Pick and Placement Machine

Pick and Placement Machine

Description

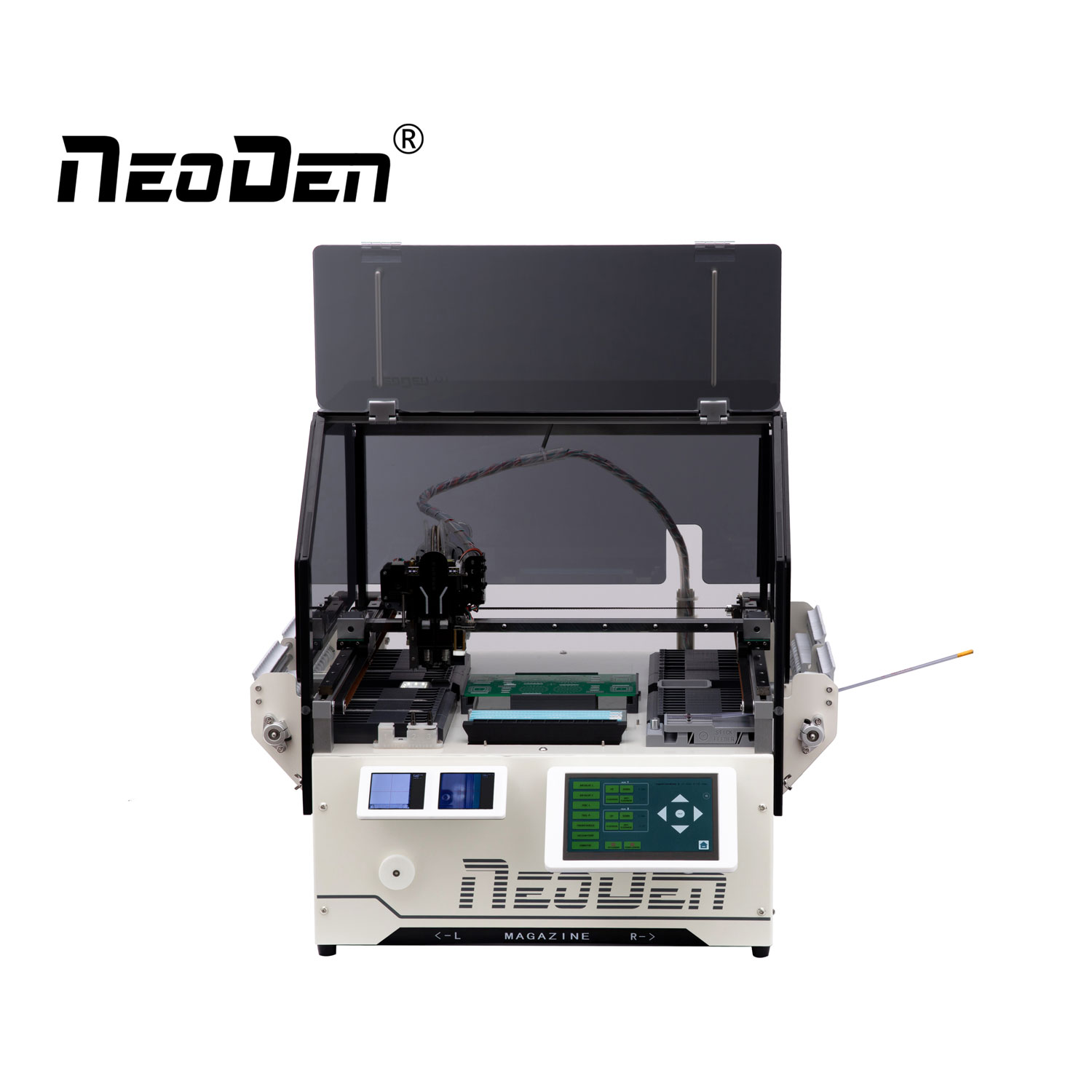

Product name: Pick and Placement Machine

Machine Style: Single Gantry with 2 Heads

Alignment: Vision & Vacuum

Placement Rate: Vision On: 3,000CPH; Vision Off: 4,000CPH

Feeder Capacity: Tape Feeder: 52 (all 8mm); Stick Feeder: 4; Flexible Feeder: 28; Bulk Feeder: 19

Component Range: Smallest Size: 0201; Largest Size: 18x18mm; Max Height: 12mm

External Dimensions(mm): Machine Size: 643(L)x554(W)x601(H); Packing Size: 700(L)x610(W)x595(H) (wooden box)

Product Detail

Vacuum detection

Can set standard vacuum detection values on placement head flexibly,

all information can be displayed visually on the placement head.

