SMT Equipment

Product Overview

Brand

Country/Region of Manufacture

Speed

Head

Machine dimension

Operation

NeoDen

China

20,000CPH (Max)

8 Heads

1289*1254*1386mm

Automatic

Model

Application

Tape&Reel Feeder

PCB size (Min)

PCB Size (Max)

N10p SMT Equipment

PCB assembly prototype, SMT labs

80pcs (33front+47 rear)

50*50mm

without IC Tray 450*1500mm

with IC Tray 395*1500mm

Description

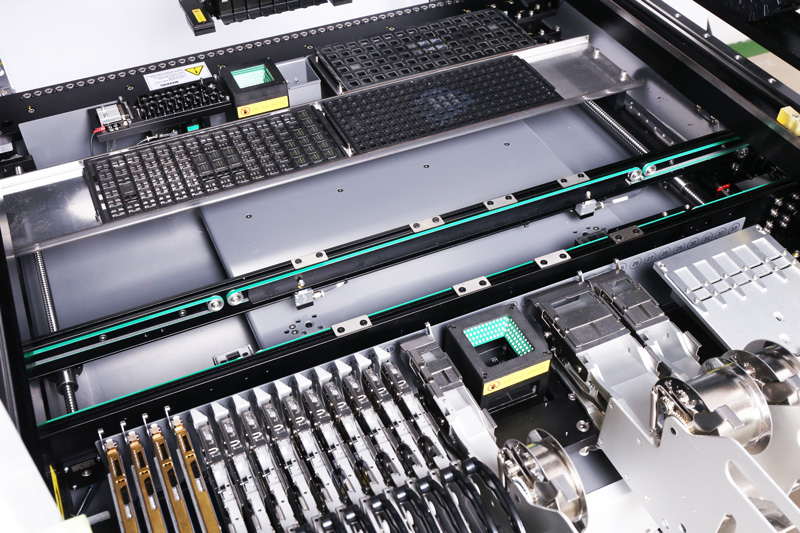

1. N10P SMT equipment support PCB within size (L)1500mm*(W)450mm.

2. Automatic nozzle change function has been added to the system.

39 nozzle positions increase the speed and flexibility of integrated placement.

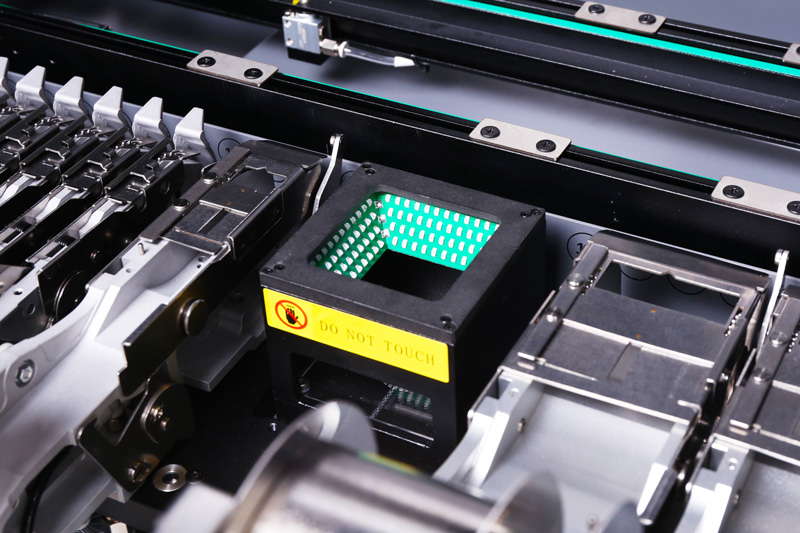

3. IC camera improves the size of IC photos and realizes automatic calibration with automatic nozzle change.

4. Front and rear with 2 fourth generation high speed flying camera recognition systems, US ON sensors, 28mm industrial lens, for flying shots and high accuracy recognition.

