Smd Led Mounting Machine – SMT pick and place machine|PCB mounter machine – Neoden

Smd Led Mounting Machine – SMT pick and place machine|PCB mounter machine – Neoden Detail:

NeoDen K1830 SMT pick and place machine with 8 heads video

NeoDen K1830 SMT pick and place machine with 8 heads

Features

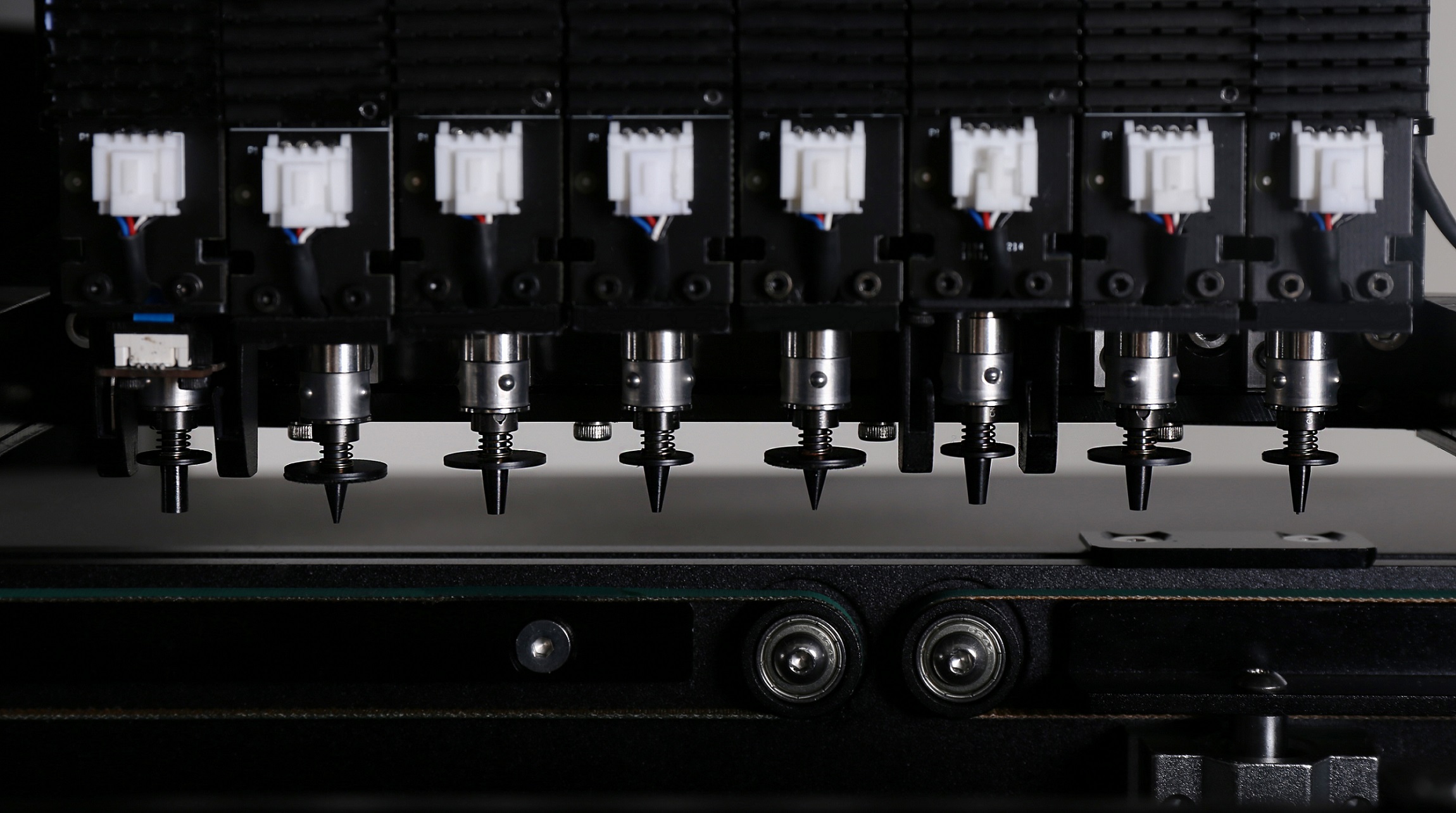

Head

8 Synchronized Nozzles which ensure a repeatable placement accuracy with high speed

System

Machine runs on highly stable and secure Linux operating system

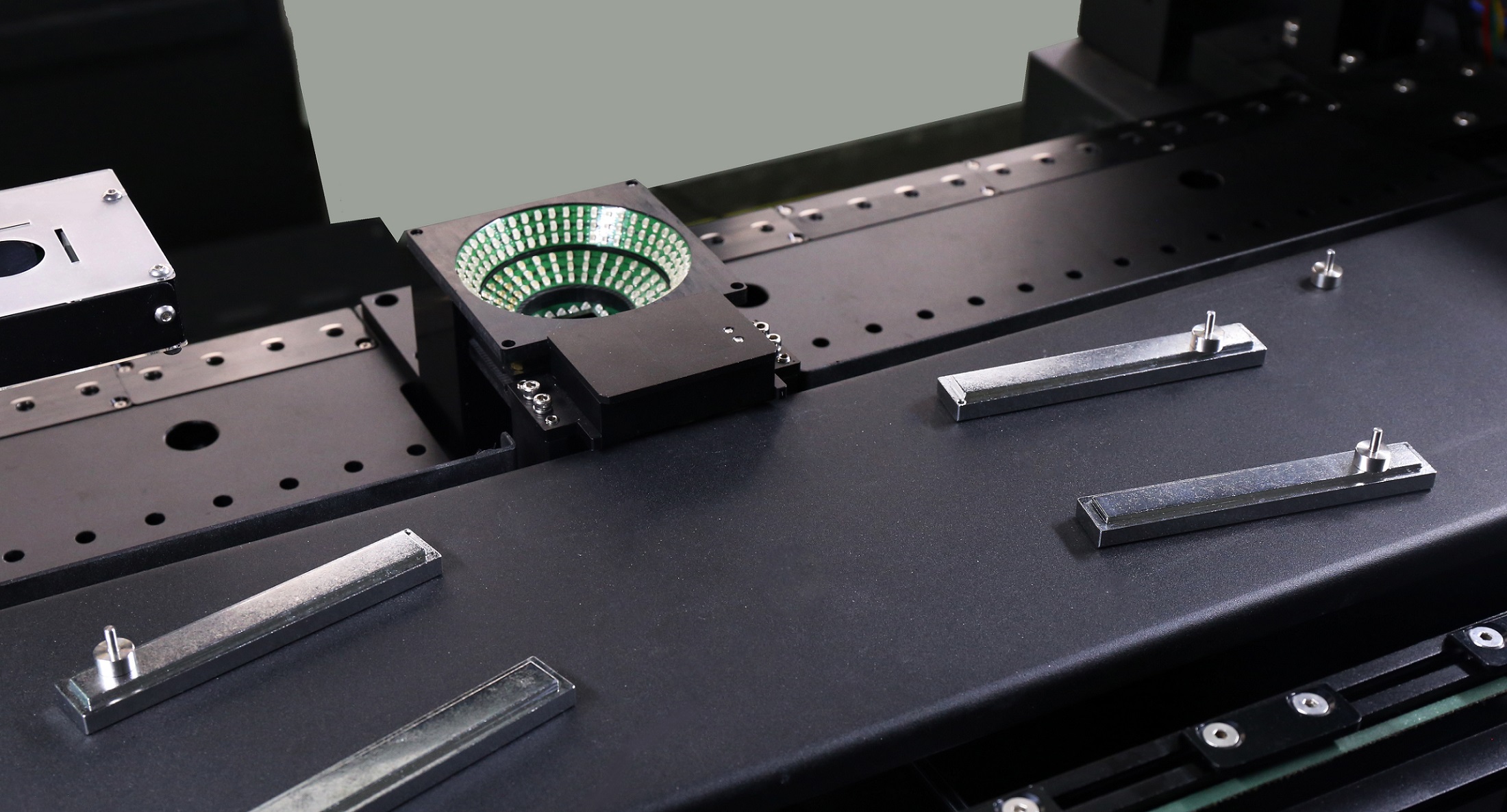

Camera

Double mark cameras to reach at extreme end feeders for better calibration

Interface

Ethernet communication interface for all internal signal travel makes the machine to perform more

stable and flexible

Feeder

Picking location of pneumatic feeder can be calibrated automatically and promptly,to ensure easy

operation and high efficiency

Calibrate

PCB location can be calibrated automatically and promptly,based on the correct and specific placement

request

Product Detail

1-8 Synchronized Nozzles which ensure a repeatable placement accuracy with high speed.

