Pick and Place PCB Machine NeoDen4

Pick and Place PCB Machine NeoDen4

The fourth-generation model

Description

Specification

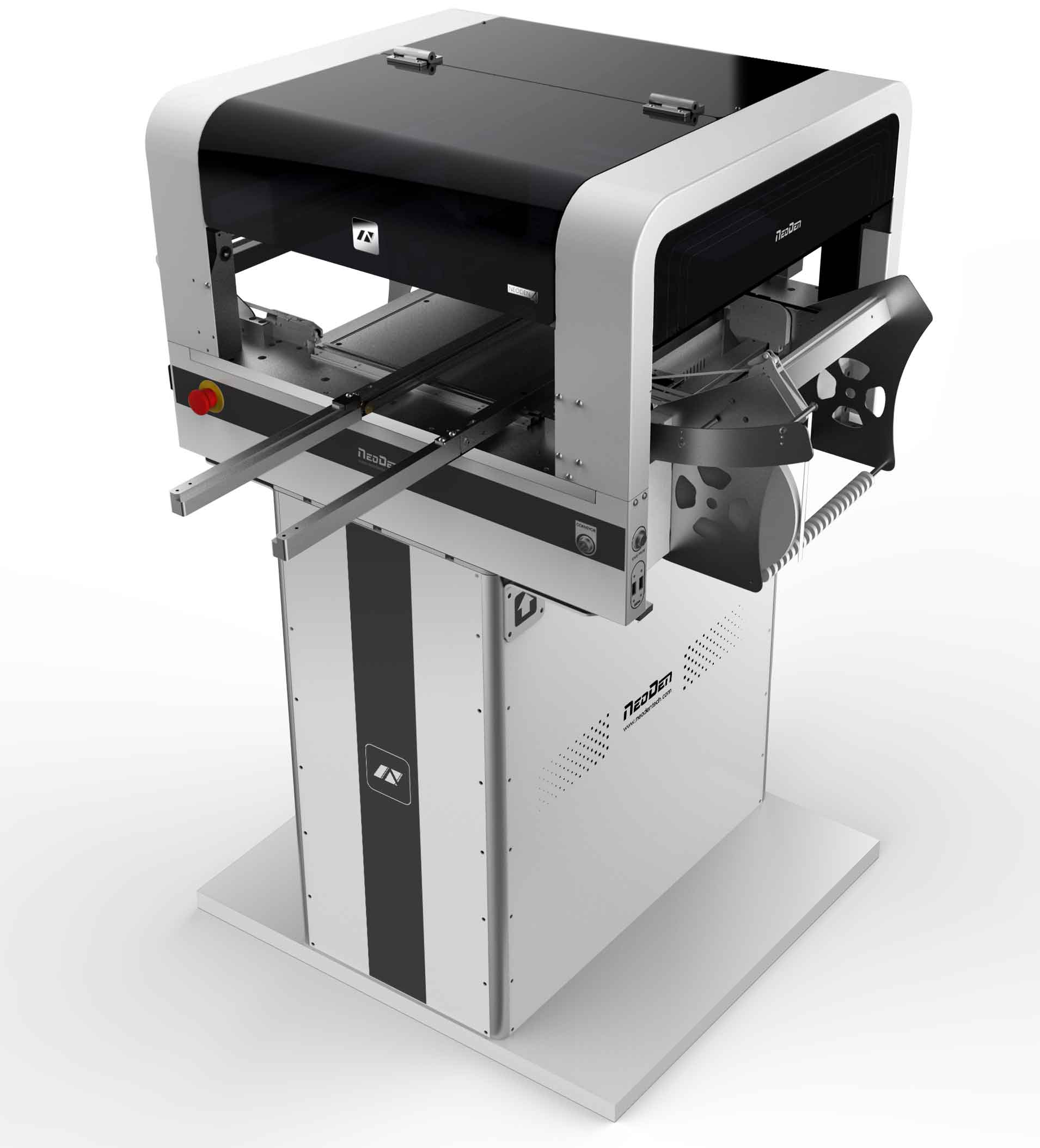

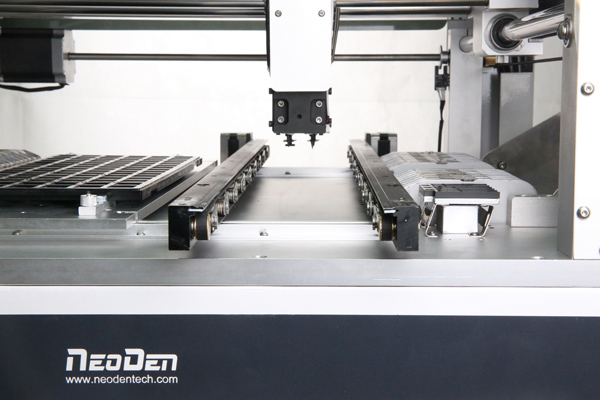

Product name: Pick and Place PCB Machine NeoDen4

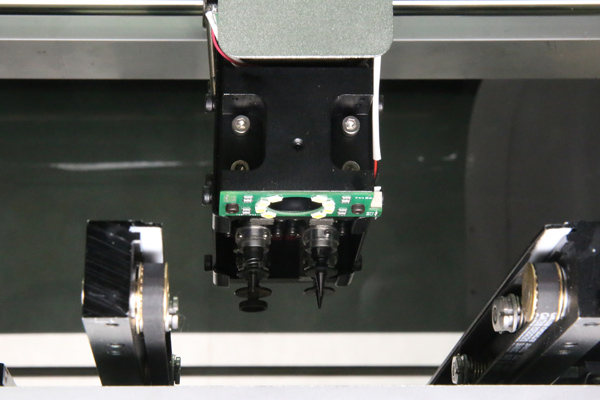

Machine Style: Single gantry with 4 heads

Placement Rate: 4000 CPH

External Dimension: L 870×W 680×H 480mm

Max applicable PCB: 290mm*1200mm

Feeders: 48pcs

Average working power: 220V/160W

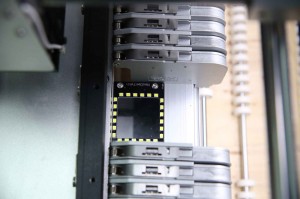

Component Range: Smallest Size: 0201, Biggest Size: TQFP240, Max Height: 5mm

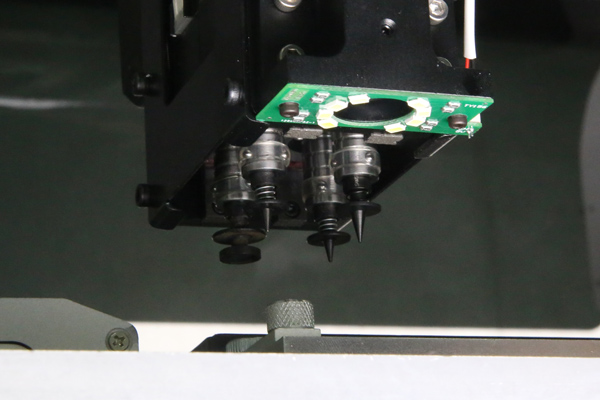

Four placement heads

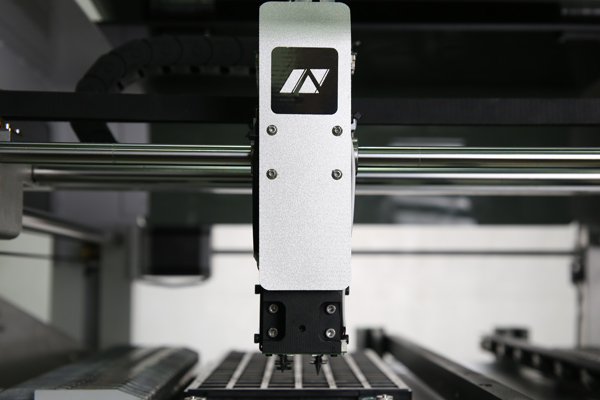

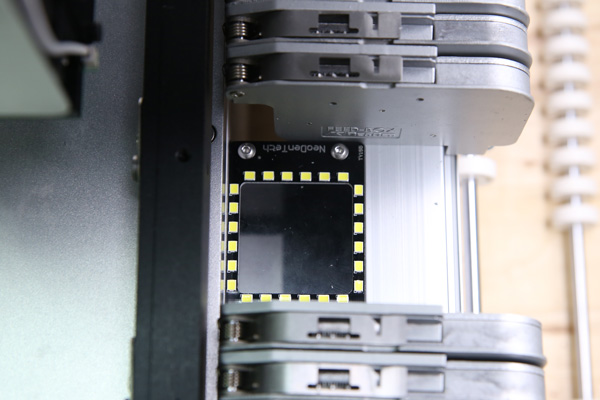

Dual Vision System

Auto Rail

Automatic Electric Feeders

Nozzle information

(1) Function: Select corresponding nozzles (one or more than one all acceptable) according to the components and the nozzle have set on the machine, then the machine will automatic assign to each feeder in order to meet the requirements of single head work or multi heads working together. Also, have detect functions on this item. See the Figure 4.12.

(2) Align: The nozzle will align to the component’s upside on corresponding feeders when click this item

(3) Height: After clicking this item, the nozzle will go down and check whether the pick height is ok. Support do adjustment of pick height on feeder information item if needed.

(4) Pick: After clicking this item, the corresponding nozzle will pick one component and check whether pick position is ok.

Support do adjustment of pick position on feeder information item if needed. After this feature is activated, the part should be removed from the nozzle with a finger or tweezers.

Package

If you need, please feel free to contact us for more information.

Quality control

We have QC person stay on the production lines do to the inspection. All products must have been inspected before delivery. We do inline inspection and final inspection.