Auto nozzle changer

It has 3 slots for nozzles replacement,

which realizes maximum optimum of nozzles and achieve higher continuity of production.

Dual vision system with built-in IC

Independent high-definition & high-speed dual vision recognition systems,

the speed of processing components’ photos becomes more efficient and accurate.

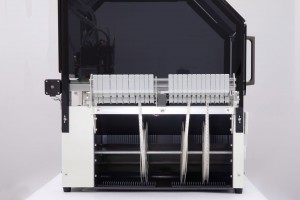

Powerful magazines

Easy to install and replace tape reels conveniently,

ensure the most excellence solution among all of the entry level machines with lower budget but higher stability.

User friendly touch screen

High-definition capacitive touch screen,

adjusted up and down to meet the needs of different viewing angles and enhance the user experiences.

Brand new patented peeling gadget

It’s simple but functional, it’s easy to install and flexible to remove.

Compared with the peelers of TM240A, it doesn’t need to collect wasted film.

Quality control

We have QC person stay on the production lines do to the inspection.

All products must have been inspected before delivery.

We do inline inspection and final inspection.

1. All raw material checked once it arrive our factory.

2. All pieces and logo and all details checked during production.

3. All packing details checked during production.

4. All production quality and packing checked on final inspection after finished.

About us

Factory

Hangzhou NeoDen Technology Co., LTD., founded in 2010, is a professional manufacturer specialized in SMT pick and place machine, reflow oven, stencil printing machine, SMT production line and other SMT Products.

In our global Ecosystem, we collaborate with our best partner to deliver a more closing sales service, high professional and efficient technical support.

Established in 2010 with 100+ employees & 8000+ Sq.m. factory of independent property rights, to ensure the standard management and achieve the most economic effects as well as saving the cost.

