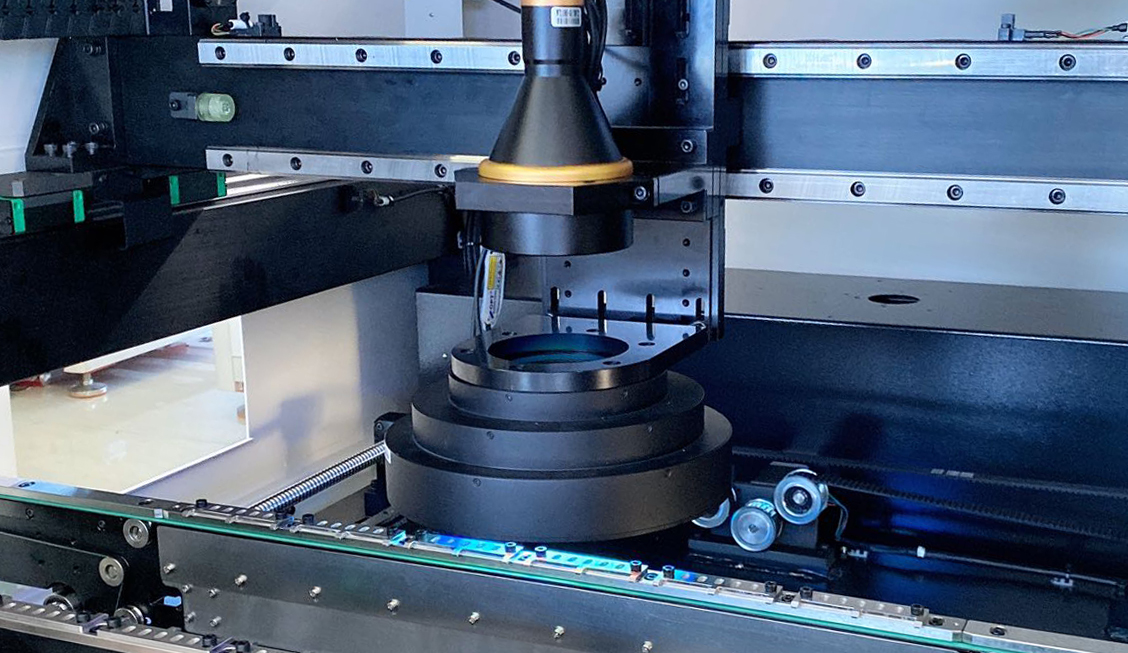

Online AOI Automatic Testing Machine

Online AOI Automatic Testing Machine

Machine characteristics

HD color global exposure digital camera speed increase 30% .

High depth of field telecentric lens, which can measure the solder joints on the side of high components.

Support the detection of smt front, back and dip station.

Support 0201 and 01005 packaged component inspection.

CAD data import, automatic linking component library, automatic color picking.

True non-stop offline programming and program update.

MES data docking to realize intelligent factory.

Support multi-line centralized management and remote service.

Specification

| Product name | Online AOI Automatic Testing Machine |

| Model | ALE |

| PCB Thickness | 0.6mm~6mm |

| Max. PCB Size (X x Y) | 510mm x 460mm |

| Min. PCB Size (Y x X) | 50mm x 50mm |

| Max. Bottom Gap | 50mm |

| Max. Top Gap | 35mm |

| Moving speed | 1500mm/Sec(Max) |

| Transmission height from the ground | 900±30mm |

| Transmission Method | One Stage Lane |

| PCB clamping method | Edge locking substrate clamping |

| Weight | 750KG |

Features

Image Parameters

Camera: GigE Vision(Gigabit network interface)

Resolution: 2448*2048(500 Mega Pixels)

FOV: 36mm*30mm

Resolution: 15μm

Lighting System: Multi-angle surrounding LED light source

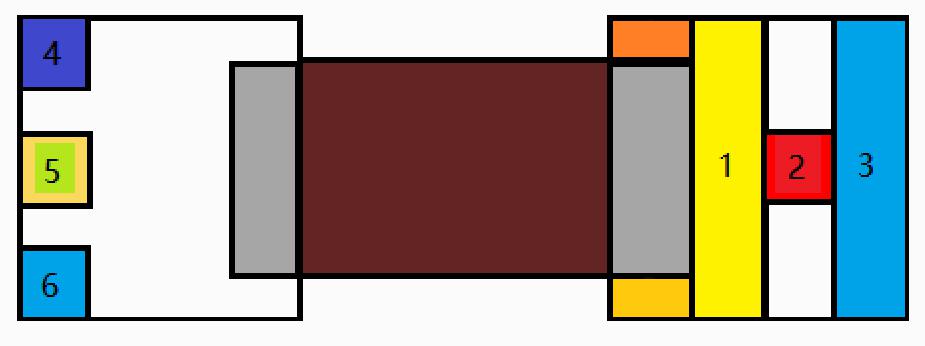

Compreshensive Pad Defect Detection

Divide the pad into multiple areas, each area has the characteristics of good and bad products, set the corresponding detection standards to measure.

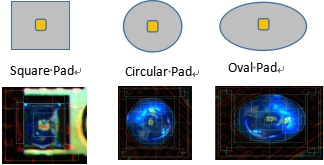

Compatible with Various Shapes of Pads

Wave soldering algorithm supports various shapes of pads, positioning is more accurate.

Reference point positioning + pad positioning + body positioning

The industry's strongest positioning method, easy to deal with a variety of severely deformed boards, especially for flexible boards, server motherboards and other products.

Packaging & Shipping

Packaging: One piece in one wooden case

Suitable quantity to an export wooden case

Other packing accessories in regular

Customer required packing is available

Shipping: by air, sea, or express

Delivery time: about 15~30 days after order details and production confirmed.

Provide one-stop SMT assembly production line

About us

Our Factory

Quick facts about NeoDen

Owned the own machining center, skilled assembler, tester and QC engineers, to ensure the strong abilities for NeoDen machines manufacturing,quality and delivery.

The unique one among all of the Chinese manufacturers who registered and approved CE by TUV NORD.

NeoDen supplies life-long technical support and service for all of the NeoDen machines, moreover, regular software updates based on the using experiences and actual daily request from the endusers.

Certification

Exhibition

If you need, please feel free to contact us!

FAQ

Q1: When can I get the quotation?

A: We usually quote within 8 hours after we get your inquiry.

If you are very urgent to get the price, please tell us so that we will regard your inquiry priority.

Q2: How far is your factory from the airport and train station?

A: From airport about 2 hours by car, and from train station about 30 minutes.

We can pick up you.

Q3: Can I request to change the form of packaging and transportation?

A: Yes, We can change the form of the packaging and transportation according to your request, but you have to bear their own costs incurred during this period and the spreads.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.