SMT Reflow Ovens

NeoDen IN8C SMT Reflow Ovens

Product Overview

Brand

Country/Region of Manufacture

Heating zone quality

Conveyor speed

Welding Height

NeoDen

China

Upper4/Down4

5-60cm/min

Up30mm, Down 20mm

Model

Application

Soldering width

Dimensions

Weight

NeoDen IN8C SMT Reflow Ovens

PCB soldering, SMT reflow

330mm

1660*607*1075mm (vertical)

200Kg

Description

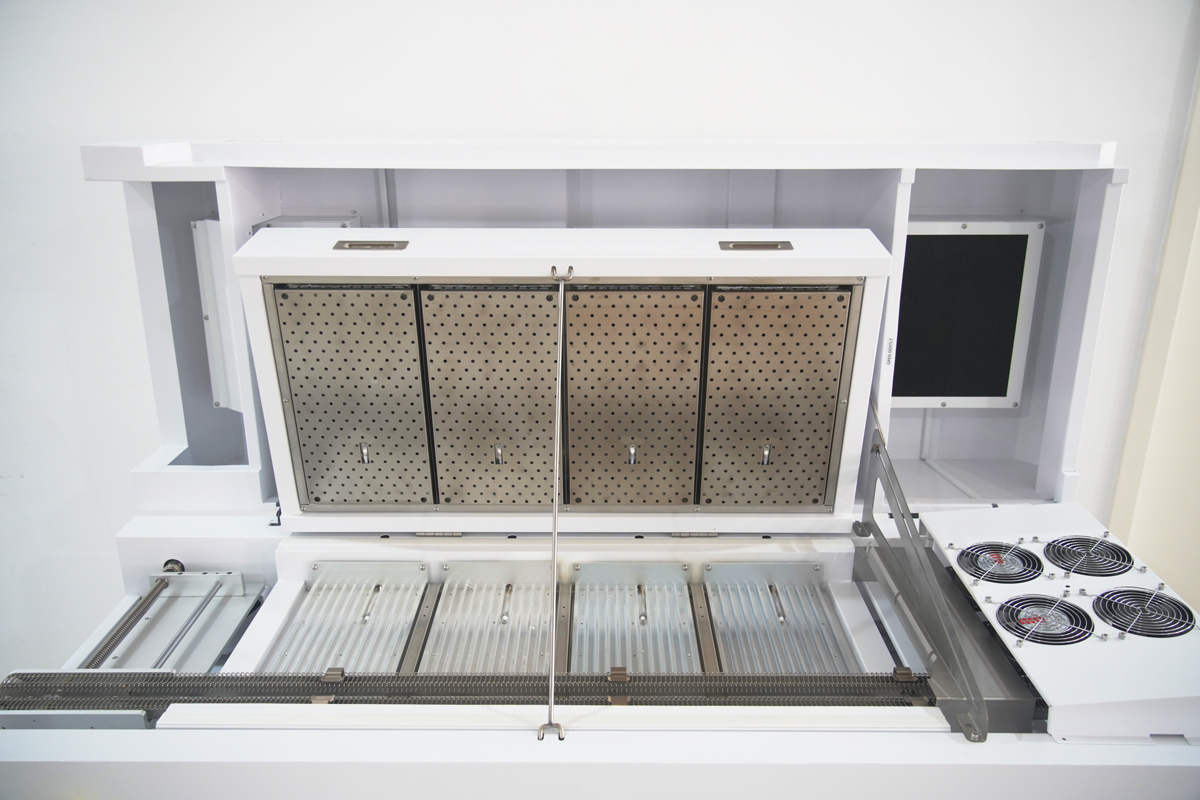

1. NeoDen IN8C SMT reflow ovens independent circulating air design of the cooling area, completely isolated from the external environment on the internal temperature cavity.

2. The control system has the characteristics of high integration, timely response, low failure rate, easy maintenance, etc.

3. Unique heating module design, with high precision temperature control, uniform temperature distribution in the thermal compensation area, high efficiency of thermal compensation, low power consumption and other characteristics.

Details

8 Heating Zones

8 temperature zones compact design

Lightweight and compact

Cooling zone

Independent circulating air design

Isolates the influence of the external environment

Energy saving & Eco-friendly

1-Built-in welding smoke filtering system, effective filtration of harmful gases.

