SMT pick N place machine tabletop

NeoDen 3V SMT pick N place machine tabletop Video

NeoDen 3V SMT pick N place machine tabletop

Description

Brief Introduction

Specification

| Machine Style | Single Gantry with 2 heads | Model | NeoDen 3V Advanced |

| Placement Rate | 3,500 CPH | Placement Accuracy | +/-0.02 mm |

| Feeder Capacity | Max Tape Feeder: 44 pcs (All 8mm width) | Alignment | Stage Vision |

| Vibration Feeder: 5 | Component Range | Smallest Size: 0402 | |

| Tray Feeder: 5-10 | Biggest Size: TQFP144 | ||

| Rotation | +/-180° | Max Height: 5 mm | |

| Electricity Supply | 110V/220 V | Placement Area | 350x410 mm |

| Power | 160~200 W | Machine Size | L820×W680×H410 mm |

| Net Weight | 60 Kg | Packing Size | L1010×W960×H580 mm |

Product Details

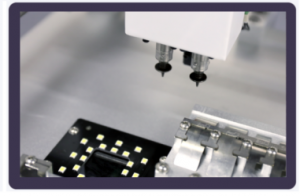

Full Vision 2 head system

2 high-precision placement heads with

±180° rotation satisfy the need of wide range components

Patented Automatic Peel-box

Feeder Capacity: 24*Tape feeder(all 8mm),

5*Vibration feeder, 10* IC Tray feeder

Flexible PCB positioning

By using PCB support bars and pins, wherever you want

to put the PCB and whatever the shape of your PCB is.

Integrated Controller

More stable performance and easier to do maintenance.

Accessories

| 1. Pick and Place Machine NeoDen3V-A | 1 | 2. PCB support bar | 4 units |

| 3. PCB support pin | 8 units | 4. Electromagnet | 1 pack |

| 5. Needle | 2 sets | 6. Allen wren set | 1 |

| 7. Tool box | 1 unit | 8. Cleaning needle | 3units |

| 9. Power cord | 1 unit | 10. Double side adhesive tape | 1 set |

| 11. Silicon tube | 0.5m | 12. Fuse(1A) | 2 units |

| 13. 8G flash drive | 1 unit | 14. Reel holder stand | 1 set |

| 15. Nozzle rubber 0.3mm | 5 units | 16. Nozzle rubber 1.0mm | 5 units |

| 17. Vibration feeder | 1 unit |

Quality Control

We have QC person stay on the production lines do to the inspection.All products must have been inspected before delivery.we do inline inspection and final inspection.

1. All raw material checked once it arrive our factory.

2. All pieces and logo and all details checked during production.

3. All packing details checked during production.

4. All production quality and packing checked on final inspection after finished.

Provide one-stop SMT assembly production line

Related Products

Comparison of similar products

FAQ

Q1: What's your products?

A: SMT machine, AOI, reflow oven,PCB loader, stencil printer.

Q2: What’s the MOQ for your products?

A: Usually 1 set.

Q3: What's the payment terms?

A: 100% T/T in advance.

About us

If you need, please feel free to contact us for more information!

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.