Reflow Oven Manufacturer

Reflow Oven Manufacturer

Specification

| Product name | Reflow Oven Manufacturer |

| Model | NeoDen IN12C |

| Heating Zone Quantity | Upper6 / Down6 |

| Cooling Fan | Upper4 |

| Conveyor Speed | 50~600 mm/min |

| Temperature Range | Room temperature~300℃ |

| Temperature Accuracy | 1℃ |

| PCB Temperature Deviation | ±2℃ |

| Max soldering height (mm) | 35mm (includes PCB thickness) |

| Max Soldering Width (PCB Width) | 350mm |

| Length Process Chamber | 1354mm |

| Electricity Supply | AC 220v/single phase |

| Machine Size | L2305mm×W612mm×H1230mm |

| Heat-up Time | 30 min |

| Net Weight | 300Kgs |

Details

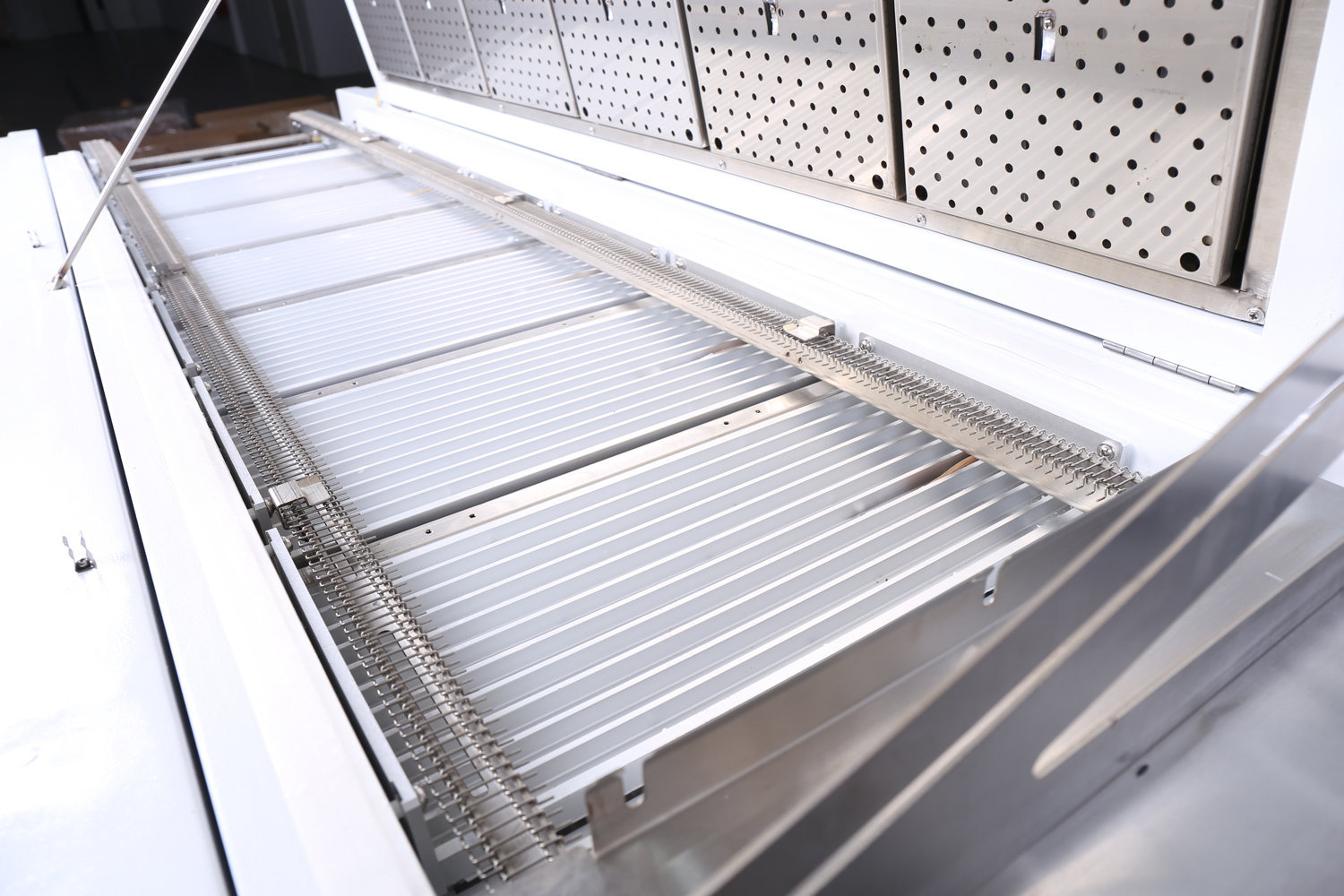

12 Heating Zones

Uniform temperature

High temperature control accuracy

Cooling zone

Independent circulating air design

Isolates the influence of the external environment

Energy saving & Eco-friendly

Welding smoke filtering system

low power and supply requirements

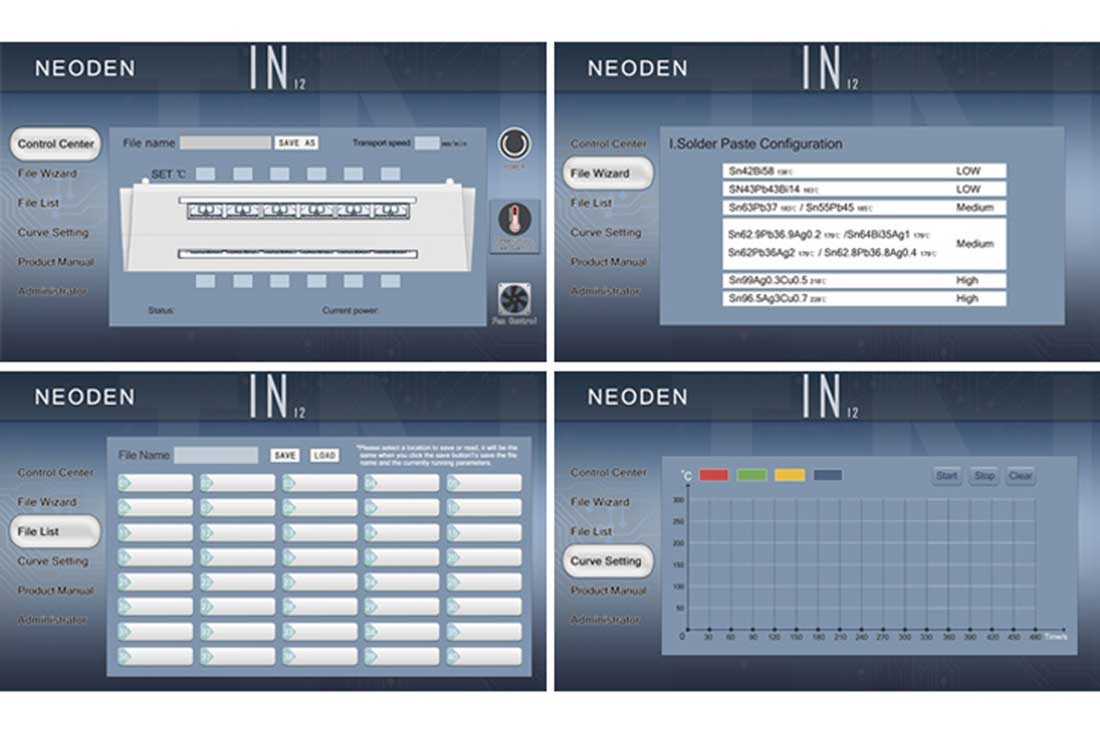

Operation panel

Hidden screen design

Convenient for transportation

Intelligent control system

Custom developed intelligent control system

Temperature curve can be displayed

Elegant appearance

In line with high-end use environment

Lightweight, miniaturization, professional

Features

1. Unique heating module design, with high precision temperature control, uniform temperature distribution in the thermal compensation area, high efficiency of thermal compensation, low power consumption and other characteristics.

2. Hot air convection, excellent welding performance.

3. Energy saving, low power consumption, low power supply requirements, ordinary civilian electricity can meet the use, compared to similar products a year can save electricity costs and then buy 1 unit of this product.

4. Custom-developed track drive motor according to the characteristics of the B-type mesh belt, to ensure uniform speed and long life.

5. Independent circulating air design of the cooling area, completely isolated from the external environment on the internal temperature cavity.

