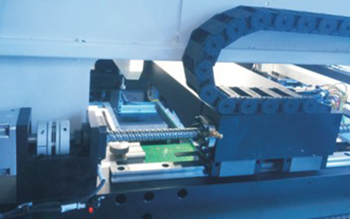

SMT Automatic Printer

SMT Automatic Printer

Specification

| Product name | SMT Automatic Printer |

| Maximum board size(X x Y) | 450mm x 350mm |

| Minimum board size(X x Y) | 50mm x 50mm |

| PCB thickness | 0.4mm~6mm |

| Warpage | ≤1% Diagonal |

| Maximum board weight | 3Kg |

| Board margin gap | Configuration to 3mm |

| Maximum bottom gap | 20mm |

| Transfer speed | 1500mm/s(Max) |

| Transfer height from the ground | 900±40mm |

| Transfer orbit direction | L-R,R-L,L-L,R-R |

| Machine weight | Appro.1000Kg |

Feature

Standard Configuration

1. HTGD Special PCB thickness adaptive system

The platform height is automatically calibrated according to PCB thickness setting, which is intelligent, fast, simple and reliable in structure.

2. Printing axis servo drive

The scraper Y axis adopts servo motor drive through screw drive,to improve accuracy grade,operational stability and extend the service life,to provide customers with a good printing control platform.

Options Configuration

Support MES system seamless docking

It can scan the one-dimensional code or two-dimensional code on the customer PCB and record the relevant information, which can be shared with the customer MES system. MES system uses two-dimensional code, one-dimensional code, mobile IOT and other technologies to conduct scientific management on the warehouse material preparation and prevention, incoming material picking management, material loading and error prevention, production scheduling, quality traceability, Kanban control, etc. in the SMT production process. By optimizing the process, we can improve the production efficiency, product quality, shorten the production cycle, reduce the manufacturing cost, prevent mistakes and stupefaction in an all-round way, realize comprehensive and scientific traceability management, help enterprises respond to market changes quickly, and improve their core competitiveness.

Provide one-stop SMT assembly production line

Related products

About us

Factory

40+ global partners covered in Asia,Europe,America,Oceania and Africa,to successfully serve 10000+ users in all of the world,to ensure the better and faster local service and prompt response.

3 different R&D teams with total 25+ professional R&D engineers,to ensure the better and more advanced developments and new innovation.

Skilled and professional english support&service engineers,to ensure the prompt response within 8 hours,solution provides within 24 hours.

Certification

Exhibition

FAQ

Q1: How many workers in your factory?

A: More than 200 workers.

Q2: How your quality guarantee?

A: We have 100% quality guarantee to customers. We will be responsible for any quality problem.

Q3: What is your advantage compared with your competitors?

A: (1). Qualified Manufacturer

(2). Reliable Quality Control

(3). Competitive Price

(4). High Efficiency working (24*7hours)

(5). One-Stop Service

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.