5. Automatic calibration of nozzle height, manpower can be utilized efficiently.

| Number of Head | 8 Heads |

| Speed | 20,000CPH (Max) |

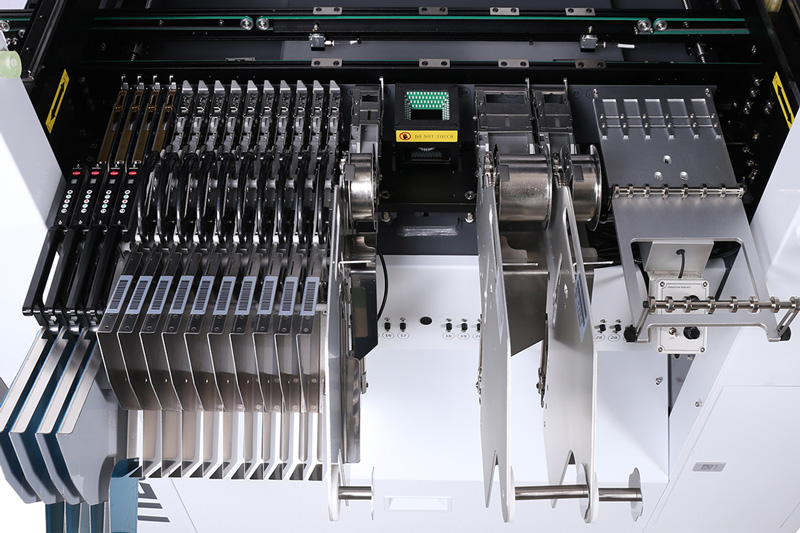

| Feeder Capacity | Tape&Reel Feeder: 80pcs (33 front+47 rear), IC Tray: 1 |

| Automatic Nozzle Change | Yes |

| Position Accuracy | ±0.01mm |

| PCB Thickness | 0.2-3.5mm |

| Power | 600W, Single phase, 220V/110V, 50Hz/60Hz |

| Weight | 1,000Kgs |

| Dimension | 1289*1254*1386mm |

| Packing Size | 1320*1290*1456mm |

| PCB Size | Min: 50*50mm |

| Max: 450*1500mm (without IC Tray) | |

| Max: 395*1500mm (with IC Tray) | |

| Component Range | Flying Camera:0201-22*22mm |

| IC Camera:0201-40*40mm | |

| Max Height: 16mm |

Advantage and Highlights

Support 80 tape feeders, 20 stick feeders and 60 tray feeders, which achieve.

Allows mixed use of electric and pneumatic feeders in the same feeder base.

Automatic calibration of nozzle height, manpower can be utilized efficiently.

Quality control

We have QC person stay on the production lines do to the inspection.

All products must have been inspected before delivery. We do inline inspection and final inspection.

1. All raw material checked once it arrive our factory.

2. All pieces and logo and all details checked during production.

3. All packing details checked during production.

4. All production quality and packing checked on final inspection after finished.

Package & Shipping

Standard Accessories / Quantity

| Standard Accessories / Quantity | *1 | USB flash drive packaging - full opening window with sponge (87*60*18) | *1 | Pan head cross screws set (5*10) | *5 | PCB Positioning block assembly | *1 |

| Air pipe connector(10-8) | *1 | Double Sided Adhesive Tape (A4) | *2 | Cup head screws (5*14) | *5 | PCB Positioning Block | *9 |

| Air pipe connector(12-8) | *1 | File bag | *1 | M5 flat spacers | *5 | Round magnets (D10*2) | *9 |

| JIEKE Allen wrench Set (BM-C7) | *1 | Female Connector | *2 | M5 elastic spacers | *5 | Feeder solenoid valve (333-C4ZP) | *1 |

| Open end wrench(30) | *1 | Certificate | *1 | Cup head screws (4*16) | *5 | Nozzle | *10pcs |

| Open end wrench(46) | *1 | Warranty Card | *1 | M4 flat spacers | *5 | Demo PCB | *1 |

| Cross screwdriver(6*100) | *1 | User Manual | *1 | M4 elastic spacers | *5 | Mouse and keyboard tray | *1 |

| 8G Flash Drive | *1 | Back zero mark card | *3 | Ties | *4 | Monitor Stand | *1 |

| Power cord | *1 |

About Us

Factory

Zhejiang NeoDen Technology Co., LTD., founded in 2010, is a professional manufacturer specialized in SMT pick and place machine, reflow oven, stencil printing machine, SMT production line and other SMT Products. We have our own R & D team and own factory, taking advantage of our own rich experienced R&D, well trained production, won great reputation from the world wide customers.

We believe that great people and partners make NeoDen a great company and that our commitment to Innovation, Diversity and Sustainability ensures that SMT automation is accessible to every hobbyist on everywhere.

