Small desktop pick and place machine

NeoDen4 Small desktop pick and place machine Video

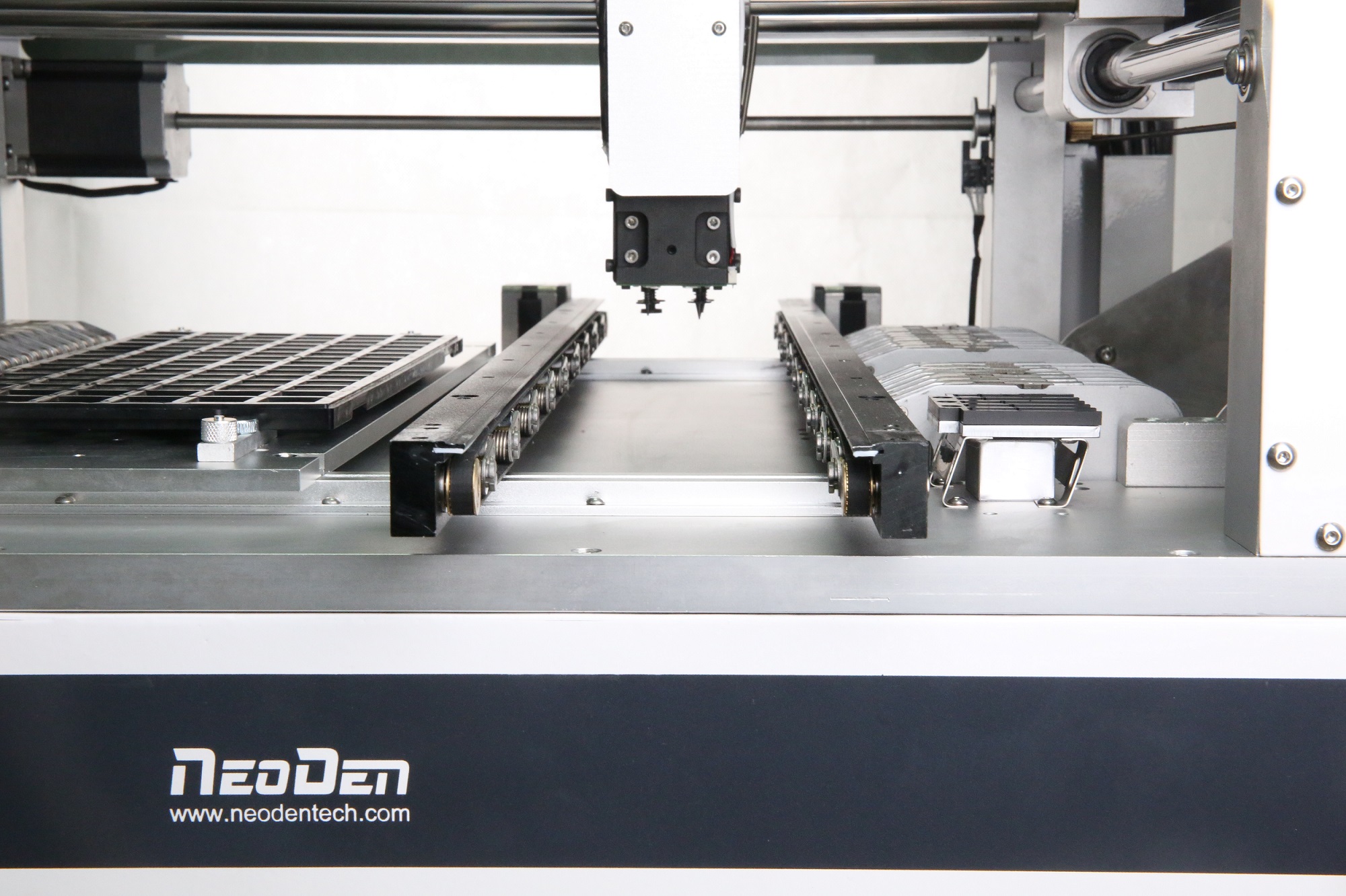

NeoDen4 Small desktop pick and place machine

Specifications

| Product name | NeoDen4 Small desktop pick and place machine |

| Machine Style | Single gantry with 4 Heads |

| Placement Rate | 4000CPH |

| External Dimension | L 680×W 870×H 460mm |

| Max applicable PCB | 290mm*1200mm |

| Feeders | 48pcs |

| Average working power | 220V/160W |

| Component Range | Smallest Size: 0201 |

| Biggest Size: TQFP240 | |

