SMD Reflow Soldering Station

SMD Reflow Soldering Station

Specification

1. Built-in welding smoke filtering system, effective filtration of harmful gases, elegant appearance and eco-friendly, more in line with the high-end use environment.

2. Intelligent, the custom developed intelligent control system, easy to use and powerful.

3. Beautiful and elegant indicator design with red, yellow and green alarm function.

4. The unique heating plate design effectively ensures IN12 will cool down evenly once the heating is stopped, and effectively prevents the deformation and damage caused by the rapid temperature drop.

Feature

Product name: SMD Reflow Soldering Station

Cooling fan: Upper4

Conveyor speed: 50~600 mm/min

Temperature range: Room temperature~300℃

PCB temperature deviation: ±2℃

Max soldering height(mm): 35mm (includes PCB thickness)

Max soldering width (PCB Width): 350mm

Length process chamber: 1354mm

Electricity supply: AC 220v/single phase

Machine size: L2300mm×W650mm×H1280mm

Heat-up time: 30 min

Net weight: 300Kgs

Details

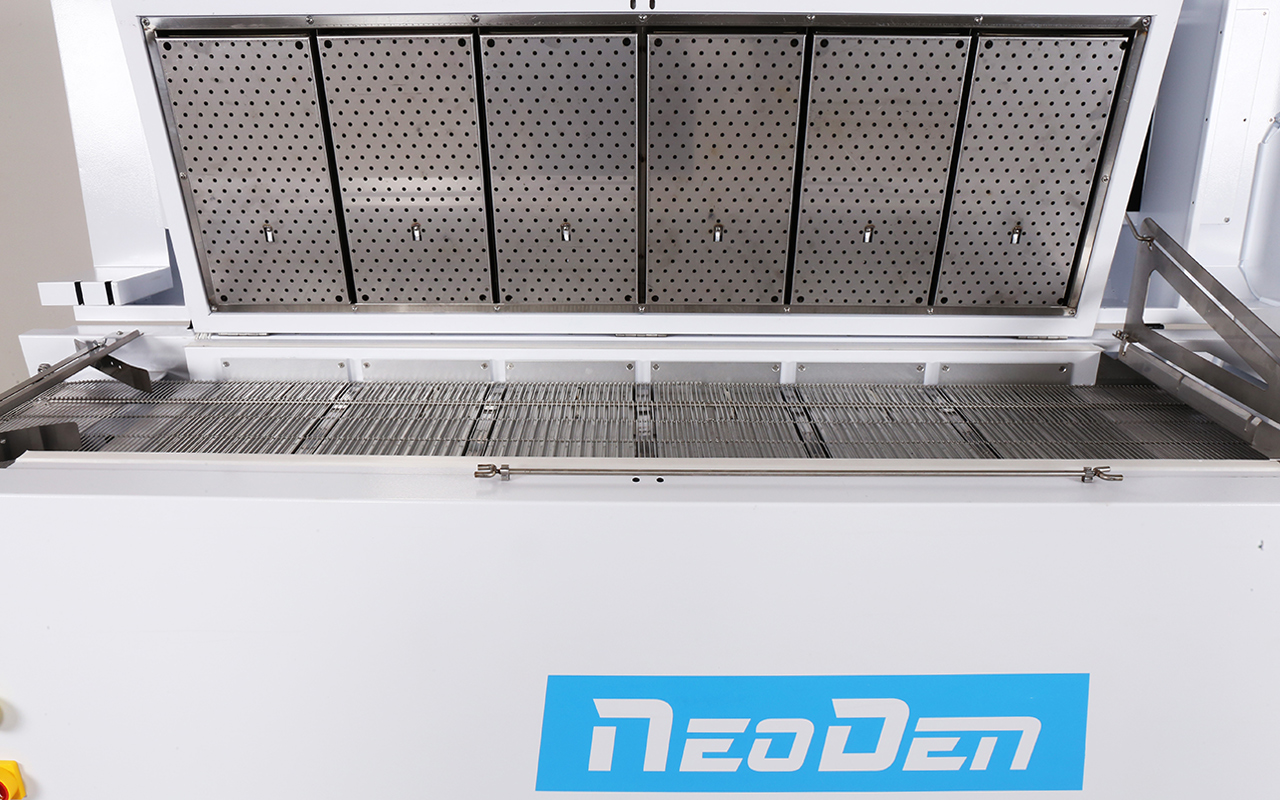

12 temperature zones

High temperature control accuracy

Uniform temperature distribution in the thermal compensation area

Cooling zone

Independent circulating air design

Isolates the influence of the external environment

Energy saving & Eco-friendly

Welding smoke filtering system

low power consumption, low power supply requirements

Operation panel

Hidden screen design

convenient for transportation

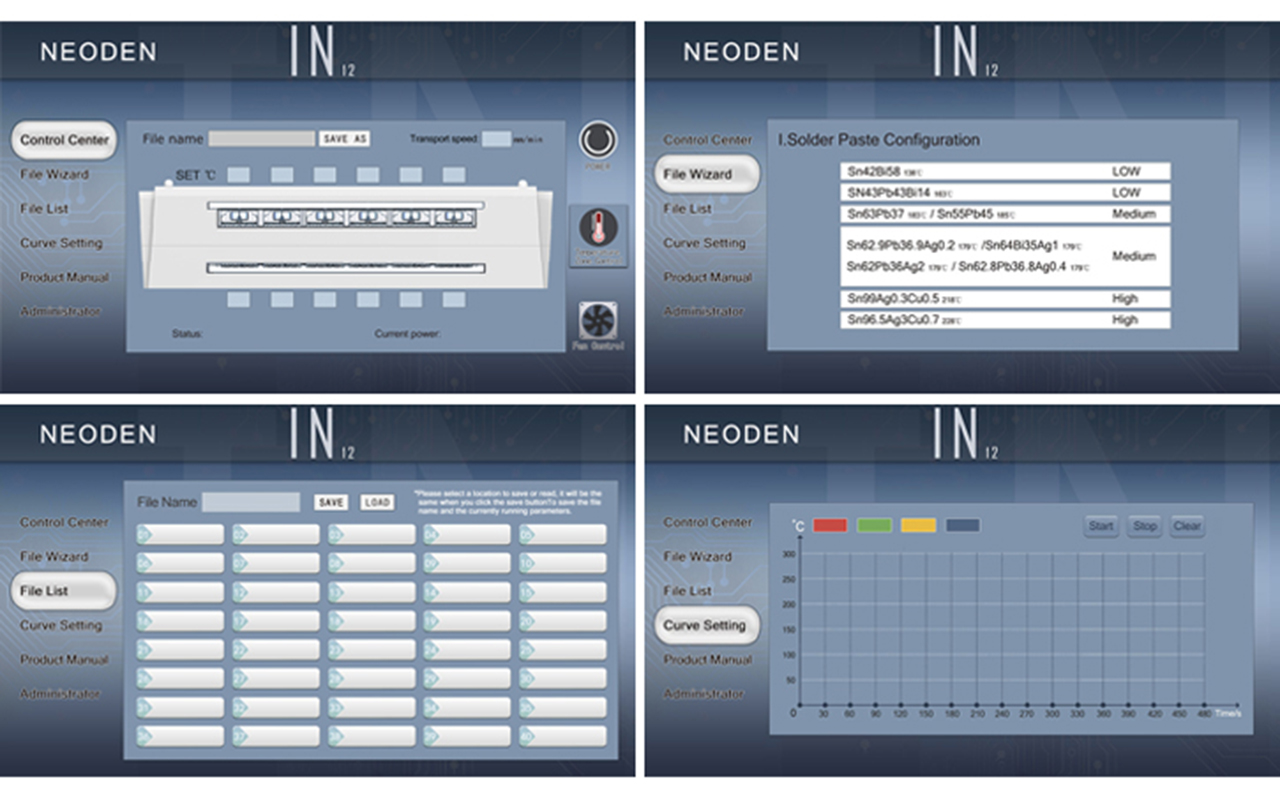

Intelligent control system

Custom developed intelligent control system

Temperature curve can be displayed

Elegant appearance

In line with high-end use environment

Lightweight, miniaturization, professional

What is PCB surface temperature?

