SMT LED Placement Machine

SMT LED Placement Machine

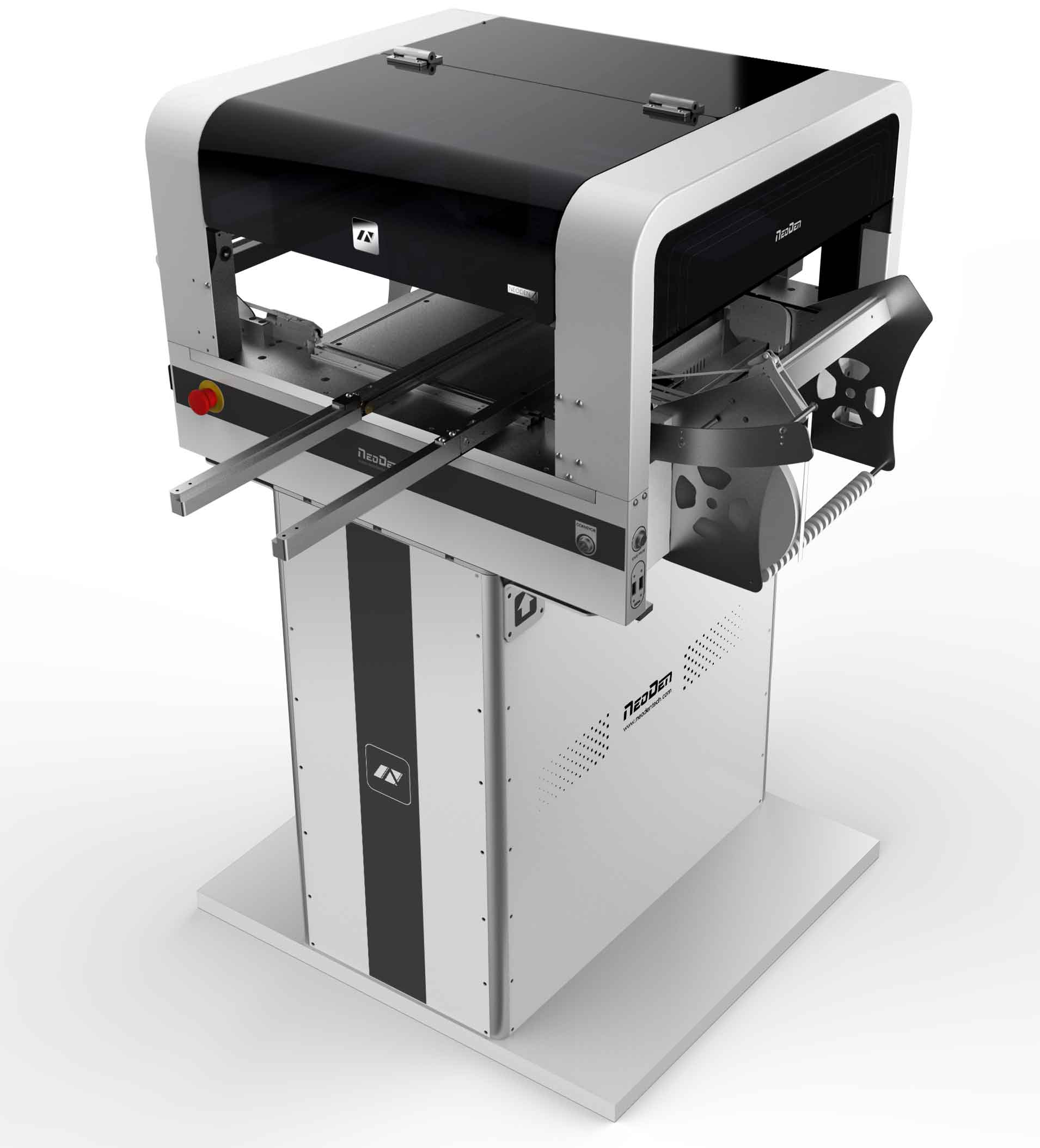

The fourth-generation model

Description

Specification

| Product name | SMT LED Placement Machine |

| Machine Style | Single gantry with 4 heads |

| Placement Rate | 4000 CPH |

| External Dimension | L 870×W 680×H 480 mm |

| Max applicable PCB | 290mm*1200mm |

| Feeders | 48pcs |

| Average working power | 220V/160W |

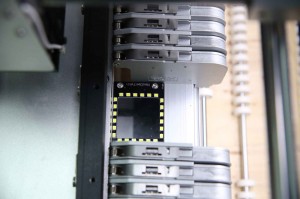

| Component Range | Smallest Size: 0201 |

| Biggest Size: TQFP240 | |

| Max Height: 5mm |

Details

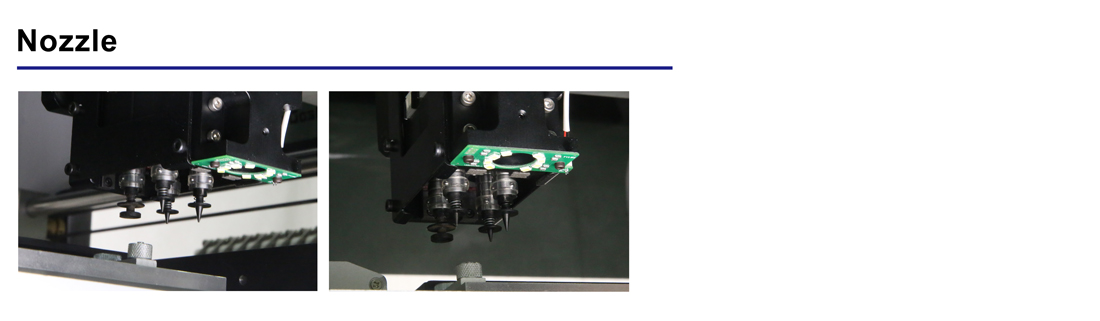

Any size nozzle can be installed in any of the four locations in the head, so a single machine can handle all of the necessary components without the need for nozzle changes.

The spring-loaded nozzles simply snap in and pull out of the head. Any nozzle can be installed in any of the four locations on the head.

The downward-looking camera

On the head is used for precision location of feeders and PCB placement points.

The upward-looking camera

Located on the right side of the machine. When enabled, this camera first ensures that a component is attached to the proper nozzle.

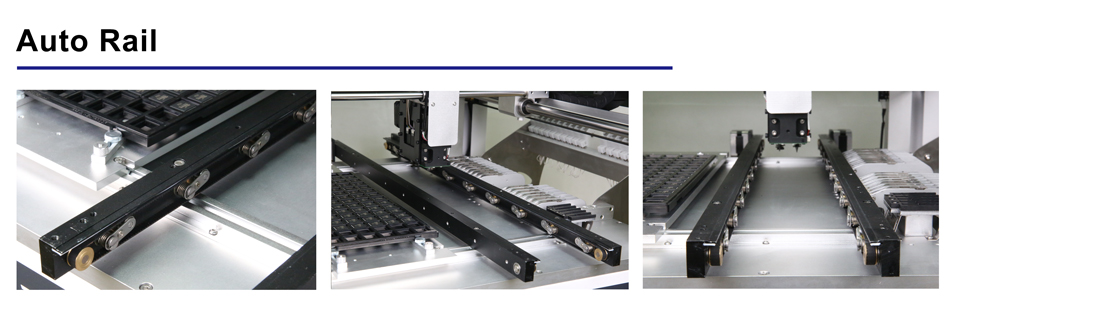

The rail system allows automatic feeding of PCBs, automatic alignment of the board with the camera,

and automatic ejection from the front of the machine or the rear.

Rear-ejection is useful when the machine is connected to an optional conveyor that can deliver the finished board directly to the reflow oven or to another NeoDen4.

Electric tape-and-reel feeders, vibration feeders and virtual tray feeders are all supported.

Because of the flexibility of the architecture, and the need to work with affordable quantities of parts,

short tapes can also be configured on the machine’s bed.

Package

If you need, please feel free to contact us for more information.

Our Service

Provide product instructions

YouTube video tutorials

Experienced after-sales technicians, 24 hours online service

With our own manufactory and more than 10 years of experience in SMT industry

We can provide customers with the most cost-effective products

About us

Factory

Zhejiang NeoDen Technology Co., Ltd. with global presence in over 130 countries, the excellent performance, high accuracy and reliability of NeoDen PNP machines make them perfect for R&D, professional prototyping and small to medium batch production. We provide professional solution of one stop SMT equipment.

