SMT Pick and Place Machine

SMT Pick and Place Machine video

SMT Pick and Place Machine

Features

1. 8 Synchronized Nozzles which ensure a repeatable placement accuracy with high speed.

2. Ethernet communication interface for all internal signal travel makes the machine to perform more stable and flexible.

3. Picking location of pneumatic feeder can be calibrated automatically and promptly, to ensure easy operation and high efficiency.

Specification

Product name: SMT Pick and Place Machine

Model: NeoDen K1830

Tape width: 8mm, 12mm, 16mm, 24mm, 32mm, 44mm, 56mm

IC Tray Capacity: 10

Smallest Component size: 0201 (electronic feeder)

Applicable Components: 0201, Fine-pitch IC, Led Component, Diode, Triode

Component Height Maximum: 18mm

Applicable PCB size: 540mm*300mm (1500 optinal)

Power Supply: 220V, 50Hz (convertible to 110V)

Air source: 0.6MPa

N.W./G.W: 280/360Kgs

Product Detail

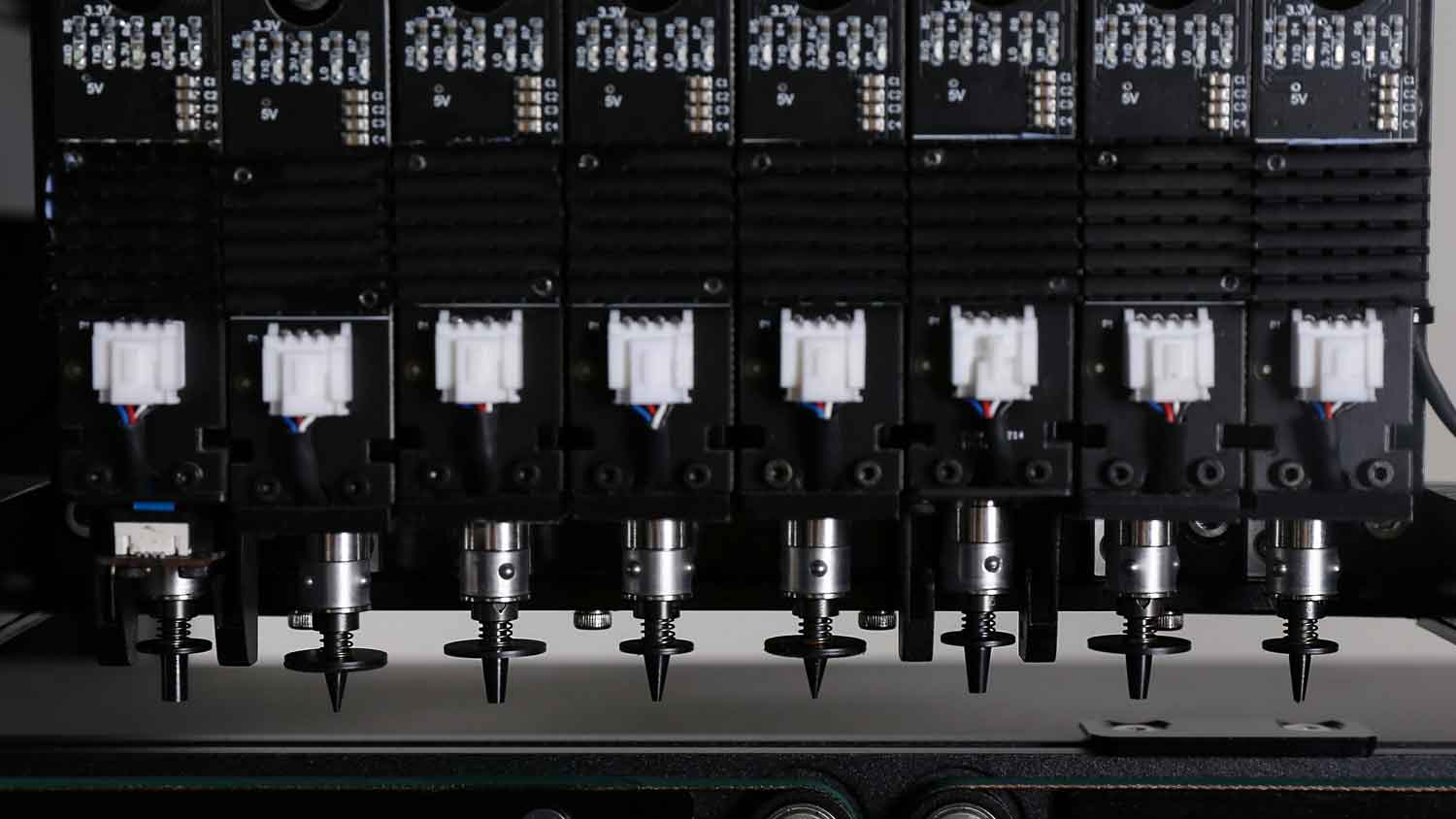

8 heads with Vision enabled

Rotation: +/-180 (360)

