Pick and Place Machine Price

NeoDen4

Pick and Place Machine

The fourth-generation model

Description

Specification

| Product name | Pick and Place Machine Price |

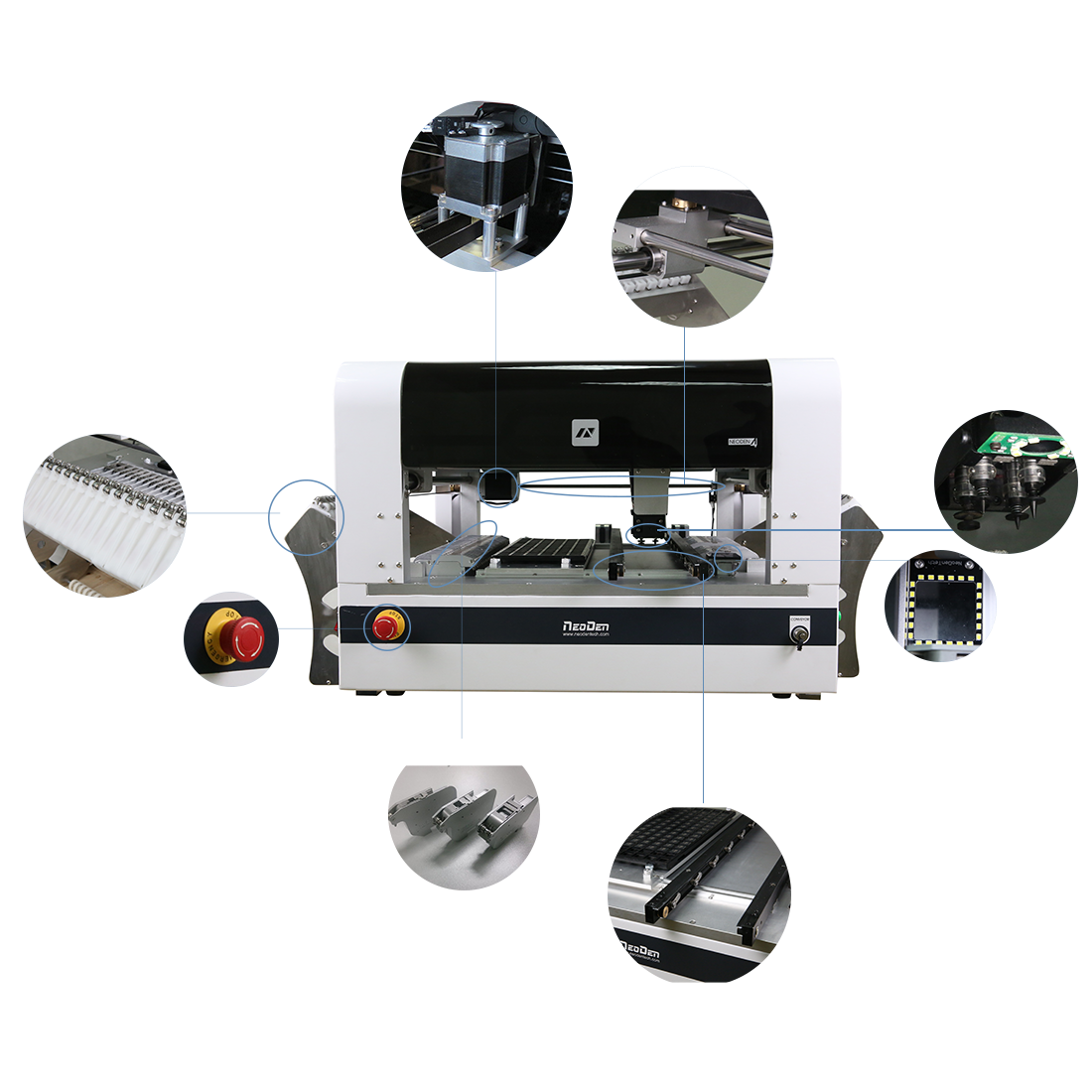

| Machine Style | Single gantry with 4 heads |

| Placement Rate | 4000 CPH |

| External Dimension | L 870×W 680×H 480 mm |

| Max applicable PCB | 290mm*1200mm |

| Feeders | 48pcs |

| Average working power | 220V/160W |

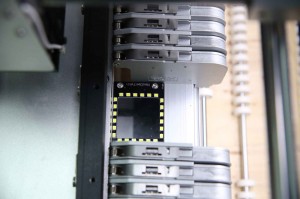

| Component Range | Smallest Size: 0201 |

| Biggest Size: TQFP240 | |

| Max Height: 5mm |

Feature

Number of Feeders:

In addition, the vibration feeder (included) can handle up to 5 separate tubes.

