SMT Reflow Solder – Desktop conveyor reflow soldering oven – Neoden

SMT Reflow Solder – Desktop conveyor reflow soldering oven – Neoden Detail:

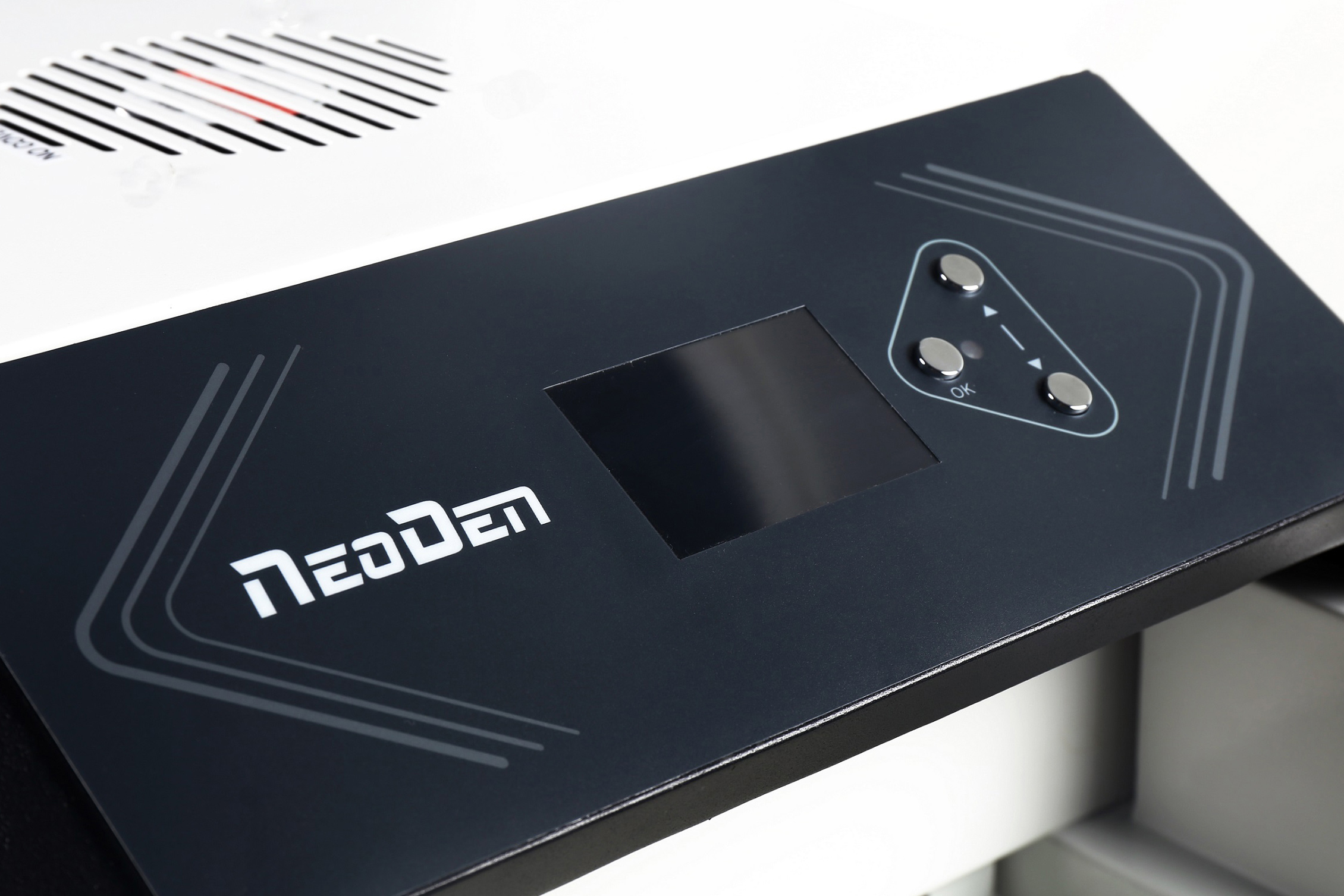

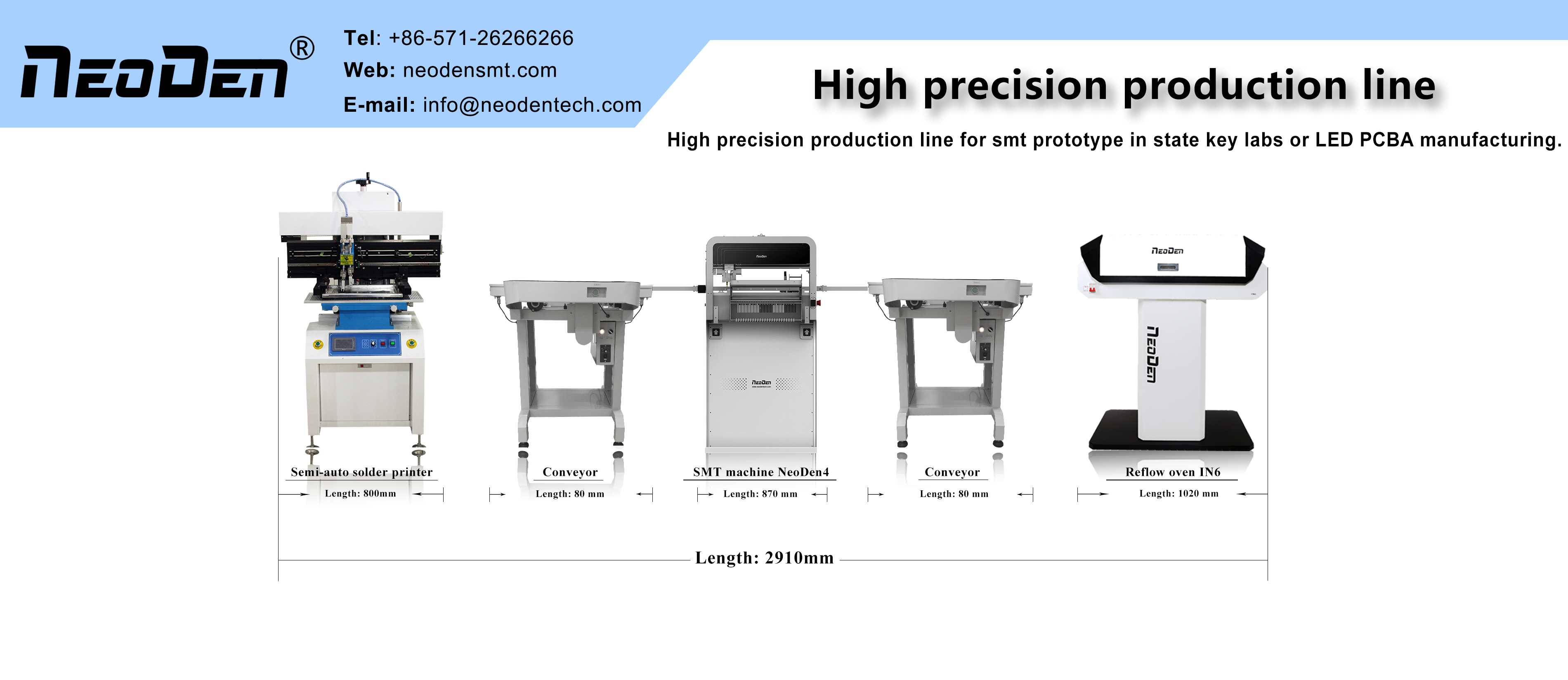

Desktop conveyor reflow soldering oven

Brief Introduction

IN6 is a newly designed, environmentally friendly reflow oven with stable performance. It can achieve full hot-air convection, excellent soldering performance. It has 6 temperature zone, light and compact. Intelligent temperature control with high sensitivity temperature sensor, temperature can be stable within ±0.2°C. It adopts Japan NSK hot air motor bearing and Swiss imported heating wire, which is durable and stable. CE approved, provide authoritative quality assurance.

Specification

| Product Name | Desktop conveyor reflow soldering oven |

| Power requirement | 110/220VAC 1-phase |

| Power max. | 2KW |

| Heating zone quantity | Upper3/ down3 |

| Conveyor speed | 5 – 30 cm/min (2 – 12 inch/min) |

| Standard Max Height | 30mm |

| Temperature control range | Room temperature~300 degree celsius |

| Temperature control accuracy | ±0.2 degree celsius |

| Temperature distribution deviation | ±1 degree celsius |

| Soldering width | 260 mm (10 inch) |

| Length process chamber | 680 mm (26.8 inch) |

| Heat-up time | approx. 25 min |

| Dimensions | 1020*507*350mm(L*W*H) |

| Packing Size | 112*62*56cm |

| N.W./ G.W. | 49KG/64kg (without working table) |

Detail

Heating zones

6 zones design, (3 top, 3 bottom)

Full hot-air convection

Intelligent control system

Several working files can be stored

Color touch screen

Saving energy and Eco-friendly

Built-in solder smoke filtering system

Reinforced heavy-duty carton package

Quality control

We have QC person stay on the production lines do to the inspection.