The temperature of component soldering feet when PCB is soldered.

(the guide temperature on the soldering wave provided by the solder paste manufacturer refers to the PCB surface temperature.)

When working, the temperature displayed in the temperature zone on the panel is the actual temperature of the heating unit, which does not represent the temperature in the oven and the actual temperature of the plate surface.

Therefore, the temperature displayed will be about 20-40 degrees higher than the temperature in the oven. The actual use is related to the chain speed, PCB size, thickness, material and component density.

FAQ

Q1: This is the first time I use this kind of machine, is it easy to operate ?

A: We have English user manual and guide video to teach you how to use the machine . If still have question , pls contact us by email / skype / whatapp / phone / trademanager online service.

Q2: Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT Machine, Pick and Place Machine, Reflow Oven, Screen Printer, SMT Production Line and other SMT Products.

Q3: What is your advantage compared with your competitors?

A: (1). Qualified Manufacturer

(2). Reliable Quality Control

(3). Competitive Price

(4). High Efficiency working (24*7hours)

(5). One-Stop Service

About us

Factory

Zhejiang NeoDen Technology Co., Ltd. has been manufacturing and exporting various small pick and place machines since 2010. Taking advantage of our own rich experienced R&D, well trained production, NeoDen wins great reputation from the world wide customers.

① Established in 2010, 200+ employees, 8000+ Sq.m. factory

② 30+ Global Agents covered in Asia, Europe, America, Oceania and Africa

③ R&D Center: 3 R&D departments with 25+ professional R&D engineers

Exhibition

Certification

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.