Reflow oven NeoDen IN12

Reflow oven NeoDen12

Description

Features

1. The control system has features of high integration, timely response, low failure rate and convenient maintenance.

2. The unique design of heating module has the characteristics of high temperature control accuracy, uniform temperature distribution in the thermal compensation area, high thermal compensation efficiency and low power consumption.

3. Hot air convection, excellent soldering performance.

4. High-performance aluminum alloy heating plate instead of heating pipe, both energy-saving and high-efficient, and transverse temperature deviation is significantly reduced compare to the similar reflow oven products in the market.

5. Heat insulation protection design, the casing temperature can be effectively controlled.

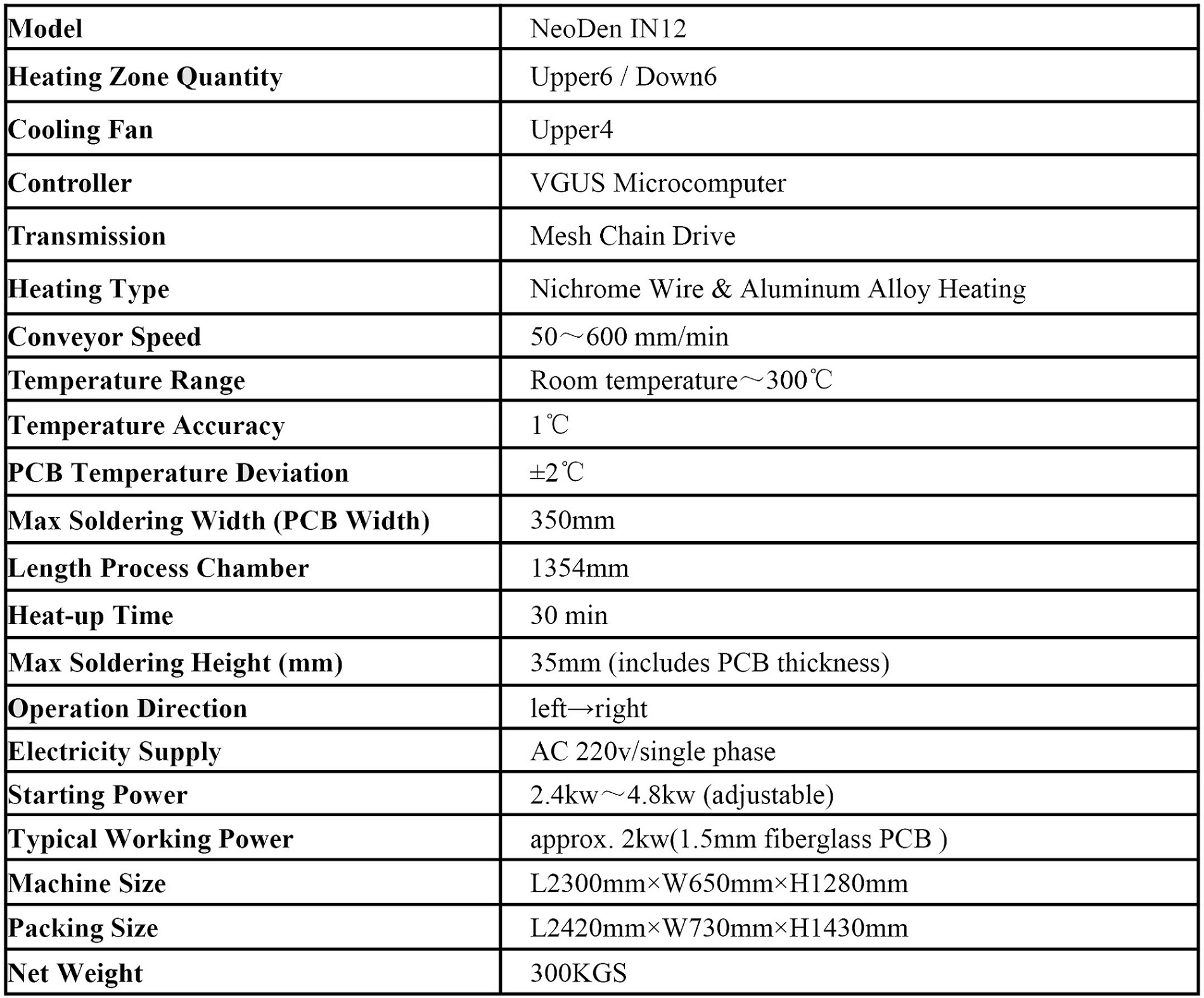

Specification

Details

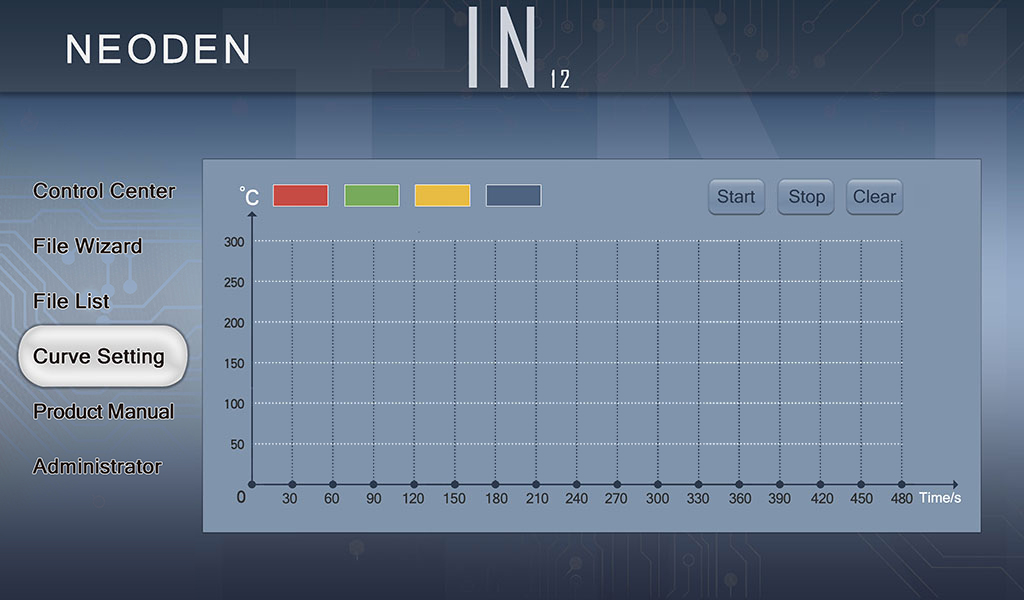

Real-time measurement

1-PCB soldering temperature curve can be displayed based on real-time measurement.

2-Professional and unique 4-way board surface temperature monitoring system, can give timely and comprehensive data feedback in actual operation.

3-40 working files can be stored for an easy loading during the working process.

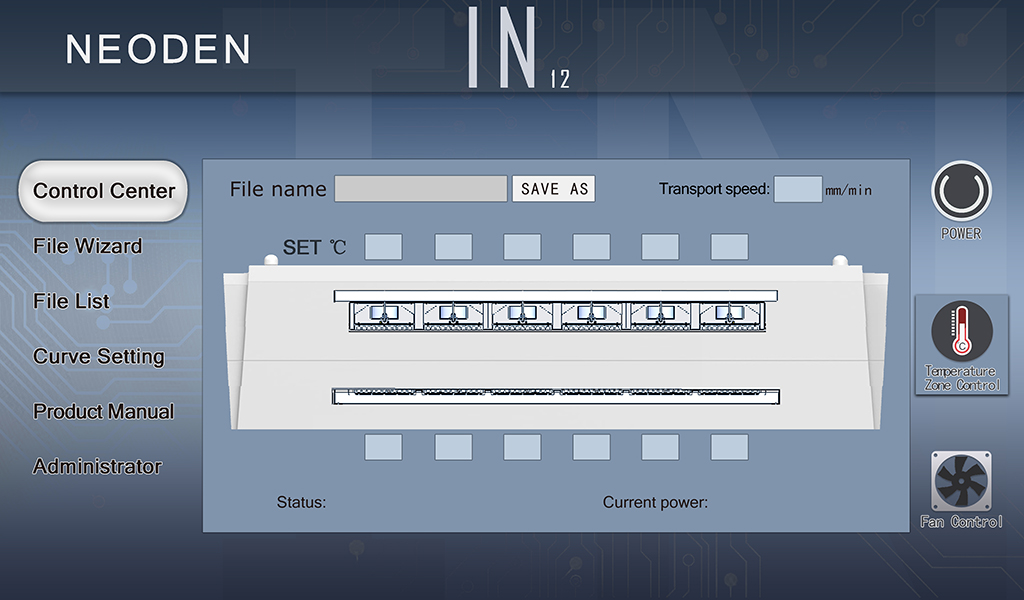

Intelligent control system

1-Heat insulation protection design, the casing temperature can be effectively controlled.

