SMD pick and place vision|SMT machine

SMD pick and place vision|SMT machine Video

NeoDen4 SMD pick and place vision|SMT machine

Specifications

| Product name | NeoDen4 SMD pick and place vision|SMT machine |

| Machine Style | Single gantry with 4 Heads |

| Placement Rate | 4000CPH |

| External Dimension | L 680×W 870×H 460mm |

| Max applicable PCB | 290mm*1200mm |

| Feeders | 48pcs |

| Average working power | 220V/160W |

| Component Range | Smallest Size: 0201 |

| Biggest Size: TQFP240 | |

| Max Height: 5mm |

Details

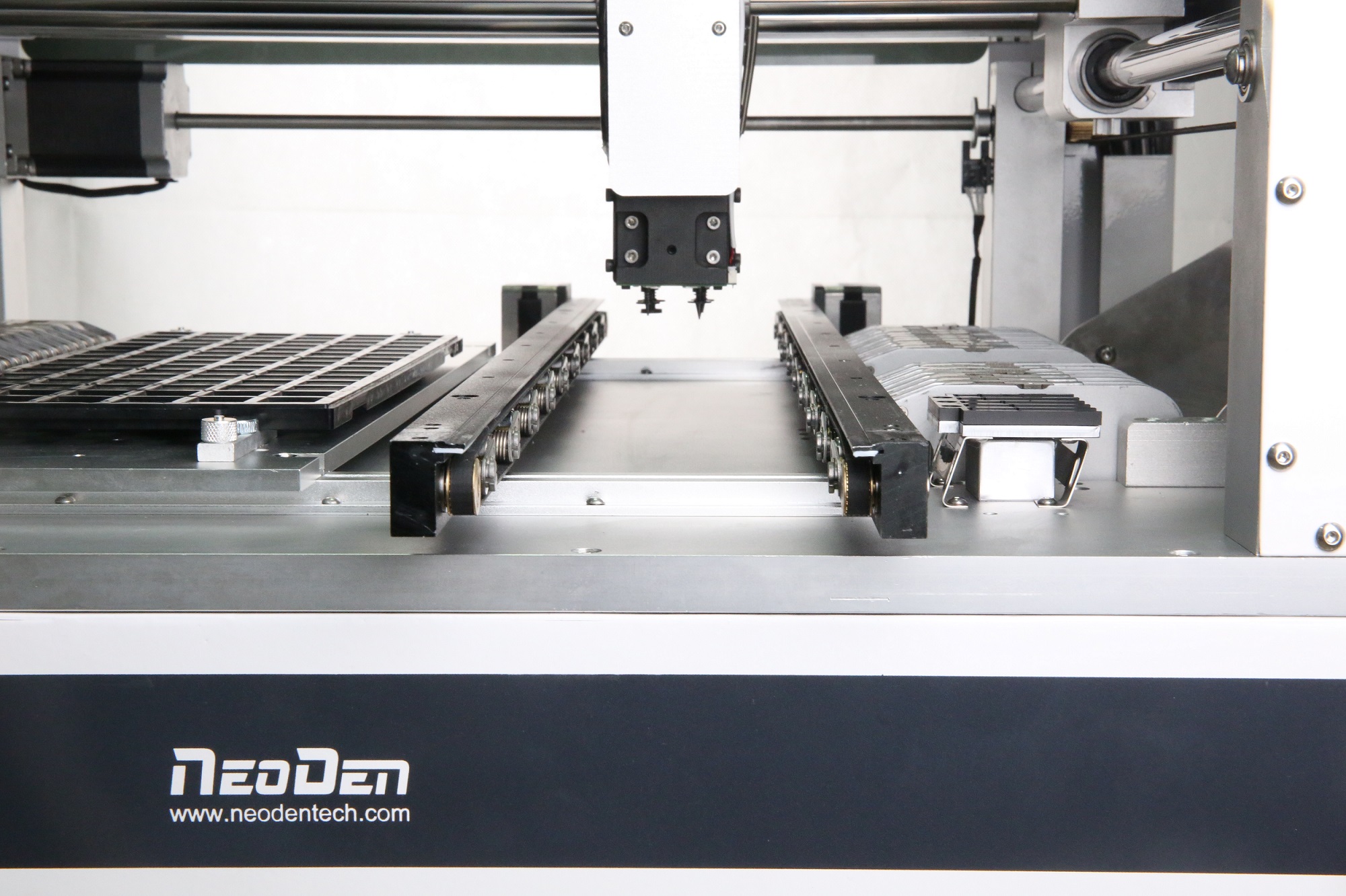

On-line dual rails

Support both seamless mounting via automatic rails and PCB self-positioning mounting, can be extended a vibrating plate to support bulk components, achieve best mounting without bother.

