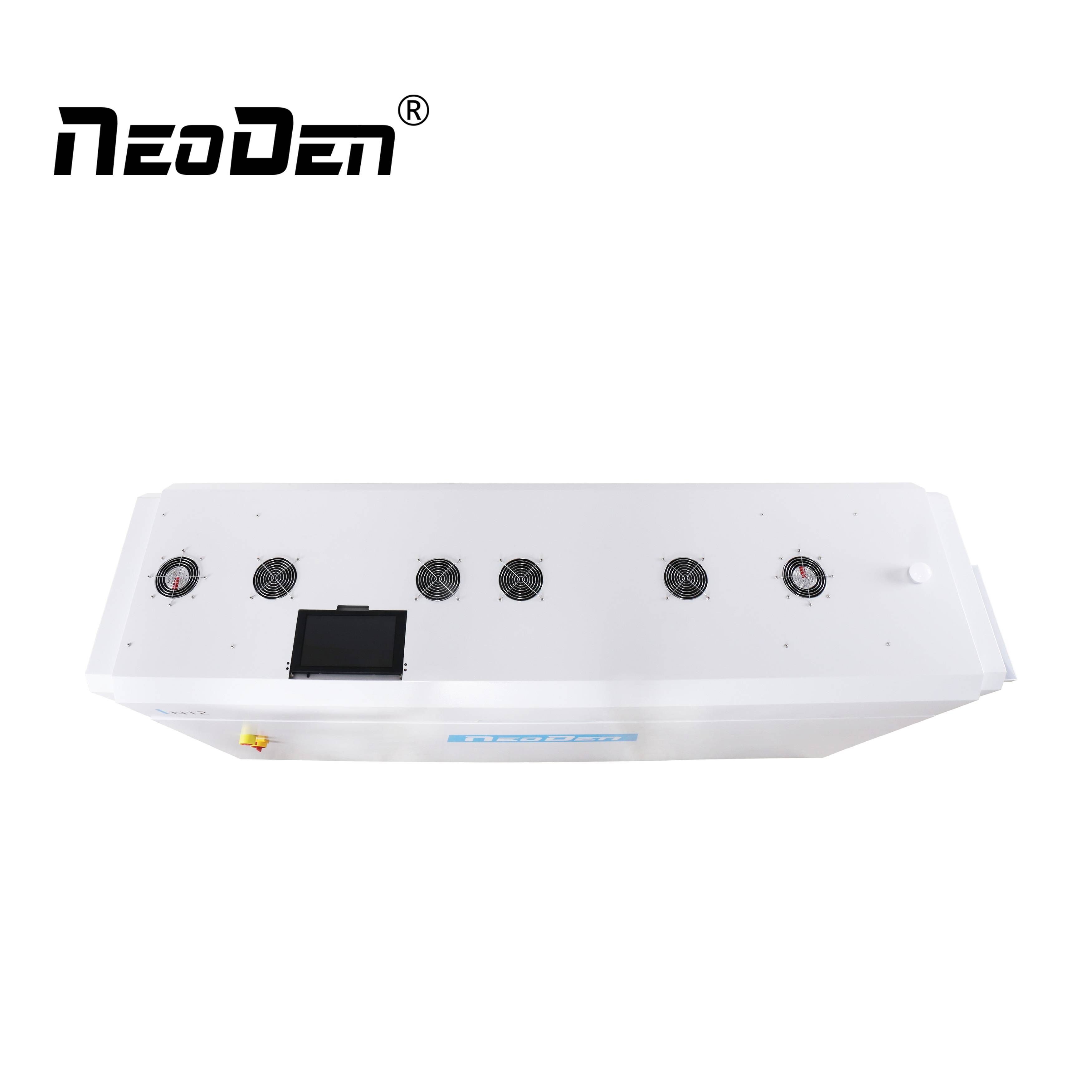

PCB reflow machine reflow oven machine NeoDen IN12

PCB reflow machine reflow oven machine NeoDen IN12

Description

Features

1. The control system has features of high integration, timely response, low failure rate and convenient maintenance.

2. The unique design of heating module has the characteristics of high temperature control accuracy, uniform temperature distribution in the thermal compensation area, high thermal compensation efficiency and low power consumption.

3. The optimized welding fume filter systems tested by the dedicated airflow simulation software can filter harmful gases as well as ensuring IN12 can keep room temperature, reducing heat loss and reducing working power consumption.

4. The unique heating plate design effectively ensures IN12 will cool down evenly once the heating is stopped, and effectively prevents the deformation and damage caused by the rapid temperature drop.