| Max Height: 5mm |

Details

On-line dual rails

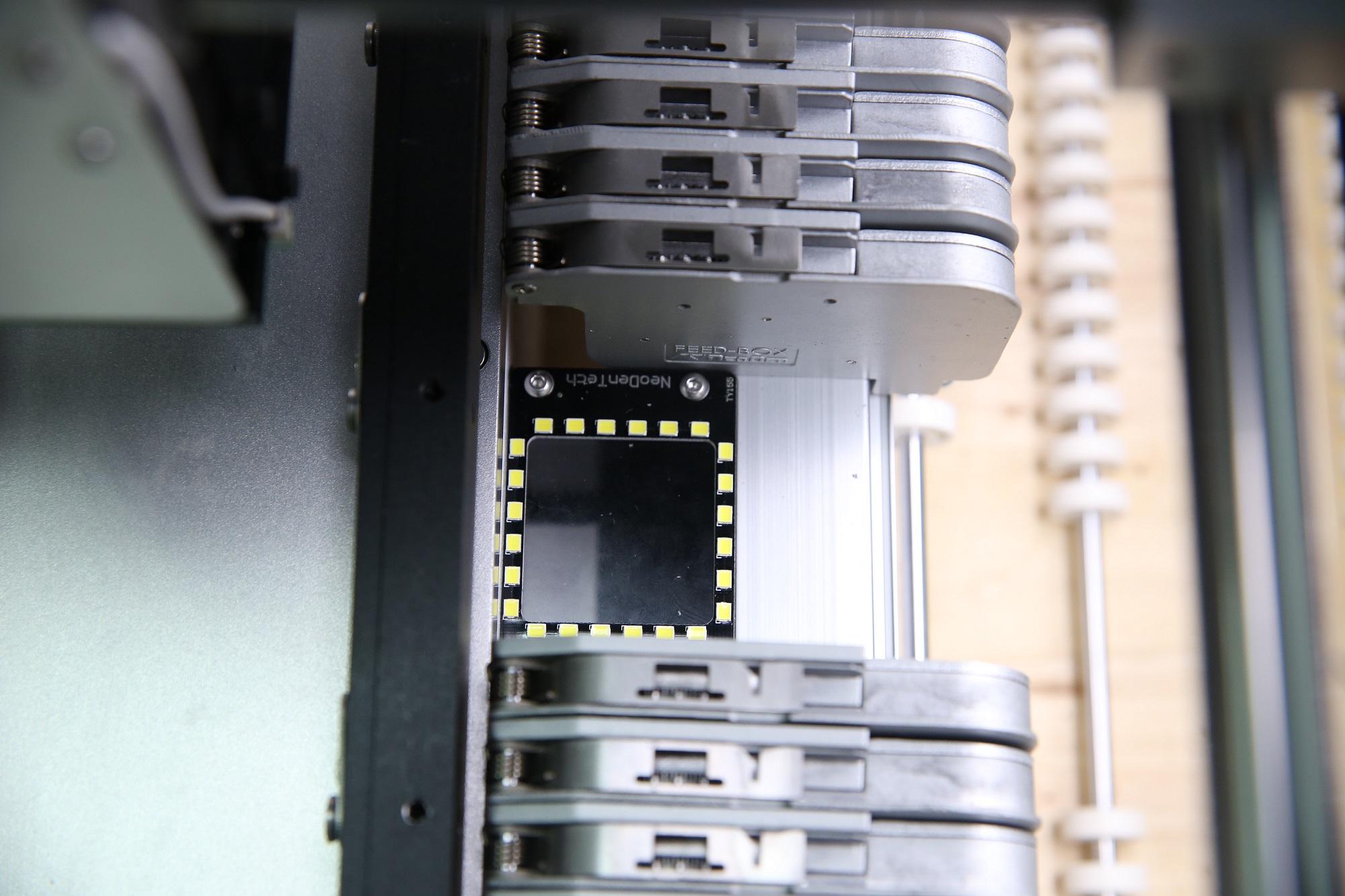

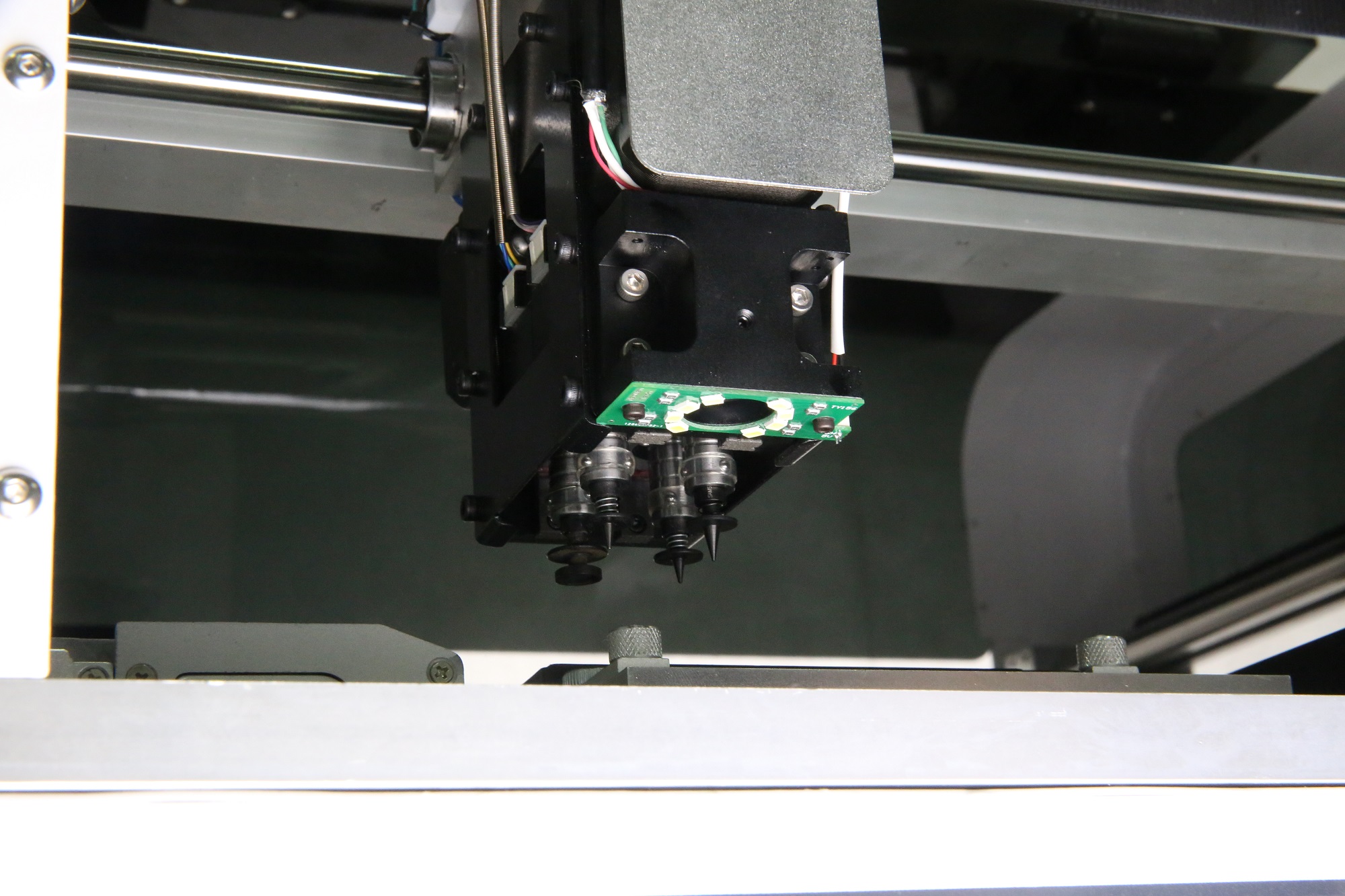

Vision system

The NeoDen4 features a high-precision, two-camera vision system. The cameras are made by Micron Technology and are precisely aligned to the nozzles using the single unified configuration/operation application that loads on power-on.

Four high precision nozzles

Electric tape-and-reel feeders

Packing

Caution

Provide one-stop SMT assembly production line

Related products

If you need, please feel free to contact us.

FAQ

Q1: Do you provide software updates?

A: Customers who buy our machine,we can offer free upgrades software for you .

Q2: Can we customize the machine?

A: Of course. All of our machines can be customized.

Q3: How about the warranty?

A: We support one year warranty. We will help you in time. All the spare parts will be provided free of charge for you within the warranty period.

About us

Exhibition

Certificates

Factory

If you need, please feel free to contact us.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.