2- Smart control with high sensitivity temperature sensor, the temperature can be effectively stabilized.

3-Intelligent, the custom developed intelligent control system, easy to use and powerful.

Energy saving & Eco-friendly

1-Built-in welding smoke filtering system, effective filtration of harmful gases.

2-Energy saving, low power consumption, low power supply requirements, the ordinary civil electricity can meet the use.

3-The internal thermostat is made of stainless steel, which is environment friendly and has no peculiar smell.

Attentive design

1-Hidden screen design is convenient for transportation, easy to use.

2-The upper temperature cover is automatically limited once opened, effectively ensuring the personal safety for the operators.

Provide one-stop SMT assembly production line

Related products

FAQ

Q1: How can I buy machine from you?

A: (1) Consult us on line or by e-mail.

(2) Negotiate and confirm the final price, shipping , payment method and other terms.

(3) Send you the perfroma invoice and confirm your order.

(4) Make the payment according to the method put on proforma nvoice.

(5) We prepare your order in terms of the proforma invoice after confirming your full payment. And 100% quality check before shipping.

(6) Send your order via express or by air or by sea.

Q2: What products you sell?

A: Our company deal in the following products:

SMT equipment

SMT accessories: Feeders, Feeder parts

SMT nozzles, nozzle cleaning machine, nozzle filter

Q3: MOQ?

A: 1 set machine, mixed order is also welcomed.

About us

Certification

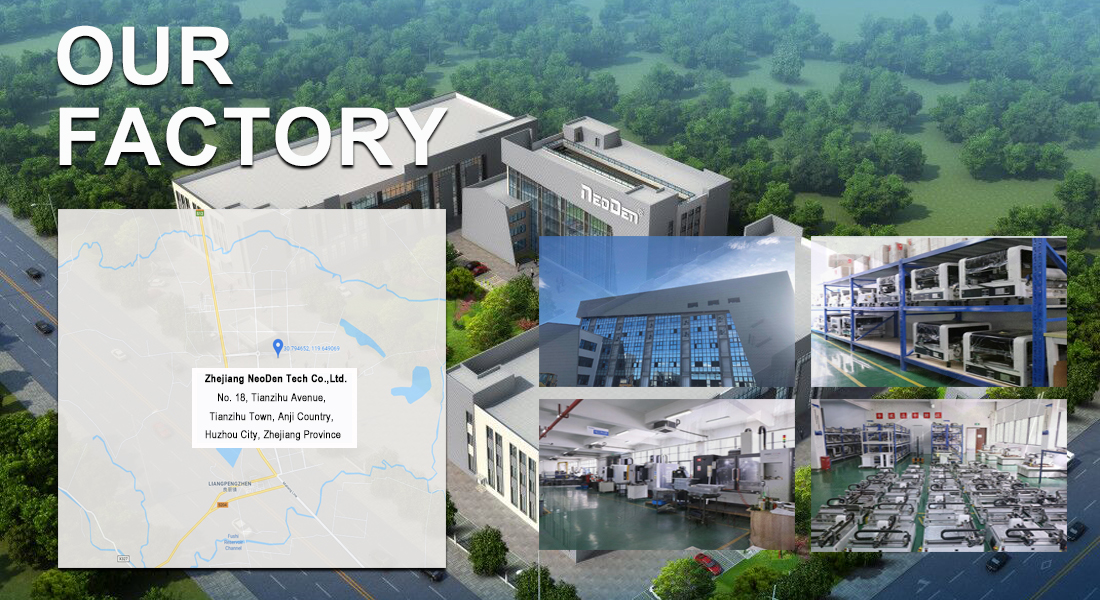

Factory

NeoDen provides a full SMT assembly line solutions, including SMT reflow oven, wave soldering machine, pick and place machine, solder paste printer, PCB loader, PCB unloader, chip mounter, SMT AOI machine, SMT SPI machine, SMT X-Ray machine, SMT assembly line equipment, PCB production Equipment SMT spare parts, etc any kind SMT machines you may need, please feel free to contact us.

Hangzhou NeoDen Technology Co., Ltd

Web: www.smtneoden.com

Email: info@neodentech.com

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.