Pick And Place Desktop – Surface mounting machine NeoDen K1830 – Neoden

Pick And Place Desktop – Surface mounting machine NeoDen K1830 – Neoden Detail:

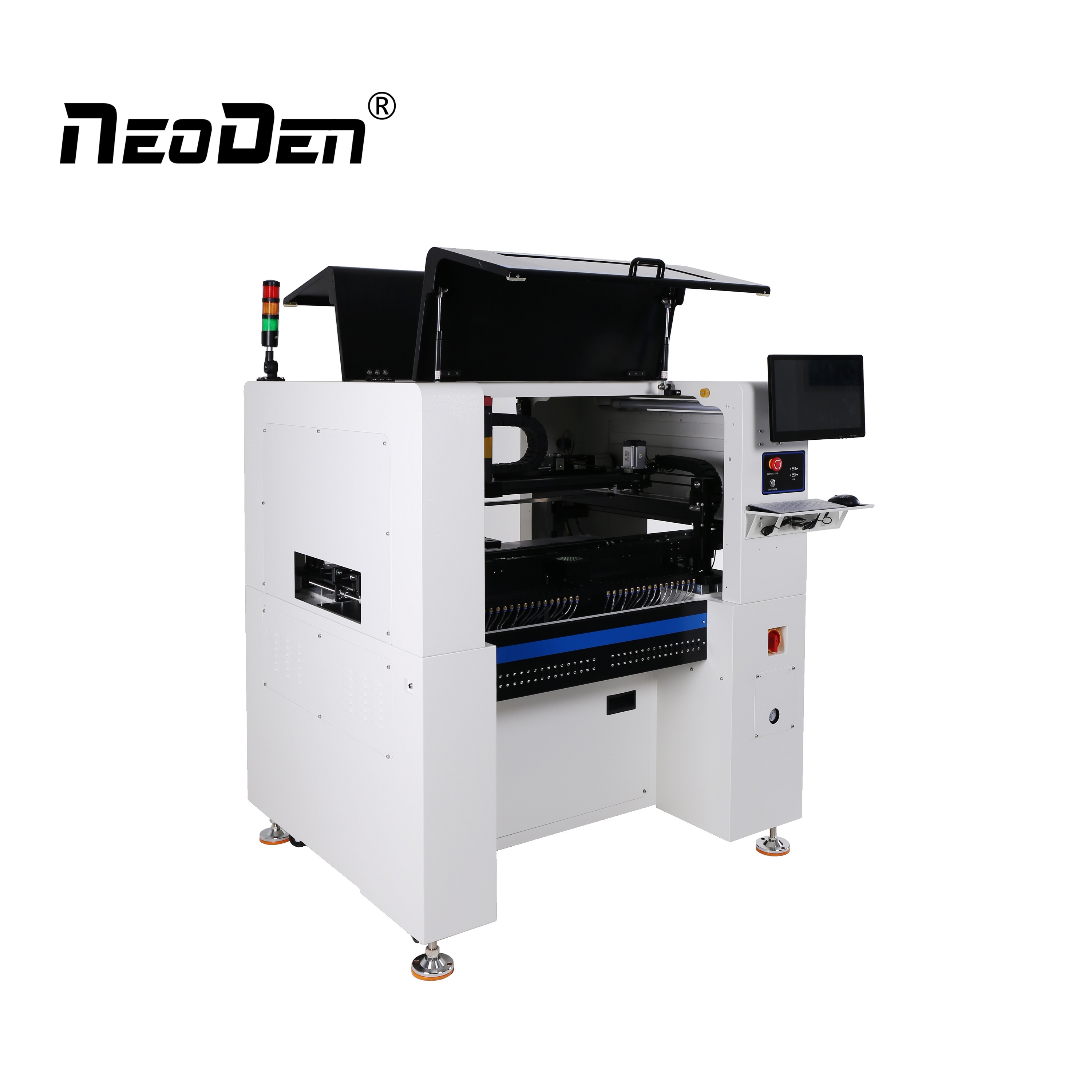

Pick and Place Machine NeoDen K1830

NeoDen K1830 is designed for small-medium productional factories.

With affordable price and good mounting function, it could be your prior choice for a medium speed production pick and place machine.

Surface mounting machine NeoDen K1830‘s high resolution and high speed component camera system improves the overall speed of the machine.

Ethernet communication interface for all internal signal travel makes the machine to perform more stable and flexible.

PCB location can be calibrated automatically and promptly,based on the correct and specific placement request.