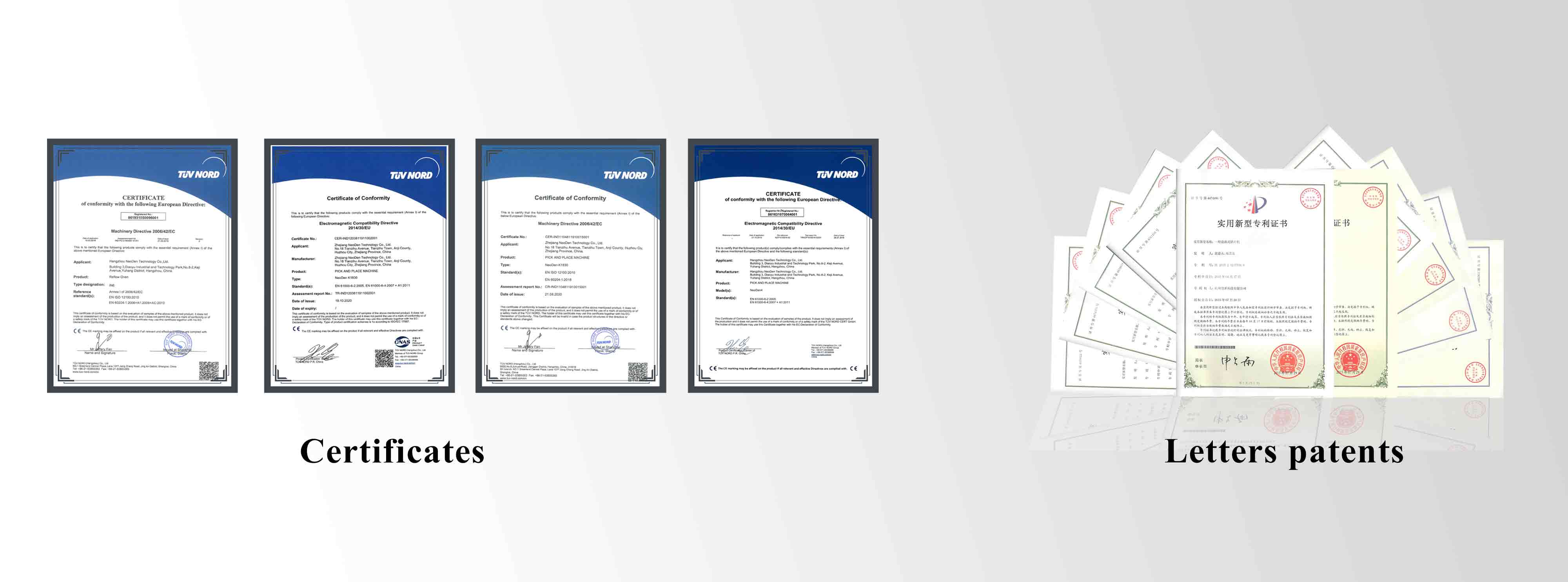

The unique one among all of the Chinese manufacturers who registered and approved CE by TUV NORD.

Certification

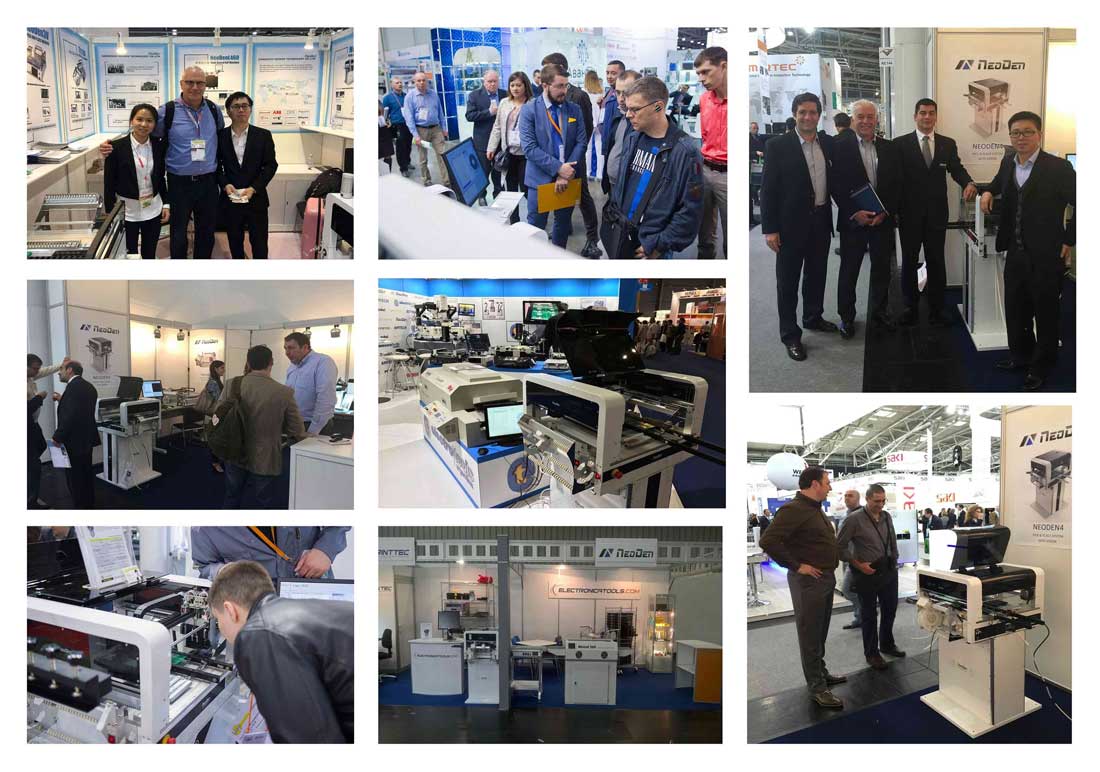

Exhibition

If you need, please feel free to contact us for more information.

FAQ

Q1: What’s is your shipping service?

A: We can provide services for vessel booking, goods consolidation, customs declaration, shipping documents preparation and delivery bulk at the shipping port.

Q2: How far is your factory from the airport and train station?

A: From airport about 2 hours by car, and from train station about 30 minutes.

We can pick up you.

Q3: Can l visit your factory?

A:By all means, we warmly welcome your arrival.

Before you take off from your country, please let us know.

We will show you the way and arrange time to pick you up if possible.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.