1. All raw material checked once it arrive our factory.

2. All pieces and logo and all details checked during production.

3. All packing details checked during production.

4. All production quality and packing checked on final inspection after finished.

About us

Factory

Zhejiang NeoDen Technology Co., Ltd. has been manufacturing and exporting various small pick and place machines since 2010. Taking advantage of our own rich experienced R&D, well trained production, NeoDen wins great reputation from the world wide customers. In our global Ecosystem, we collaborate with our best partners to deliver a more closing sales service, high professional and efficient technical support.

① NeoDen products: Smart series PNP machine, NeoDen K1830, NeoDen4, NeoDen3V, NeoDen7, NeoDen6, TM220A, TM240A, TM245P, reflow oven IN6, IN12, Solder paste printer FP2636, PM3040

② 30+ quality control and technical support engineers, 15+ senior international sales, timely customer responding within 8 hours, professional solutions providing within 24 hours

Certification

Exhibition

FAQ

Q1: What’s your after-sale service?

A: Our quality warranty period is one year. Any quality problem will be solved to customer satisfactions.

Q2: What is your terms of delivery?

A: We accept EXW, FOB, CFR, CIF, etc. You can choose the one which is the most convenient or cost effective for you.

Q3: How far is your factory from the airport and train station?

A: From airport about 2 hours by car, and from train station about 30 minutes.

We can pick up you.

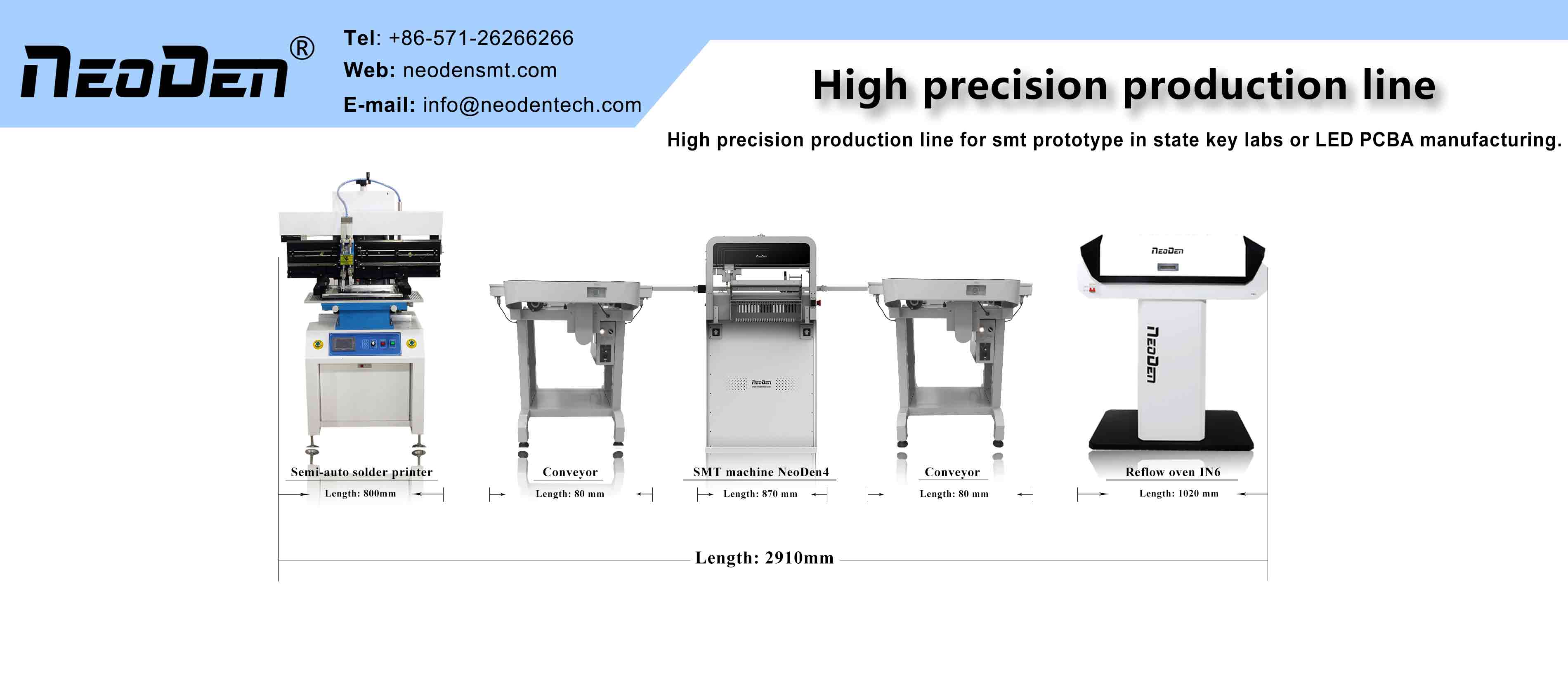

One Stop SMT Equipments Manufacturer

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.