The amount of space available for tray-fed components and short tapes depends on the available real estate on the table.

Any area of the table may be used for components awaiting placement, or for the board under manufacture.

Component Thickness Limitations:

When using tray-fed and short-tape components, the maximum allowable component height is 5mm.

When using tape-and-reel components, we recommend a maximum thickness of 1.8mm for reliable operation.

Details

Electric tape-and-reel feeders, vibration feeders and virtual tray feeders are all supported.

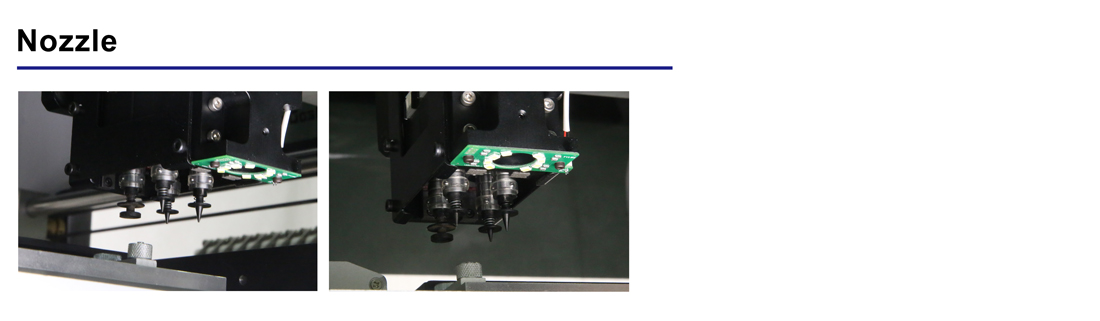

The spring-loaded nozzles simply snap in and pull out of the head.

Any Nozzle can be installed in any of the four locations on the head.

The NeoDen4 features a high-precision, two-camera vision system.

The cameras are made by Micron Technology and are precisely aligned to the nozzles using the single unified configuration/operation application that loads on power-on.

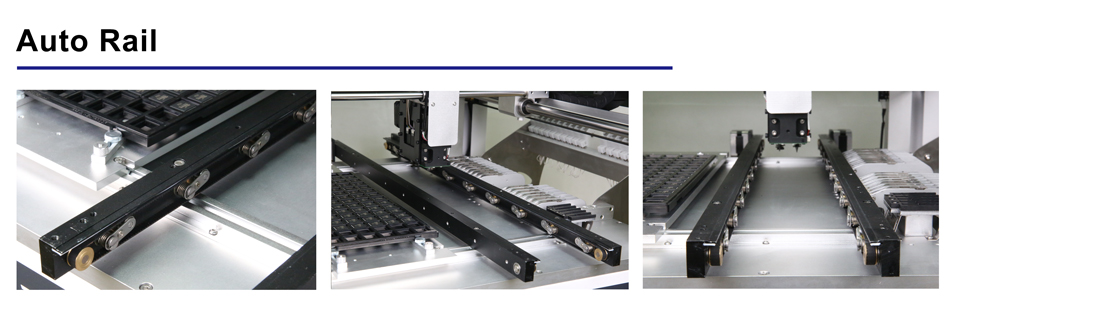

The rail system allows automatic feeding of PCBs, automatic alignment of the board with the camera, and automatic ejection from the front of the machine or the rear.

Rear-ejection is useful when the machine is connected to an optional conveyor that can deliver the finished board directly to the reflow oven or to another NeoDen4.

The NeoDen4 can accommodate up to 48 8mm tape-and-reel feeders on its left and right rails, and any size feeder (8, 12, 16 and 24mm) can be installed in any combination or order on the left and right sides of the machine.

Any area of the table may be used for components awaiting placement, or for the board under manufacture.

Package

If you need, please feel free to contact us for more information.

About us

Factory

3 different R&D teams with total 25+ professional R&D engineers, to ensure the better and more advanced developments and new innovation.