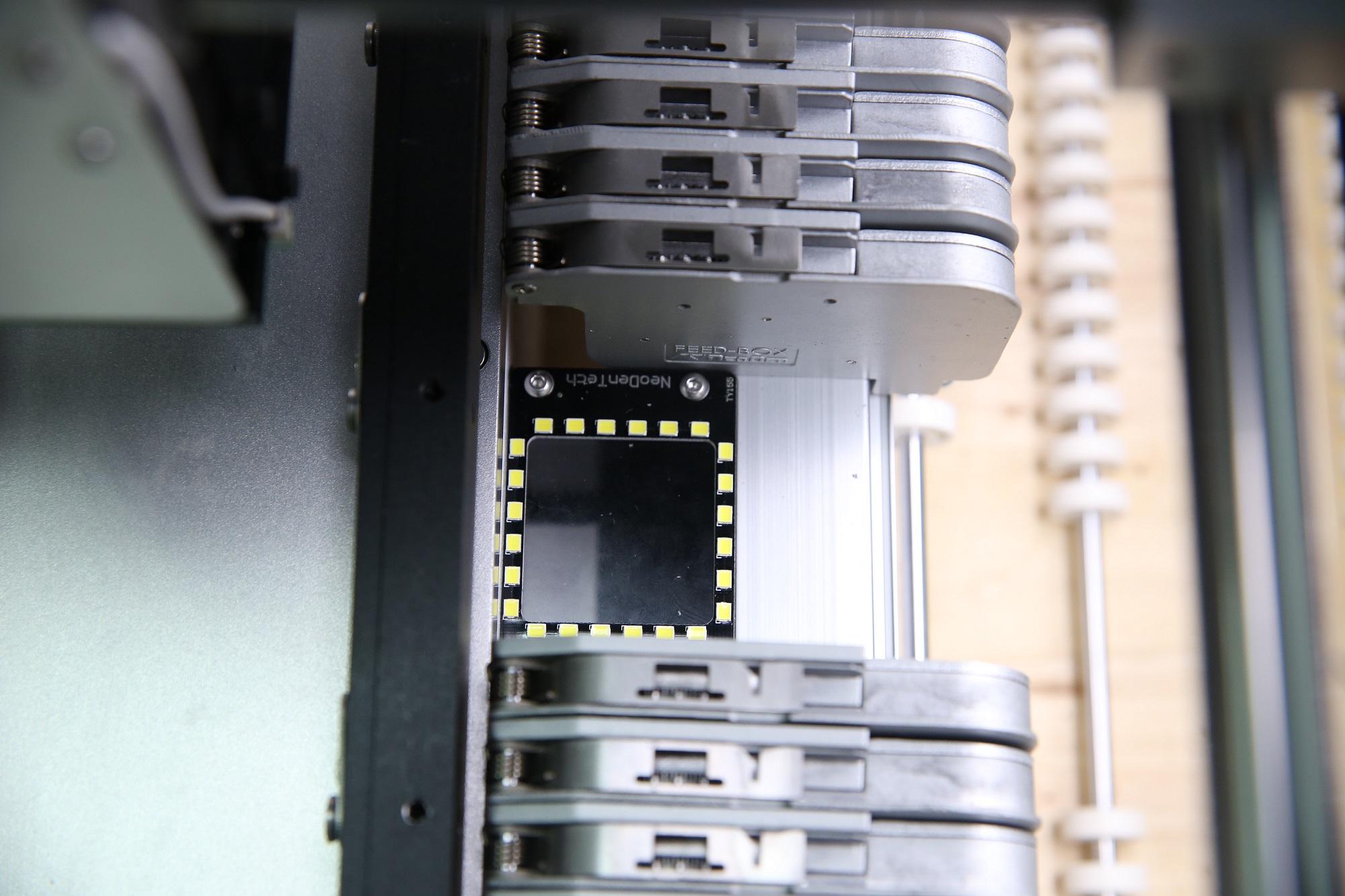

Vision system

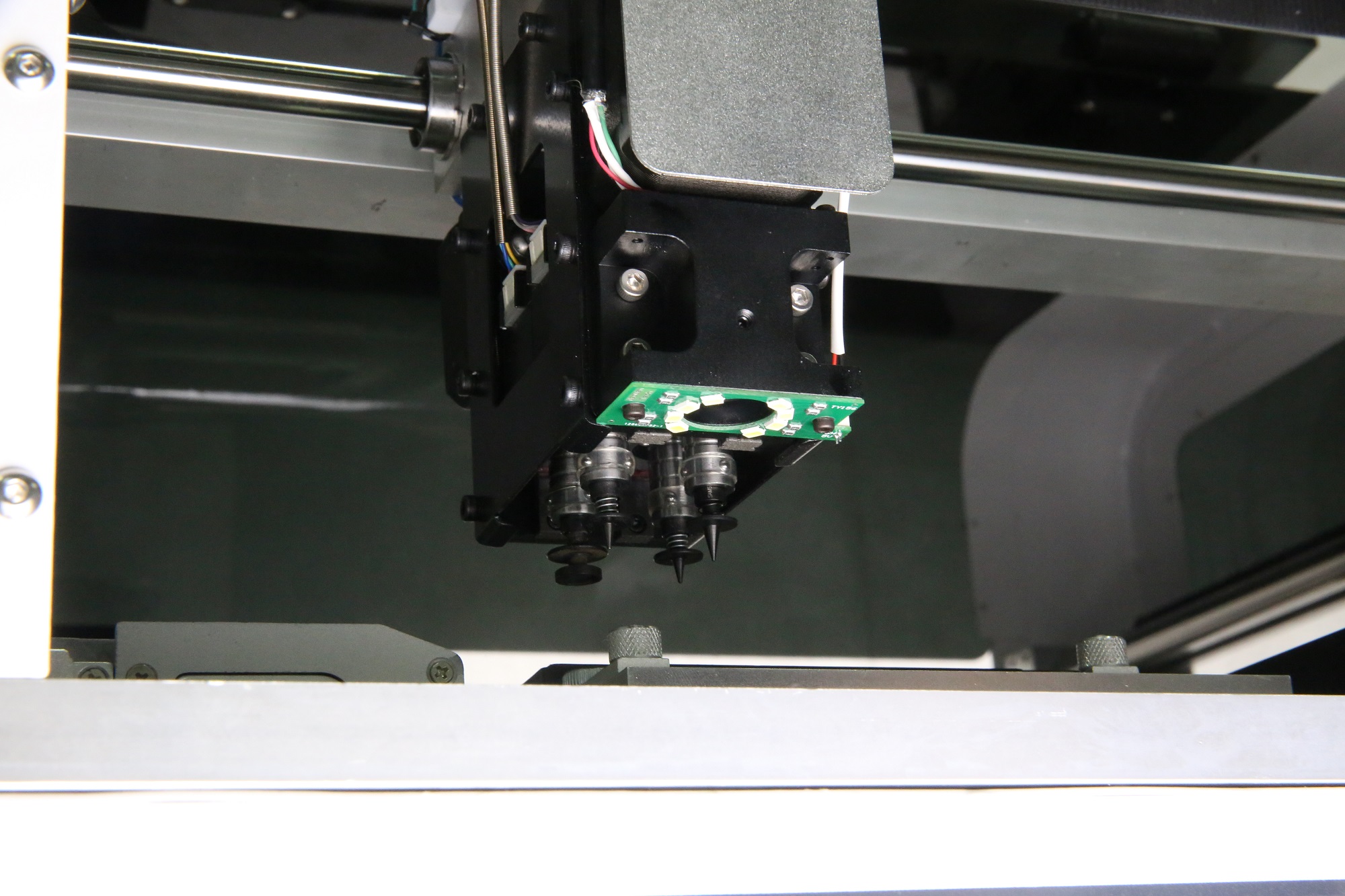

Four high precision nozzles

The mounting head is designed in a suspended, fully symmetric and high degree of coupling way, ensure it can mount components with higher space, more gentle and more efficient.

Electric tape-and-reel feeders

Packing

Caution

1. When an exception or failure happens, or power failure, please terminate the operation of Windows, and power it off.

2. Power off prior to cleaning and repairing in case of any accidents.

3. When pull the plug, please hold the head instead of wire.

Provide one-stop SMT assembly production line

Related products

If you need, please feel free to contact us.

FAQ

Q1: Do you provide software updates?

A: Customers who buy our machine,we can offer free upgrades software for you .

Q2: How about the warranty?

A: We have 2 years warranty for NeoDen4 , 1 year for all other model , life time after-sales support.

Q3: What products you sell?

A: Our company deal in the following products:

SMT equipment

SMT accessories: Feeders, Feeder parts

SMT nozzles, nozzle cleaning machine, nozzle filter

About us

Exhibition

Certificates

Factory

If you need, please feel free to contact us.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.