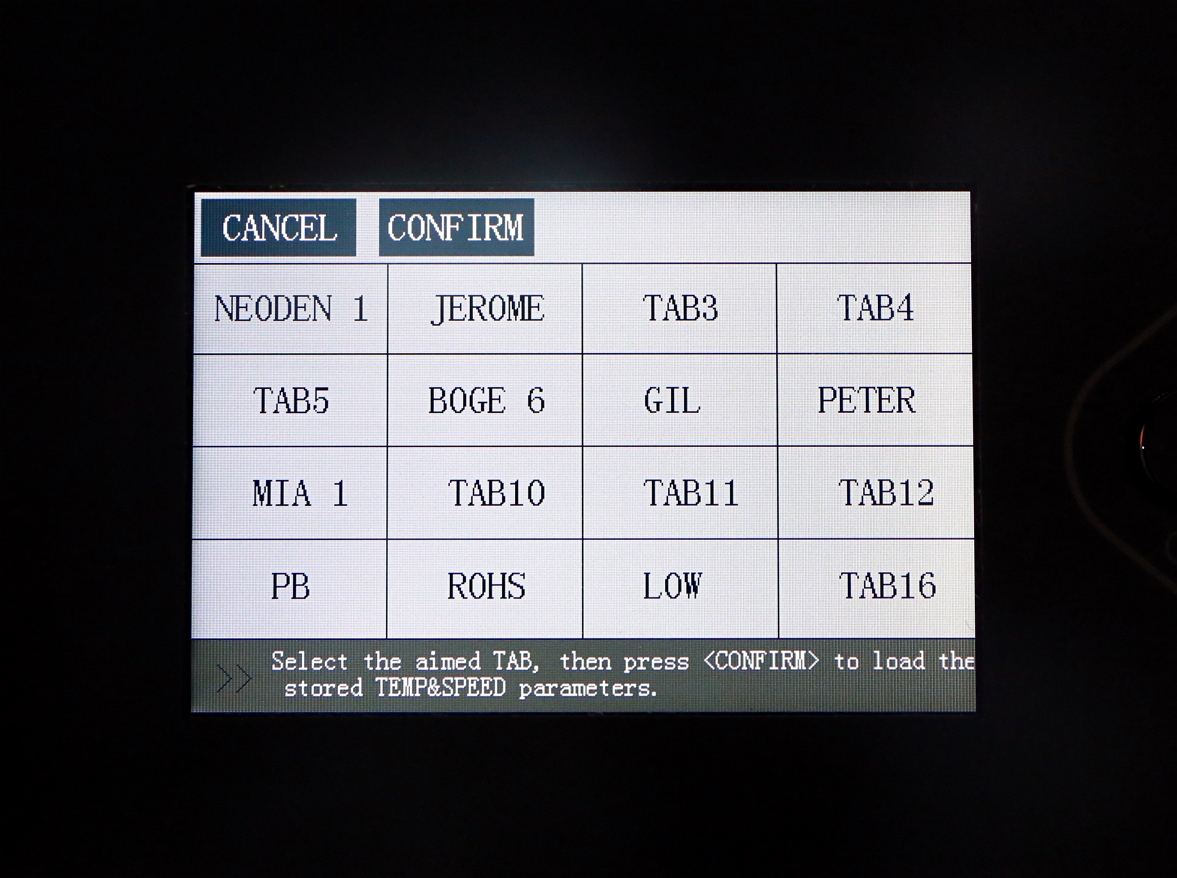

Intelligent control system

1. Smart control with high sensitivity temperature sensor, the temperature can be stabilized within + 0.2℃.

2. Several working files can be stored, freely switch between Celsius and Fahrenheit, flexible and easy to understand.

3. PCB soldering temperature curve can be displayed based on real-time measurement.

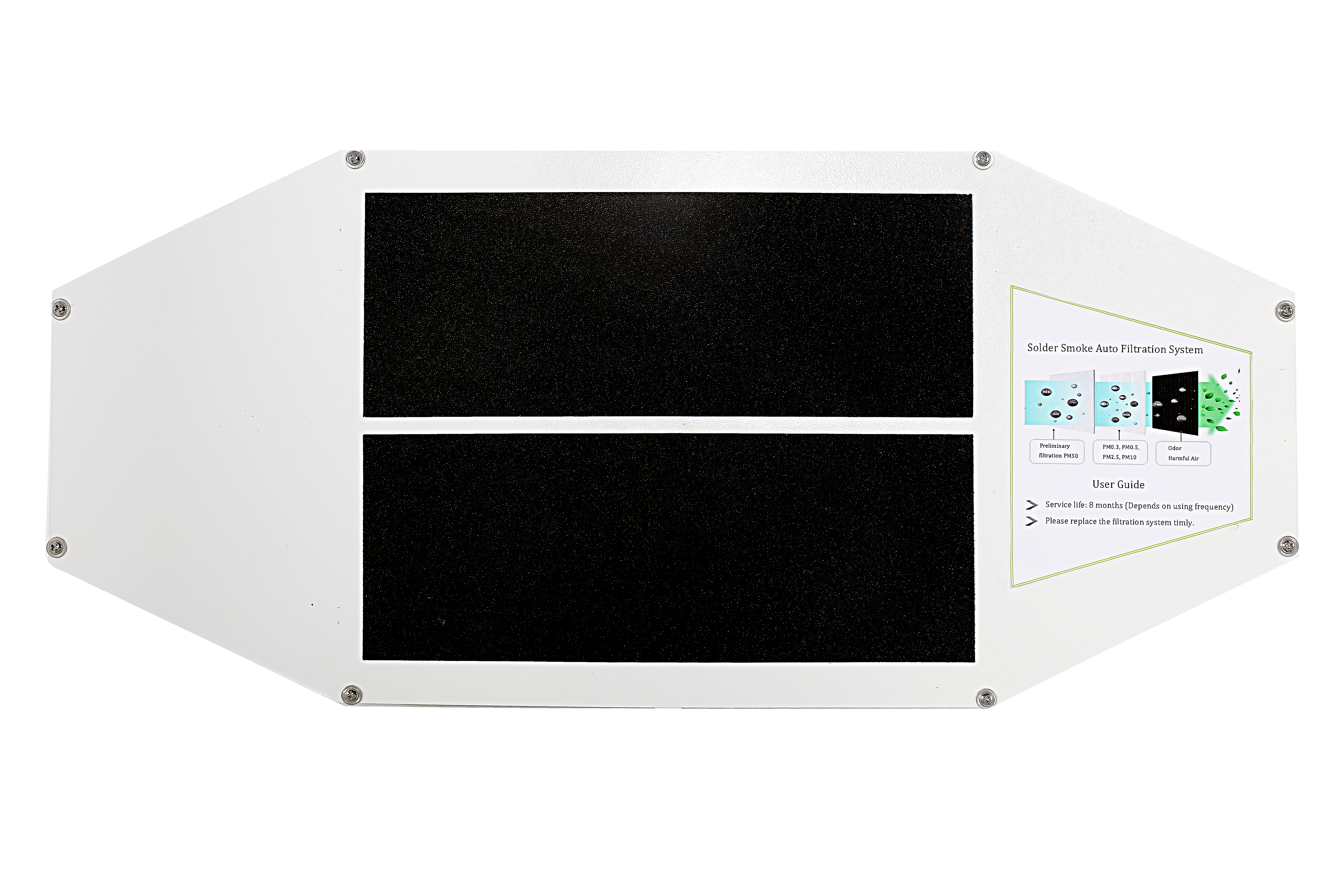

Saving energy and Eco-friendly

1. Original built-in soldering smoke filtering system, elegant appearance and eco-friendly.

2. Household power supply, convenient and practical.

3. Reinforced heavy-duty carton package, light-weight and environment-friendly.

Provide one-stop SMT assembly production line

Related products

FAQ

Q1: How can I buy machine from you?

A: (1) Consult us on line or by e-mail.

(2) Negotiate and confirm the final price , shipping , payment method and other terms.

(3) Send you the perfroma invoice and confirm your order.

(4) Make the payment according to the method put on proforma nvoice.

(5) We prepare your order in terms of the proforma invoice after confirming your full payment. And 100% quality check before shipping.

(6) Send your order via express or by air or by sea.

Q2: What we can do for you?

A: Total SMT Machines and Solution, professional Technical Support and Service.

Q3: Can we customize the machine?

A: Of course. All of our machines can be customized.

About us

Exhibition

Certification

Factory

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.