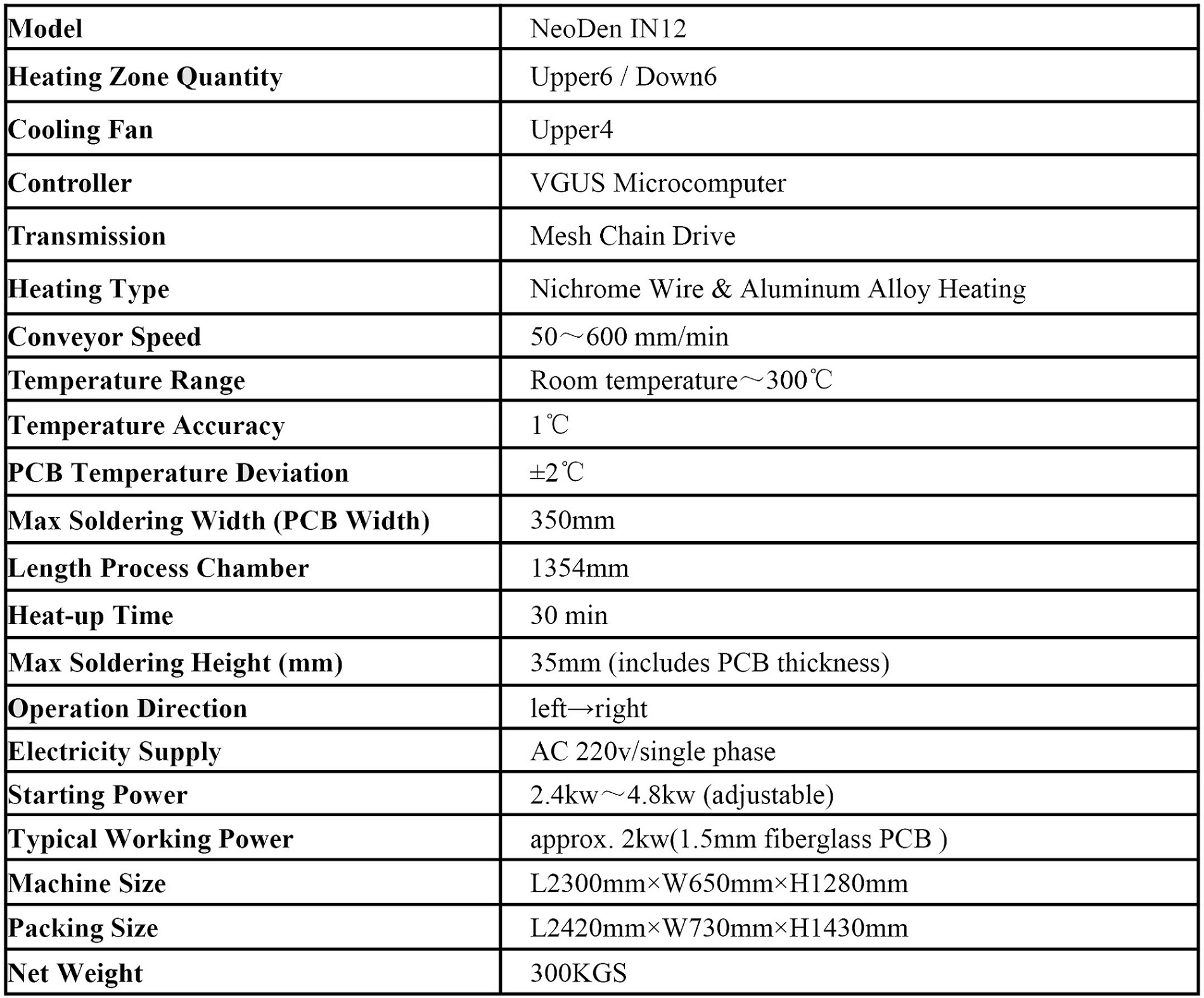

Specification

Details

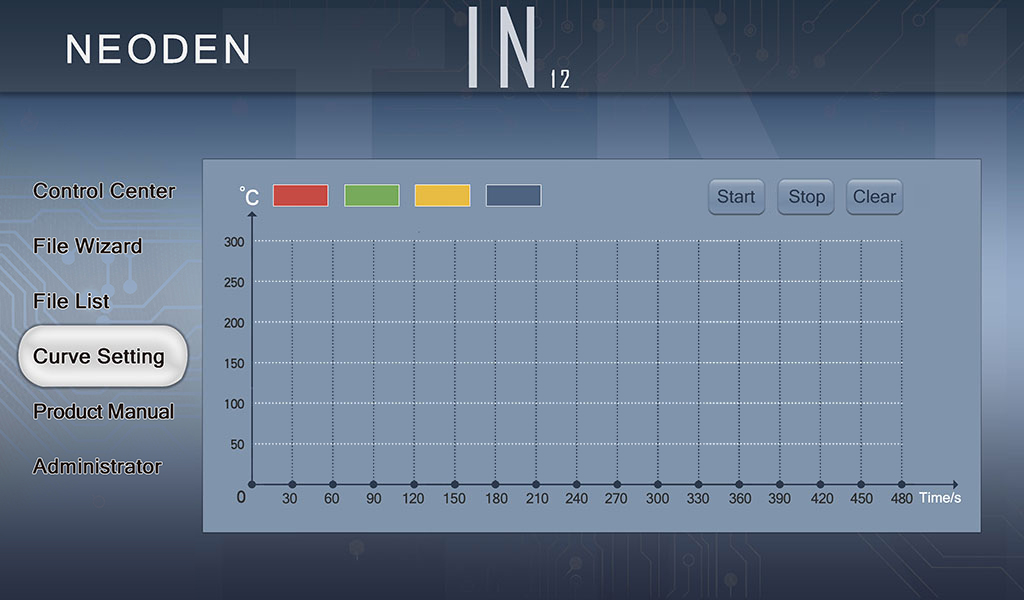

Real-time measurement

1- PCB soldering temperature curve can be displayed based on real-time measurement.

2- Professional and unique 4-way board surface temperature monitoring system, can give timely and comprehensive data feedback in actual operation.

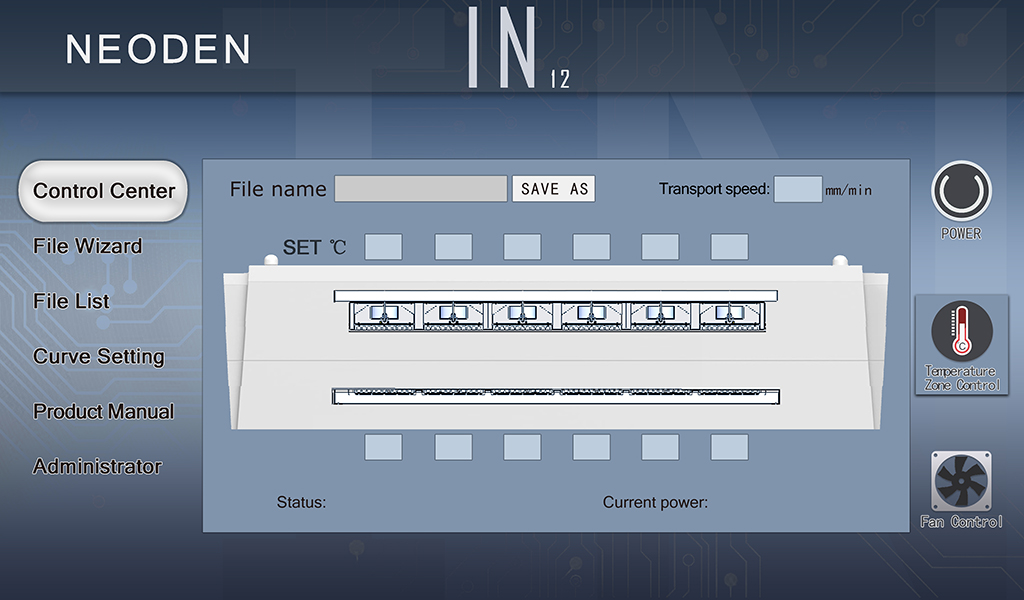

Intelligent control system

1-Heat insulation protection design, the casing temperature can be effectively controlled.

2- Smart control with high sensitivity temperature sensor, the temperature can be effectively stabilized.

3-Intelligent, the custom developed intelligent control system, easy to use and powerful.

Energy saving & Eco-friendly

1-Built-in welding smoke filtering system, effective filtration of harmful gases.

2-Energy saving, low power consumption, low power supply requirements, the ordinary civil electricity can meet the use.

3-The internal thermostat is made of stainless steel, which is environment friendly and has no peculiar smell.

Attentive design

1-Hidden screen design is convenient for transportation, easy to use.

2-The upper temperature cover is automatically limited once opened, effectively ensuring the personal safety for the operators.

2. The electricity wire need no less than 2.5mm2, it’s better to directly use 4mm2 (If 2.5mm2, then it can only connect with one set of IN12 Reflow oven, other equipment will not be allowed to connect together.

3. The machine should be set in standard SMT workshop, stay away from flammable and explosive if couldn’t meet previous requirements.

4. Exposed wire harness should be well protected, prohibit to expose at the passage or flue in case of causing any accident.

Provide one-stop SMT assembly production line

Related products

FAQ

Q1: This is the first time I use this kind of machine, is it easy to operate?

A: Yes. There are English manual and guide video that show you how to use machine.

If there is any doubt in the process of operating the machine, please feel free contact us.

We also provide overseas on-site service.

Q2: Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT Machine, Pick and Place Machine, Reflow Oven, Screen Printer, SMT Production Line and other SMT Products.

Q3: Is it hard to use these machines?

A: No,not hard at all.For our previous clients,at most 2 days is enough to learn to operate the machines.

About us

Exhibition

Certification

Factory

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.