① Successful 10000+ customers across the globe

② 30+ Global Agents covered in Asia, Europe, America, Oceania and Africa

③ 30+ quality control and technical support engineers, 15+ senior international sales, timely customer responding within 8 hours, professional solutions providing within 24 hours

Certification

Exhibition

FAQ

Q1: What’s the payment terms?

A:100% T/T in advance.

Q2: What about the lead time for mass production?

A: Honestly, it depends on the order quantity and the season you place the order.

Alway 15-30 days based on general order.

Q3: Can l visit your factory?

A: By all means, we warmly welcome your arrival. Before you take off from your country, please let us know.

We will show you the way and arrange time to pick you up if possible.

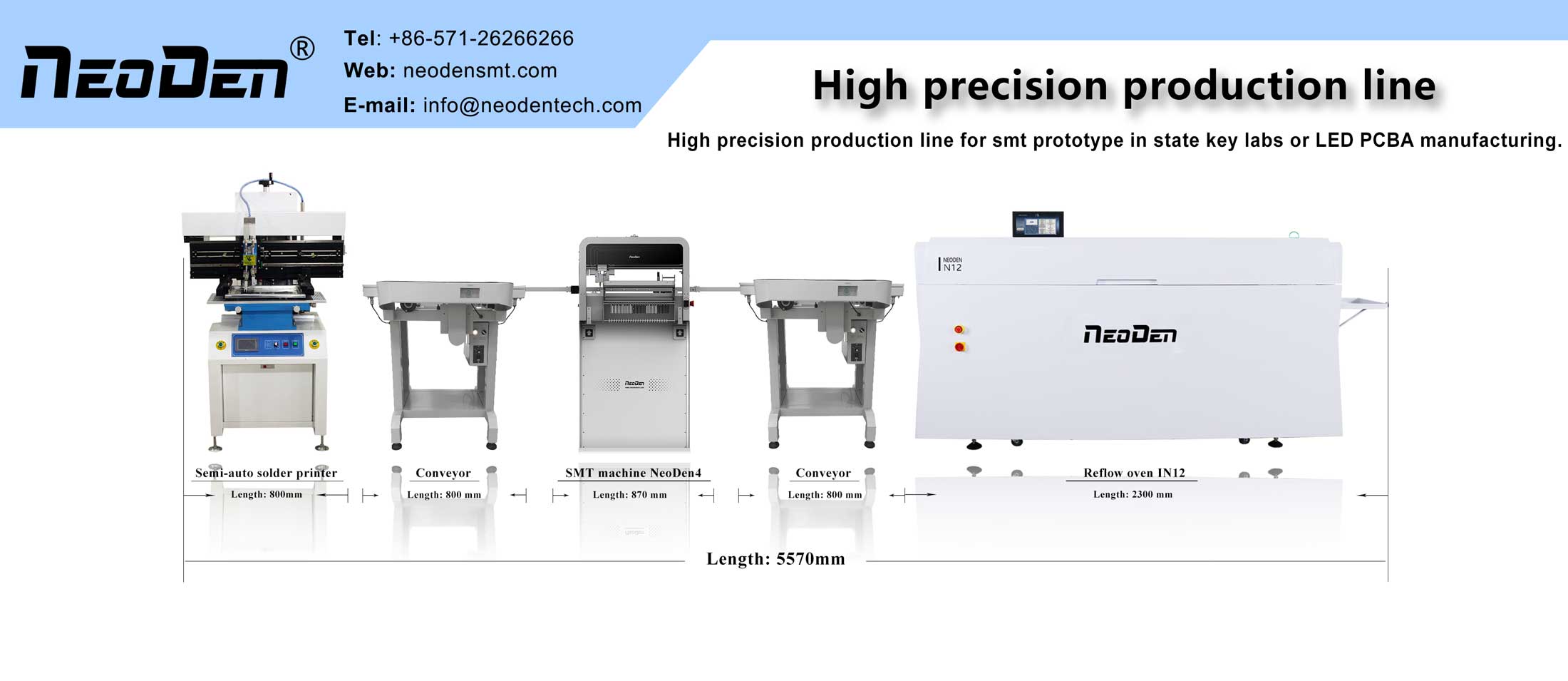

One Stop SMT Equipments Manufacturer

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.