Skilled and professional english support&service engineers, to ensure the prompt response within 8 hours, solution provides within 24 hours.

The unique one among all of the Chinese manufacturers who registered and approved CE by TUV NORD.

Certification

Exhibition

FAQ

Q1: When can I get the price?

A: Usually we quote within 8 hours after we get your inquiry.

Q2: Is there the products tested before shipping?

A: Yes, of course. All of our conveyor belt we all will has been 100% QC before shipping. We test every batch every day.

Q3: Can l visit your factory?

A:By all means, we warmly welcome your arrival, Before you take off from your country, please let us know.

We will show you the way and arrange time to pick you up if possible.

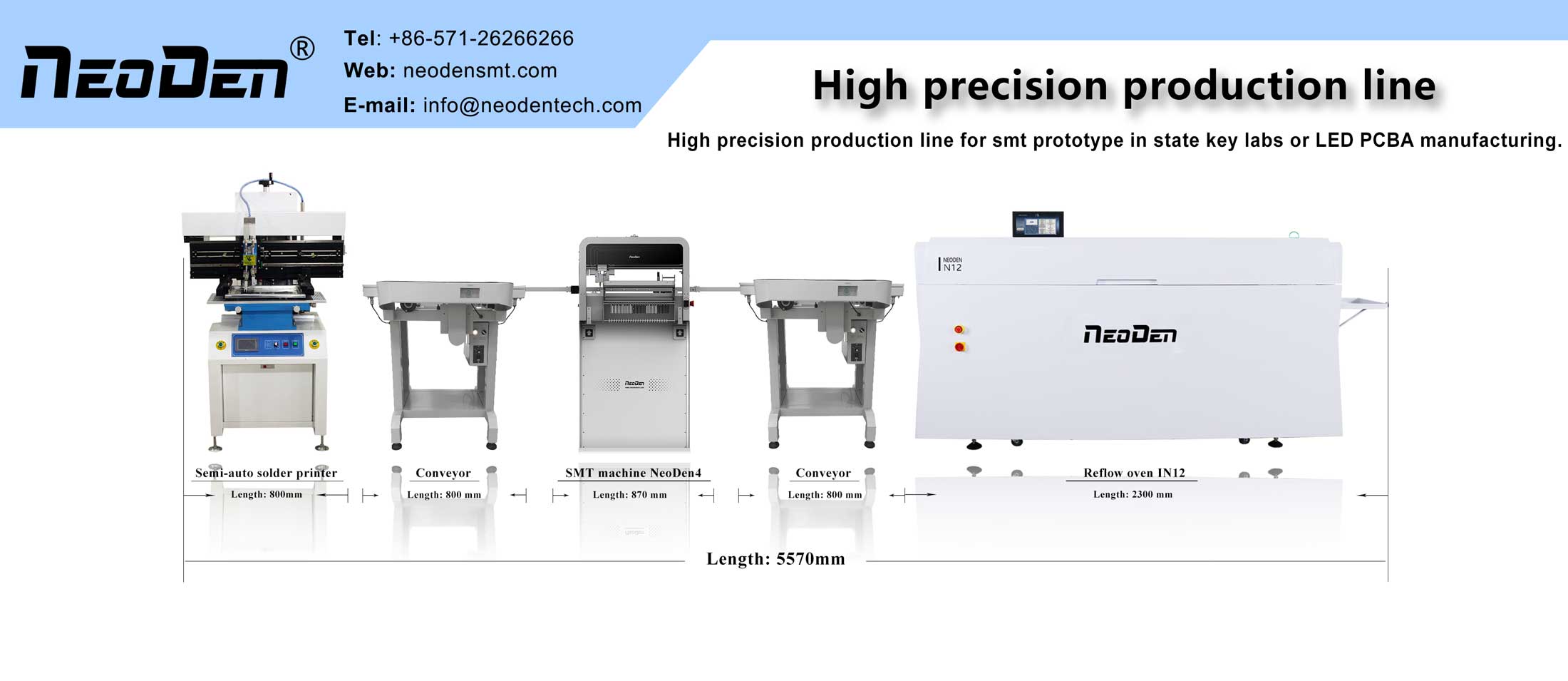

One Stop SMT Equipments Manufacturer

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.