2-Energy saving, low power consumption, low power supply requirements, the ordinary civil electricity can meet the use.

Track

Light weight, small heat loss

Maintenance free and permanent service life

Specification

|

Model |

NeoDen IN8C SMT Reflow Ovens |

|

Transmission mode |

track |

|

Temperature zones |

Up4/Down4 |

|

Heating mode |

Nickel chromium alloy wire and aluminum alloy heating |

|

Cooling zone |

Upper 4 fan |

|

Speed |

5-60cm/min |

|

Welding height |

Up30MM Down20MM |

|

Temperature range |

Room temperature ~ 300 ℃ |

|

Heating time |

~20-30 minutes |

|

Maximum PCB size |

330mm |

|

Equipment size |

L1660*W612*H500(Desktop)L1660*W607*H1075(vertical) |

|

Starting power |

~3.6KW |

|

Working power |

~1.5KW |

|

Voltage |

220V |

|

Track direction |

From left to right |

|

Weight |

200KG |

Our Service

1. Good knowledge on different market can meet special requirements.

2. Real manufacturer with our own factory located in Huzhou, China

3. Strong professional technical team ensure to produce the top quality products.

4. Special cost control system ensure to provide the most favorable price.

5. Rich experience on SMT area.

About us

Factory

Zhejiang NeoDen Technology Co., LTD., founded in 2010, is a professional manufacturer specialized in SMT pick and place machine, reflow oven, stencil printing machine, SMT production line and other SMT Products. We have our own R & D team and own factory, taking advantage of our own rich experienced R&D, well trained production, won great reputation from the world wide customers.

1. Successful 10000+ customers across the globe.

2. 30+ Global Agents covered in Asia, Europe, America, Oceania and Africa.

3. R&D Center: 3 R&D departments with 25+ professional R&D engineers.

4. Listed with CE and got 50+ patents.

5. 30+ quality control and technical support engineers, 15+ senior international sales, timely customer responding within 8 hours, professional solutions providing within 24 hours.

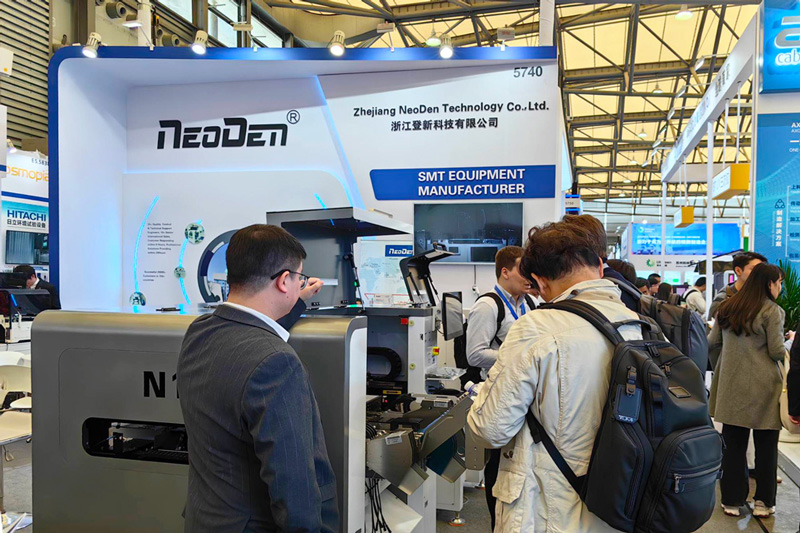

Exhibition

Certification

FAQ

Q1. What is your advantage compared with your competitors?

A. (1). Qualified Manufacturer

(2). Reliable Quality Control

(3). Competitive Price

(4). High Efficiency working (24*7hours)

(5). One-Stop Service

Q2. What we can do for you?

A. Total SMT reflow oven and SMT solution, professional technical support and service.

Q3. What products you sell?

A. Our company deal in the following products.

PCB production line equipments

Solder stencil printer, SMT AOI machine, SMT SPI machine, SMT X-Ray machine, pick and place machine

SMT accessories

Feeders, Feeder parts, SMT nozzles

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.