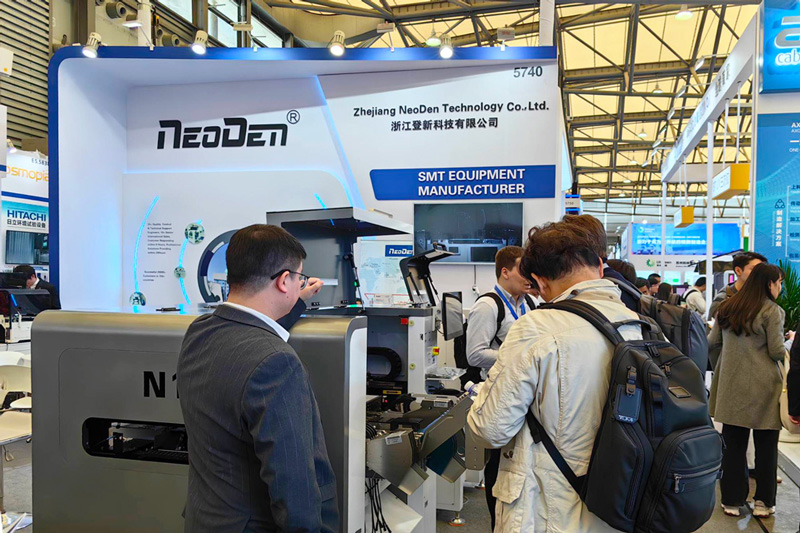

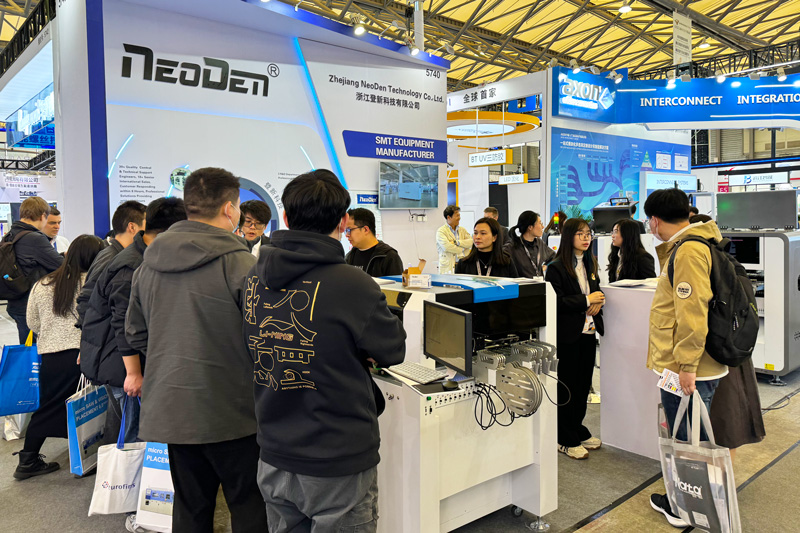

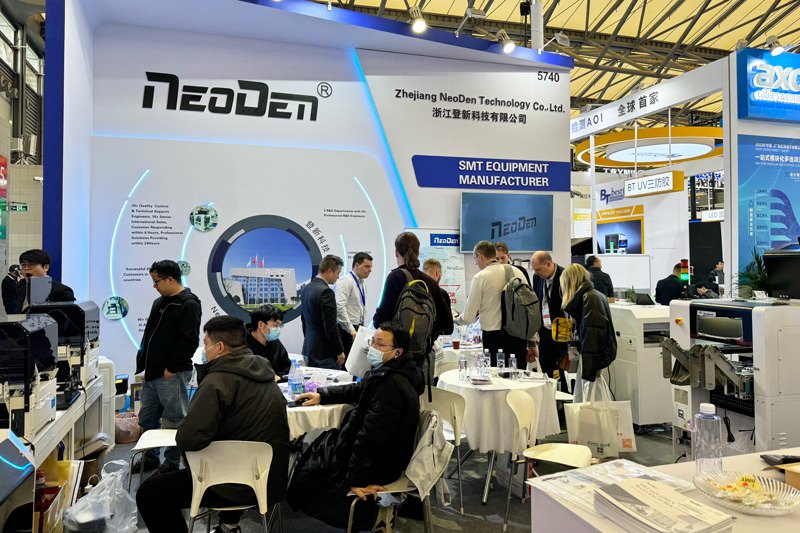

Exhibition

Certification

FAQ

Q1. What’s your after-sale service about NeoDen N10P SMT equipment?

A. NeoDen N10P quality warranty period is 2 years.

Any quality problem will be solved to customer satisfactions.

Q2. How long is NeoDen N10P delivery time?

A. The general delivery time is 10-20 days after receiving your order confirmation.

Anther, if we have the goods in stock, it will only take 1-2 days.

Q3. How do I pay?

A: My friend, there are many ways.

T/T(we prefer this one), Western Union, PayPal, choose your favorite one.

Q4. Is it hard to use these machines?

A: No, not hard at all.

For our previous clients, at most 2 days is enough to learn to operate the machines.

Q5. How about the warranty?

A: We support 2 years warranty.

We will help you in time.

All the spare parts will be provided free of charge for you within the warranty period.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.