Pcb Solder Printer – SMT automatic printer screen printing machine – Neoden

Pcb Solder Printer – SMT automatic printer screen printing machine – Neoden Detail:

SMT automatic printer screen printing machine

Description

Specification

SMT automatic printer screen printing machine is easy to learn and use high precision and high stability.

| Product name | SMT automatic printer screen printing machine |

| Maximum board size(X x Y) | 450mm x 350mm |

| Minimum board size(X x Y) | 50mm x 50mm |

| PCB thickness | 0.4mm~6mm |

| Warpage | ≤1% Diagonal |

| Maximum board weight | 3Kg |

| Board margin gap | Configuration to 3mm |

| Maximum bottom gap | 20mm |

| Transfer speed | 1500mm/s(Max) |

| Transfer height from the ground | 900±40mm |

| Transfer orbit direction | L-R,R-L,L-L,R-R |

| Machine weight | Appro.1000Kg |

Features

Accurate optical positioning system

Four way light source is adjustable, light intensity is adjustable, light is uniform, and image acquisition is more perfect;Good identification (including uneven mark points), suitable for tinning, copper plating,Gold plating, tin spraying, FPC and other types of PCB with different colors.

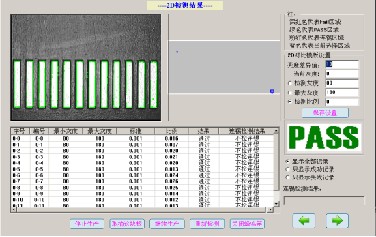

2D solder paste printing quality inspection and SPC analysis

The 2D function can quickly detect the printing defects such as offset, less tin, missing printing and connecting tin, and the detection points can be increased arbitrarily; SPC software can ensure the printing quality through the sample analysis machine CPK index collected by the machine.

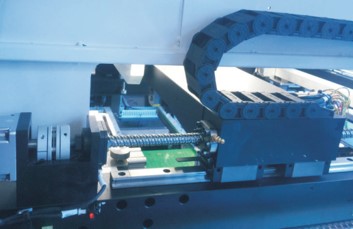

Printing axis servo drive

The scraper Y axis adopts servo motor drive through screw drive,to improve accuracy grade,operational stability and extend the service life,to provide customers with a good printing control platform.

Automatic dispensing function

According to different printing process requirements, after printing, the PCB can be carry out accurate dispensing, tin dispensing,ine drawing, filling and other functional operations.

Provide one-stop SMT assembly production line

Related products

|

|

|

| SMT stencil printer | SMT pick and place machine | Reflow oven NeoDen IN6 |

FAQ

Q1: This is the first time I use this kind of machine, is it easy to operate?

A: We have English user manual and guide video to teach you how to use the machine. If still have question, pls contact us by email / skype / whatapp / phone / trademanager online service.

Q2: Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT Machine, Pick and Place Machine, Reflow Oven, Screen Printer, SMT Production Line and other SMT Products.

Q3: What we can do for you?

A: Total SMT Machines and Solution, professional Technical Support and Service.

About Us

Exhibition

Certification

Our Factory

If you need, please feel free to contact us for more information.

Product detail pictures:

Related Product Guide:

Defect analysis of reflow welding

We insist over the principle of enhancement of 'High high quality, Efficiency, Sincerity and Down-to-earth working approach' to offer you with superb assistance of processing for Pcb Solder Printer – SMT automatic printer screen printing machine – Neoden , The product will supply to all over the world, such as: Bolivia, Bangkok, Ukraine, Our well-equipped facilities and excellent quality control throughout all stages of production enable us to guarantee total customer satisfaction. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact me. We are looking forward to forming successful business relationship with new clients around the world.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.