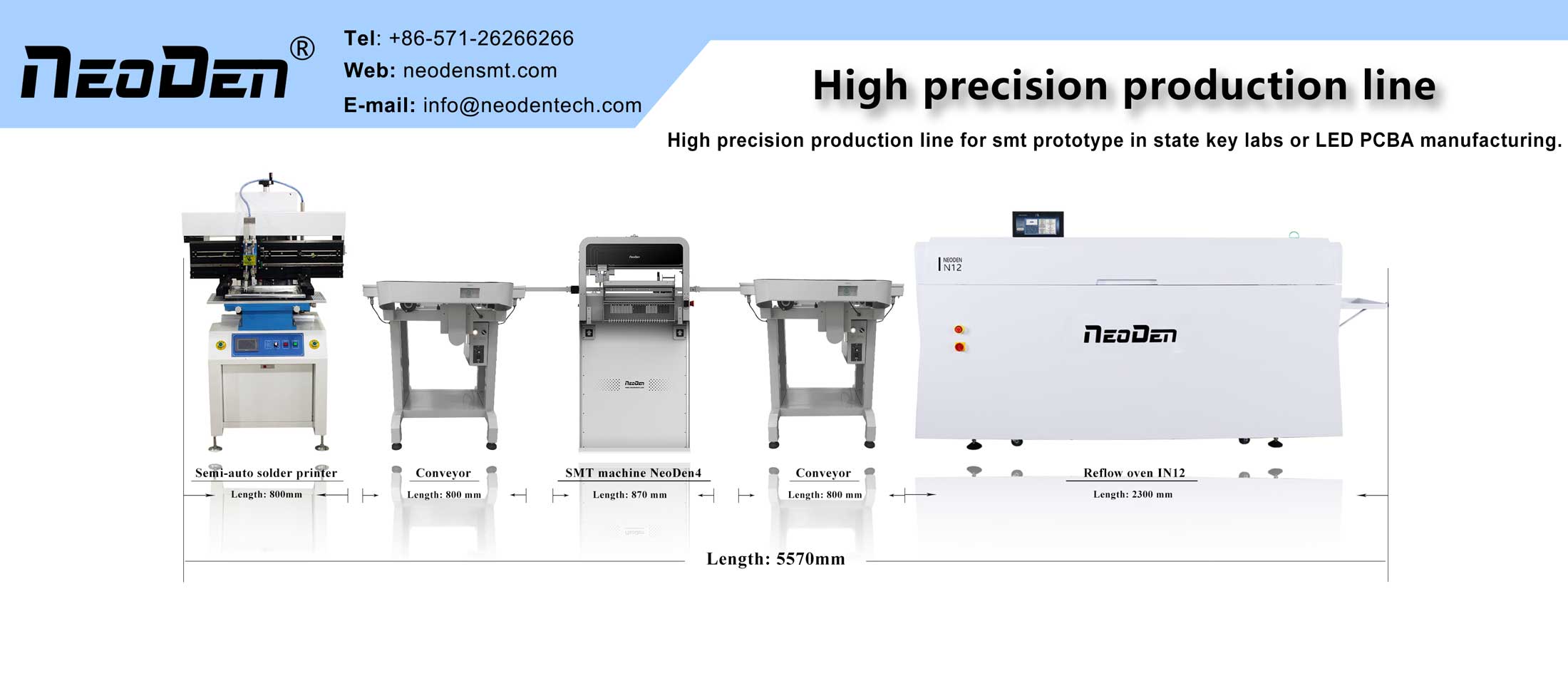

Provide one-stop SMT assembly production line

Related products

FAQ

Q1: What’s your MOQ?

A: Most of our products MOQ is 1 set.

Q2: How long is your delivery time?

A: The general delivery time is 15-30 days after receiving your order confirmation.

Anther, if we have the goods in stock, it will only take 1-2 days.

Q3: When can I get the quotation?

A: We usually quote within 8 hours after we get your inquiry.

If you are very urgent to get the price, please tell us so that we will regard your inquiry priority.

Q4: What is your terms of delivery?

A: EXW, FOB, CIF, etc.

About us

Factory

Quick facts about NeoDen

① Established in 2010, 200+ employees, 8000+ Sq.m. factory

② NeoDen products: Smart series PNP machine, NeoDen K1830, NeoDen4, NeoDen3V, NeoDen7, NeoDen6, TM220A, TM240A, TM245P, reflow oven IN6, IN12, Solder paste printer FP2636, PM3040

③ Successful 10000+ customers across the globe

④ 30+ Global Agents covered in Asia, Europe, America, Oceania and Africa

⑤ R&D Center: 3 R&D departments with 25+ professional R&D engineers

⑥ Listed with CE and got 50+ patents

⑦ 30+ quality control and technical support engineers, 15+ senior international sales, timely customer responding within 8 hours, professional solutions providing within 24 hours

Exhibition

Certification

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.