SMT Inspection Machine AOI Testing Equipments

SMT Inspection Machine AOI Testing Equipments

Description

Specification

| Product name | SMT Inspection Machine AOI Testing Equipments |

| Model | ALE |

| PCB Thickness | 0.6mm~6mm |

| Max. PCB Size (X x Y) | 510mm x 460mm |

| Min. PCB Size (Y x X) | 50mm x 50mm |

| Max. Bottom Gap | 50mm |

| Max. Top Gap | 35mm |

| Moving speed | 1500mm/Sec(Max) |

| Transmission height from the ground | 900±30mm |

| Transmission Method | One Stage Lane |

| PCB clamping method | Edge locking substrate clamping |

| Weight | 750KG |

Features

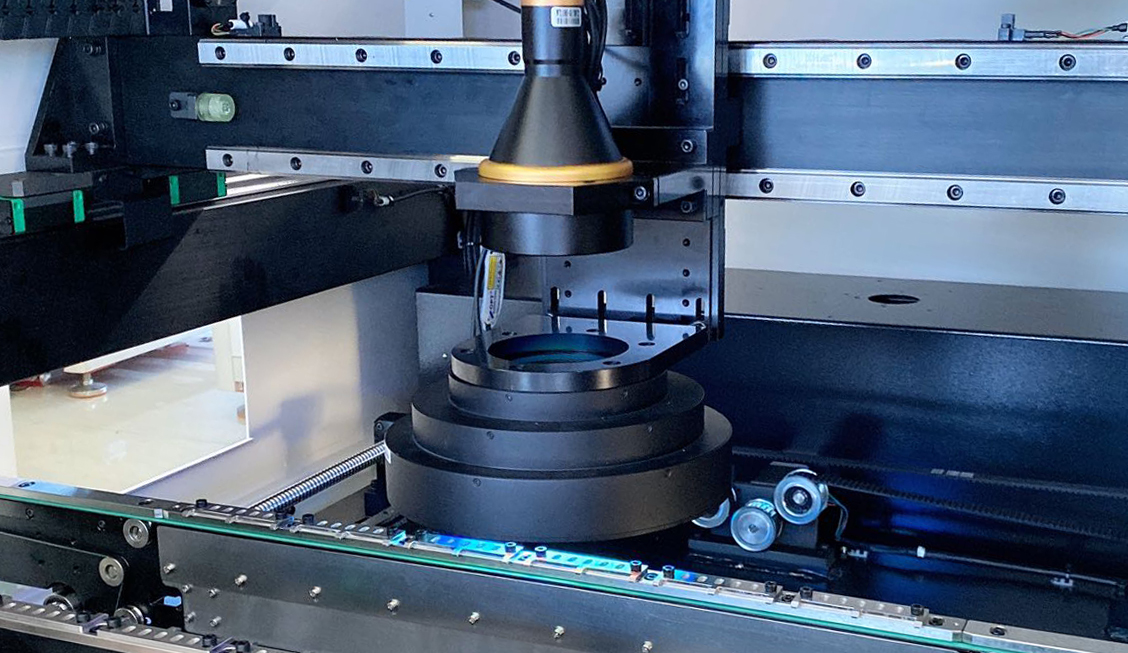

Image Parameters

Camera: GigE Vision(Gigabit network interface)

Resolution: 2448*2048(500 Mega Pixels)

FOV: 36mm*30mm

Resolution: 15μm

Lighting System: Multi-angle surrounding LED light source

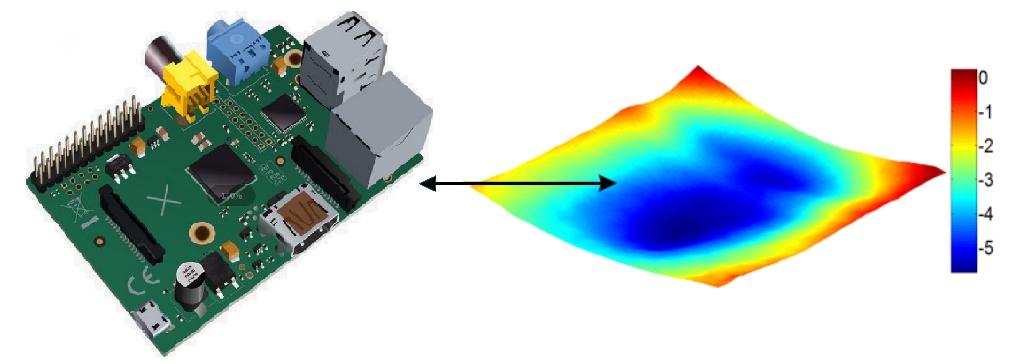

Board Bending Compensation

When the board is unevenly heated, resulting in a certain degree of deformation of the board. The CAD coordinates and the position of the board after passing through the oven cannot be accurately matched. After the plate bending is compensated, the coordinates and the corresponding positions of the components are accurate.

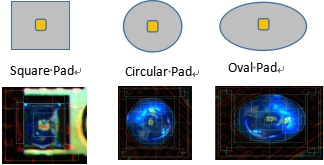

Compatible with Various Shapes of Pads

Wave soldering algorithm supports various shapes of pads, positioning is more accurate.

Machine characteristics

1. HD color global exposure digital camera speed increase 30%.

2. High depth of field telecentric lens, which can measure the solder joints on the side of high components.

3. Support the detection of smt front, back and dip station.

4. Support 0201 and 01005 packaged component inspection.

5. CAD data import, automatic linking component library, automatic color picking.

6. True non-stop offline programming and program update.

7. MES data docking to realize intelligent factory.

8. Support multi-line centralized management and remote service.

Provide one-stop SMT assembly production line

Related Product

FAQ

Q1: Do you provide software updates?

A: Customers who buy our machine, we can offer free upgrades software for you.

Q2: This is the first time I use this kind of machine, is it easy to operate?

A: We have English user manual and guide video to teach you how to use the machine . If still have question, pls contact us by email / skype / whatapp / phone / trademanager online service.

Q3: What products you sell?

A: Our company deal in the following products:

SMT equipment

SMT accessories: Feeders, Feeder parts

SMT nozzles, nozzle cleaning machine, nozzle filter

About us

Exhibition

Certification

Our Factory

If you need, please feel free to contact us!

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.