All products must have been inspected before delivery.we do inline inspection and final inspection.

1. All raw material checked once it arrive our factory.

2. All pieces and logo and all details checked during production.

3. All packing details checked during production.

4. All production quality and packing checked on final inspection after finished.

Related products

|

|

|

|

| Stencil printer FP2636 | SMT machine NeoDen4 | Automatic conveyor J12 | Pick and place machine K1830 |

FAQ

Q1: Are you trading company or manufacturer?

A: We are professional manufacturer specialized in SMT production line. And we trade our products with our clients directly.

Q2: Can you do OEM and ODM?

A: Yes, OEM and ODM are both acceptable.

Q3: When can I get the price?

A: Usually we quote within 8 hours after we get your inquiry.

About us

If you need, please feel free to contact us for more information.

Product detail pictures:

Related Product Guide:

Defect analysis of reflow welding

As for competitive prices, we believe that you will be searching far and wide for anything that can beat us. We can state with absolute certainty that for such quality at such prices we are the lowest around for SMT Reflow Solder – Desktop conveyor reflow soldering oven – Neoden , The product will supply to all over the world, such as: United Arab Emirates, United Kingdom, New Orleans, With the development of the society and economy, our company will continue the "loyalty, dedication, efficiency, innovation" spirit of enterprise, and we will always adhere to the management idea of "would rather lose gold, do not lose customers heart". We will serve the domestic and foreign businessmen with sincere dedication, and let us create bright future together with you!

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.