PCB Reflow Solder Machine

PCB Reflow Solder Machine

Specification

1. Smart control with high sensitivity temperature sensor, the temperature can be effectively stabilized.

2. The optimized welding fume filter systems tested by the dedicated airflow simulation software can filter harmful gases as well as ensuring IN12 can keep room temperature, reducing heat loss and reducing working power consumption.

3. Exclusively designed PCB guide device to realize the direct connection between the mesh chain and the conveyor.

Details

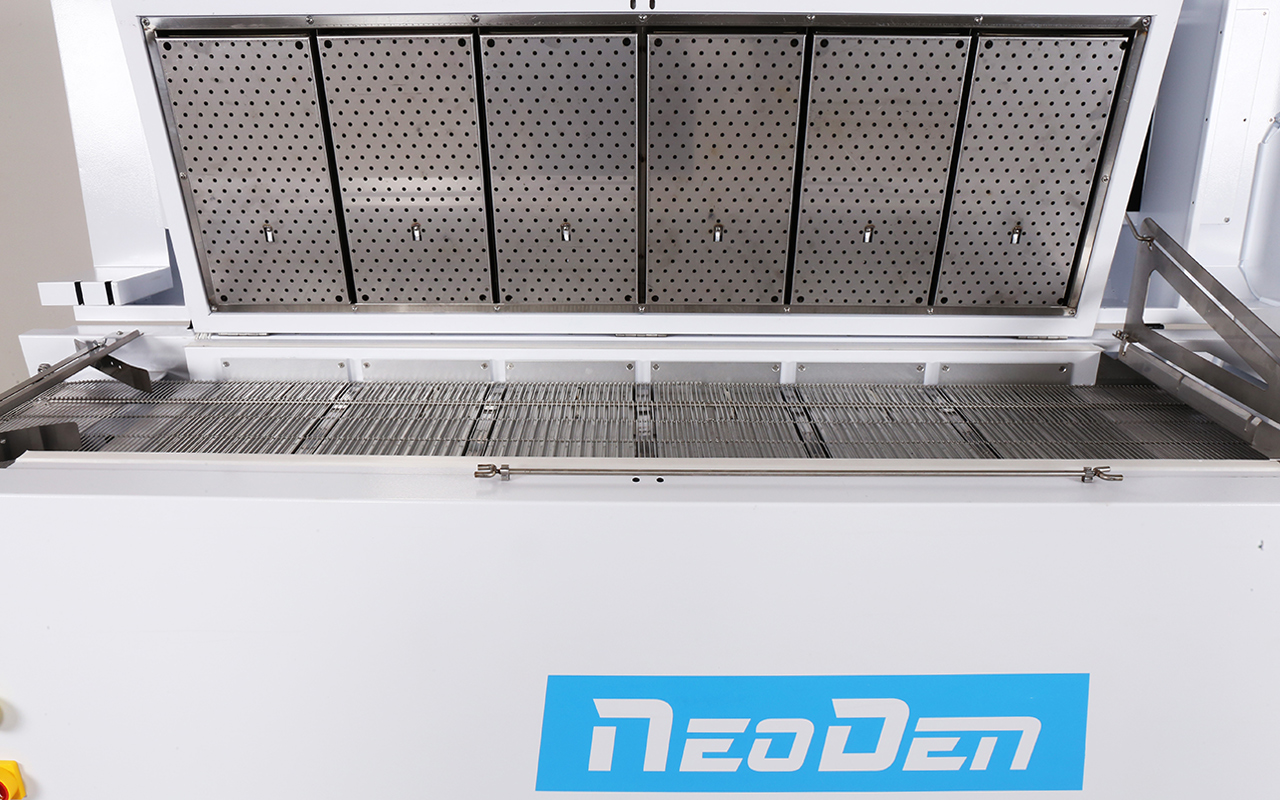

12 temperature zones

High temperature control accuracy

Uniform temperature distribution in the thermal compensation area

Cooling zone

Independent circulating air design

Isolates the influence of the external environment

Energy saving & Eco-friendly

Welding smoke filtering system

low power consumption, low power supply requirements

Operation panel

Hidden screen design

convenient for transportation

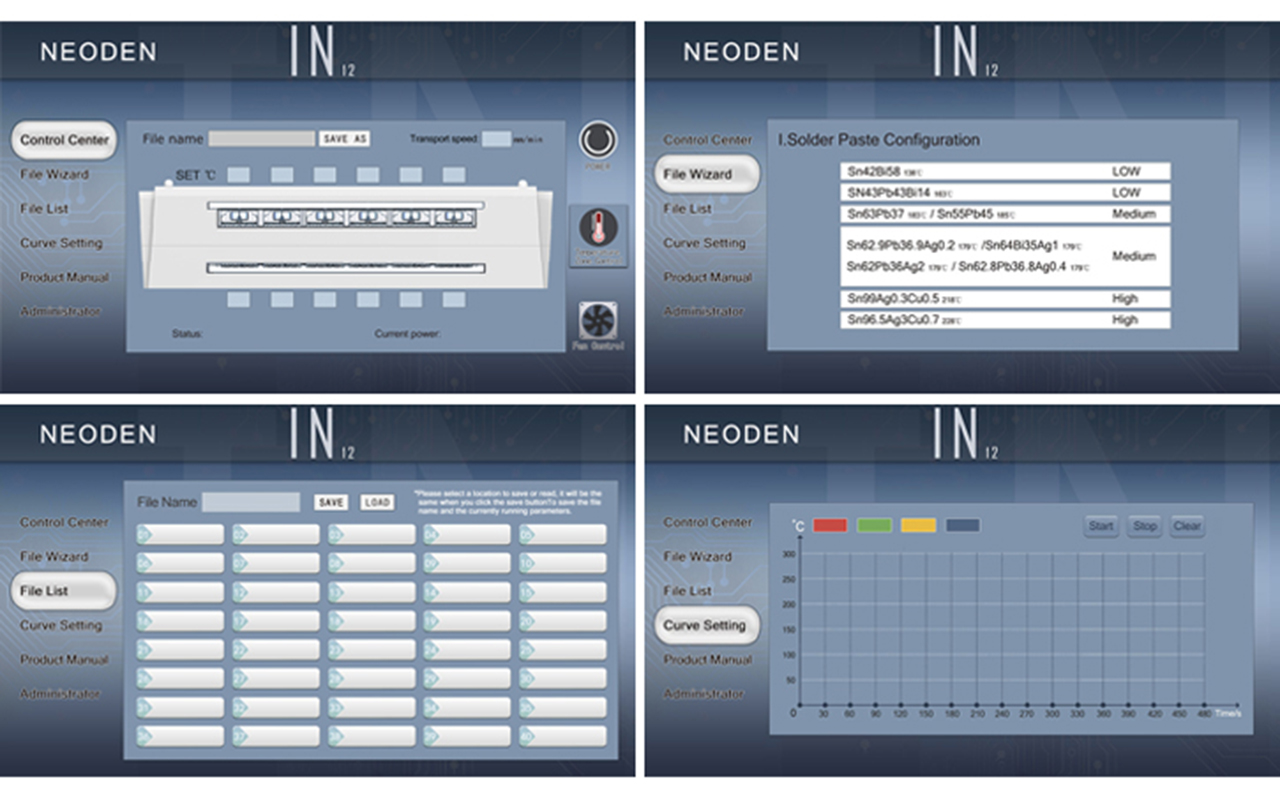

Intelligent control system

Custom developed intelligent control system

Temperature curve can be displayed

Elegant appearance

In line with high-end use environment

Lightweight, miniaturization, professional

Feature

Product name: PCB Reflow Solder Machine

Cooling fan: Upper4

Conveyor speed: 50~600 mm/min

Temperature range: Room temperature~300℃

PCB temperature deviation: ±2℃

Max soldering height(mm): 35mm (includes PCB thickness)

Max soldering width (PCB Width): 350mm

Length process chamber: 1354mm

Electricity supply: AC 220v/single phase

Machine size: L2300mm×W650mm×H1280mm

Heat-up time: 30 min

Net weight: 300Kgs

Installation Attentions

Voltage requirement 220V;

The electricity wire need no less than 2.5mm2, it’s better to directly use 4mm2 (If 2.5mm2, then it can only connect with one set of IN12 Reflow oven, other equipment Will not be allowed to connect together.

The machine should be set in standard SMT workshop, stay away from flammable and explosive if couldn’t meet previous requirements.

Exposed wire harness should be well protected, prohibit to expose at the passage or flue in case of causing any accident.

FAQ

Q1: Do you provide software updates?

A: Customers who buy our machine, we can offer free upgrades software for you.

Q2: Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT Machine, Pick and Place Machine, Reflow Oven, Screen Printer, SMT Production Line and other SMT Products.

Q3: Can we customize the machine?

A: Of course. All of our machines can be customized.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.