High speed repeatable placement accuracy

66 Reel tape feeders

Be calibrated automatically and promptly

Ensure easy operation and high efficiency

Double mark cameras

Better calibration

Improves the overall speed of the machine

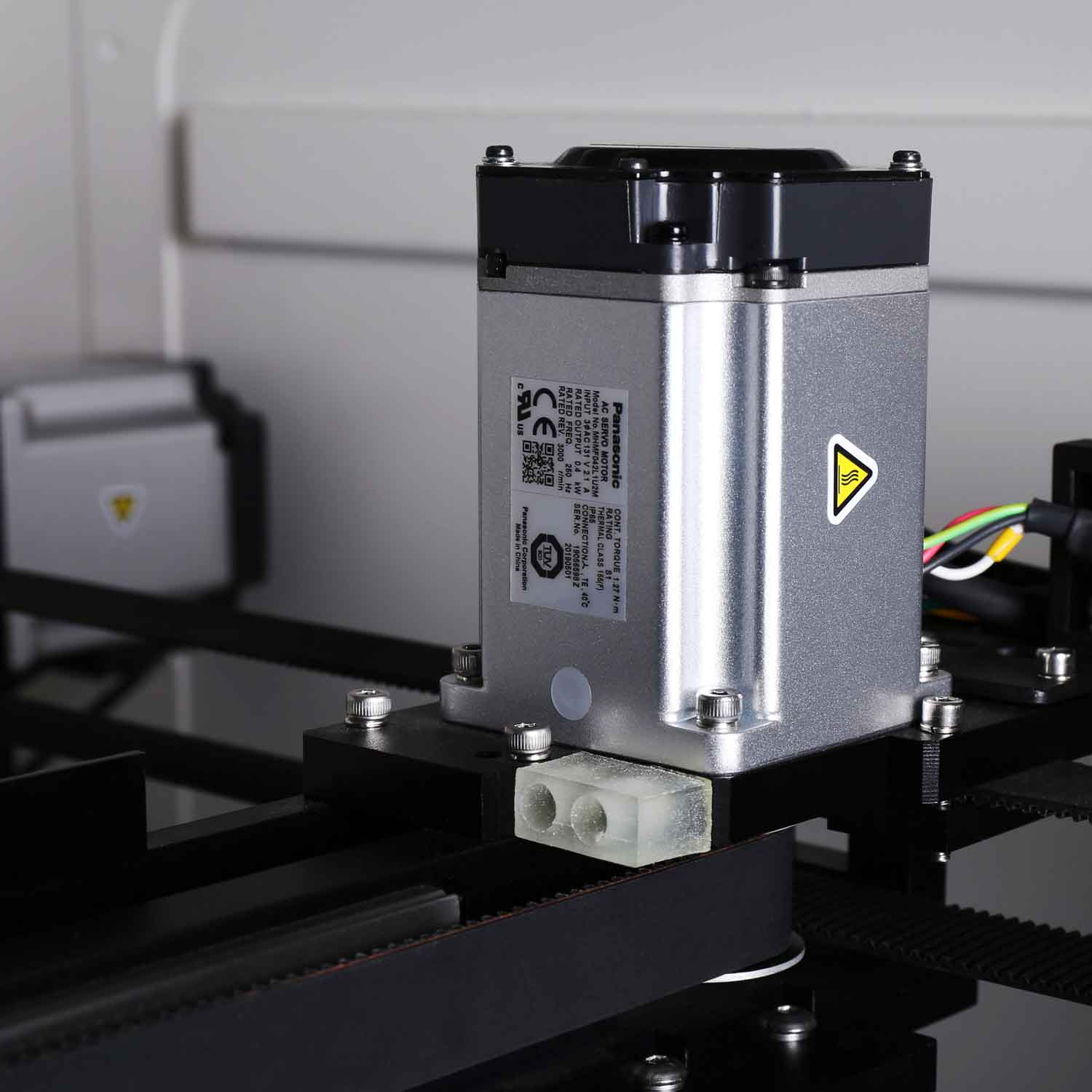

Drive Motor

Panasonic Servo Motor A6

Make the machine to function more accurate

High-definition display

Display size: 12 inch

Makes the machine more convenient to use

Warning light

Triple color of light

Beautiful and elegant indicator design

If you need, please feel free to contact us for more information.

PCB angle

PCB angle detect should be under the mode of Single board and manual programing, PCB angle will influence the accuracy of mounting.

The angle closer to 0 degree the better, and the angel deviation need to be within 1 degree.

The angle of PCB is generated according to panelized PCB coordinate, but we can also adjust the angle by manual.

Click “Angle Detect” button, according to the index of machine to choose two points, then a new PCB angle will be generated.

(Note, the two points need to be paralleled)

About us

Factory

Certification

Exhibition

FAQ

Q1: This is the first time I use this kind of machine, is it easy to operate?

A: We have English user manual and guide video to teach you how to use the machine. If still have question, pls contact us by email / skype / whatapp / phone / trademanager online service.

Q2: What products you sell?

A: Our company deal in the following products:

SMT equipment

SMT accessories: Feeders, Feeder parts

SMT nozzles, nozzle cleaning machine, nozzle filter

Q3: Is it hard to use these machines?

A: No,not hard at all. For our previous clients, at most 2 days is enough to learn to operate the machines.

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.