Product Features

Head

8 Synchronized Nozzles which ensure a repeatable placement accuracy with high speed

System

Machine runs on highly stable and secure Linux operating system

Camera

Double mark cameras to reach at extreme end feeders for better calibration

Interface

Ethernet communication interface for all internal signal travel makes the machine to perform more

stable and flexible

Feeder

Picking location of pneumatic feeder can be calibrated automatically and promptly,to ensure easy

operation and high efficiency

Calibrate

PCB location can be calibrated automatically and promptly,based on the correct and specific placement

request

1. Surface mounting machine NeoDen K1830 has 8 Synchronized Nozzles which ensure a repeatable placement accuracy with high speed

2. Closed loop Servo control system with feedback makes the machine to function more accurate.

3. Double mark cameras to reach at extreme end feeders for better calibration.

Our Service

1. Provide video tutorial after purchasing the product.

2. 24-hour online support.

3. Professional after-sales technical team.

4. Free broken parts(Within 1 Year warranty).

Our Company

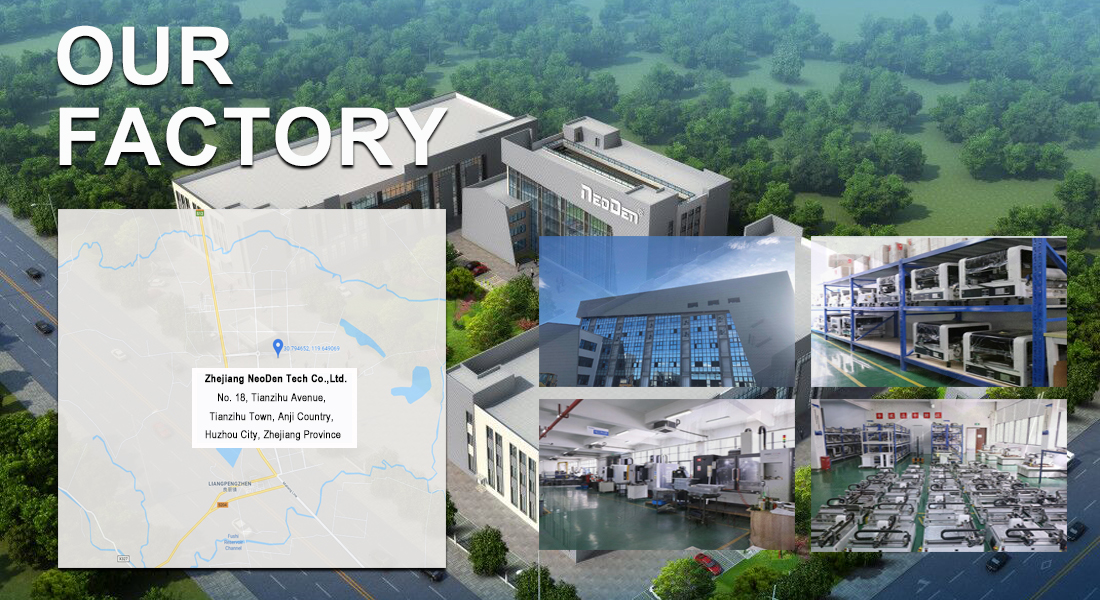

Hangzhou NeoDen Technology Co., LTD., founded in 2010, in this decade, we independently developed NeoDen4, NeoDen IN6, NeoDen K1830, NeoDen FP2636 and other SMT products, which sold well all over the world. So far, we have sold more than 10,000pcs machines and exported them to over 130 countries around the world, establishing a good reputation in the market. In our global Ecosystem, we collaborate with our best partner to deliver a more closing sales service, high professional and efficient technical support.

We believe that great people and partners make NeoDen a great company and that our commitment to Innovation, Diversity and Sustainability ensures that SMT automation is accessible to every hobbyist on everywhere.

Provide one-stop SMT assembly production line

Solder Printer+Conveyor+NeoDen Pick and Place Machine+Conveyor+Reflow Oven

Product Video

Product detail pictures:

Related Product Guide:

Defect analysis of reflow welding

We're going to commit ourselves to giving our esteemed buyers using the most enthusiastically considerate solutions for Pick And Place Desktop – Surface mounting machine NeoDen K1830 – Neoden , The product will supply to all over the world, such as: Rotterdam, Mexico, Accra, We've been consistently broadening the market within Romania in addition to preparation punching in extra premium quality merchandise connected with printer on t shirt so that you can Romania. Most people firmly believe we've the whole capacity to provide you happy solutions.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.