2-Machine runs on highly stable and secure Linux operating system.

1-Double mark cameras to reach at extreme end feeders for better calibration.

2-High resolution and high speed component camera system improves the overall speed of the machine.

1-Closed loop Servo control system with feedback makes the machine to function more accurate.

2-Picking location of pneumatic feeder can be calibrated automatically and promptly,to ensure easy operation and high efficiency.

Description

| Model | NeoDen K1830 |

| Nozzle Q’ty | 8 |

| Reel Tape Feeder Q’ty(Max) | 66 (Electric / Pneumatic) |

| IC Tray Feeder Q’ty | 10 (In Succession) |

| Max PCB size | 540*300mm(In Single Step) |

| Smallest Component Size | 0201(Electric Feeder Available) |

| IC Packages | QFP, SSOP, QFN, BGA |

| Placement accuracy | 0.01mm |

| Max Component Height | 18mm |

| Max Placement Speed | 16,000CPH |

| Component Recognition | High Resolution Flying Vision Camera System |

| PCB Fiducial Recognition | High Precision Mark Camera |

| PCB Loading | Synchronized 3 Stages Internal Conveyor system |

| PCB Transfer Direction | Left→Right |

| Air Supply | >0.6MPa |

| Power | 500W |

| Voltage | 220V/50HZ & 110V/60HZ |

| Net Weight | 280kgs |

| Gross Weight | 360kgs |

| Machine Dimensions | 1288×1062×1291mm(Without Tri-color Light) |

| Packing Dimensions | 1420×1220×1665mm |

Feeder setting

Select one feeder, tick “Apply”, then its related info can be edited such as feeder exchange, feeder, nozzle, IC tray feeder etc.

The setting sequence for them should be: Feeder (or IC tray feeder)→ Feeder basic information→ Nozzle.

PS.: 1) For feeders 1-66, the IC tray feeder is in disabled condition. 2) Feeder exchange depends on application condition, if the tape reel was installed on wrong feeder, you can directly use feeder exchange to solve it.

If you need, please don’t hesitate to send your inquiry.

Provide one-stop SMT assembly production line

Related Products

|

|

|

| Stencil printer FP2636 | Automatic conveyor J12 | Reflow Oven IN6 |

FAQ

Q1: How can I buy machine from you ?

A: (1)Consult us on line or by e-mail

(2)Negotiate and confirm the final price , shipping , payment method and other terms

(3)Send you the perfroma invoice and confirm your order

(4)Make the payment according to the method put on proforma nvoice

(5)We prepare your order in terms of the proforma invoice after confirming your full payment . And 100% quality check before shipping

(6)Send your order via express or by air or by sea .

Q2: What’s the way of shipping?

A: These are all heavy machines; we suggest you use cargo ship. But components for mending the machines, air transportation would be fine.

Q3: Is it hard to use these machines?

A: No,not hard at all.For our previous clients,at most 2 days is enough to learn to operate the machines.

Our Company

NeoDen provides a full SMT assembly line solutions, including SMT reflow oven, wave soldering machine, pick and place machine, solder paste printer, PCB loader, PCB unloader, chip mounter, SMT AOI machine, SMT SPI machine, SMT X-Ray machine, SMT assembly line equipment, PCB production Equipment SMT spare parts, etc any kind SMT machines you may need, please feel free to contact us.

Hangzhou NeoDen Technology Co., Ltd

Web: www.smtneoden.com

Email: info@neodentech.com

Product detail pictures:

Related Product Guide:

Defect analysis of reflow welding

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our management ideal for Smd Led Mounting Machine – SMT pick and place machine|PCB mounter machine – Neoden , The product will supply to all over the world, such as: India, Rotterdam, Somalia, we rely on own advantages to build a mutual-benefit commerce mechanism with our cooperative partners. As a result, we've gained a global sales network reaching the Middle East, Turkey, Malaysia and Vietnamese.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.