When building multilayer ceramic capacitors (MLCCs), electrical engineers often choose two types of dielectric depending on the application – Class 1, non-ferroelectric material dielectrics such as C0G/NP0, and Class 2, ferroelectric material dielectrics such as X5R and X7R. The key difference between them is whether the capacitor, with increasing voltage and temperature, still still have good stability. For Class 1 dielectrics, the capacitance remains stable when a DC voltage is applied and the operating temperature rises; Class 2 dielectrics have a high dielectric constant (K), but the capacitance is less stable under changes in temperature, voltage, frequency and over time.

Although the capacitance can be increased by various design changes, such as changing the surface area of the electrode layers, the number of layers, the K value or the distance between the two electrode layers, the capacitance of Class 2 dielectrics will eventually drop sharply when a DC voltage is applied. This is due to the presence of a phenomenon called DC bias, which causes the Class 2 ferroelectric formulations to eventually experience a drop in dielectric constant when a DC voltage is applied.

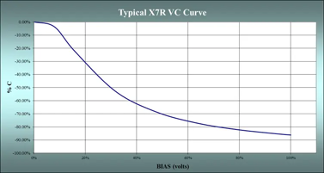

For higher K values of dielectric materials, the effect of DC bias can be even more severe, with capacitors potentially losing up to 90% or more of their capacitance, as shown in the diagram.

The dielectric strength of a material, i.e. the voltage that a given thickness of material can withstand, can also change the effect of DC bias on a capacitor. In the USA, dielectric strength is usually measured in volts/mil (1 mil equals 0.001 inch), elsewhere it is measured in volts/micron, and it is determined by the thickness of the dielectric layer. As a result, different capacitors with the same capacitance and voltage rating may perform significantly differently due to their different internal structures.

It is worth noting that when the applied voltage is greater than the dielectric strength of the material, sparks will pass through the material, leading to a potential ignition or small-scale explosion risk.

Practical examples of how DC bias is generated

If we consider the change in capacitance due to the operating voltage in conjunction with the change in temperature, then we find that the capacitance loss of the capacitor will be greater at the specific application temperature and DC voltage. Take for example an MLCC made of X7R with a capacitance of 0.1µF, a rated voltage of 200VDC, an internal layer count of 35 and a thickness of 1.8 mils (0.0018 inches or 45.72 microns), this means that when operating at 200VDC the dielectric layer only experiences 111 volts/mil or 4.4 volts/micron. As a rough calculation, the VC would be -15%. If the temperature coefficient of the dielectric is ±15%ΔC and the VC is -15%ΔC, then the maximum TVC is +15% – 30%ΔC.

The reason for this variation lies in the crystal structure of the Class 2 material used – in this case barium titanate (BaTiO3). This material has a cubic crystal structure when the Curie temperature is reached or above. However, when the temperature returns to the ambient temperature, polarisation occurs as the lowering of the temperature causes the material to change its structure. Polarisation occurs without any external electric field or pressure and this is known as spontaneous polarisation or ferroelectricity. When a DC voltage is applied to the material at ambient temperature, spontaneous polarisation is linked to the direction of the electric field of the DC voltage and a reversal of the spontaneous polarisation occurs, resulting in a reduction in capacitance.

Nowadays, even with the various design tools available to increase the capacitance, the capacitance of Class 2 dielectrics still decreases significantly when a DC voltage is applied due to the presence of the DC bias phenomenon. Therefore, in order to ensure the long-term reliability of your application, you need to take into account the effect of DC bias on the component in addition to the nominal capacitance of the MLCC when selecting an MLCC.

Zhejiang NeoDen Technology Co., LTD., founded in 2010, is a professional manufacturer specialized in SMT pick and place machine, reflow oven, stencil printing machine, SMT production line and other SMT Products. We have our own R & D team and own factory, taking advantage of our own rich experienced R&D, well trained production, won great reputation from the world wide customers.

We believe that great people and partners make NeoDen a great company and that our commitment to Innovation, Diversity and Sustainability ensures that SMT automation is accessible to every hobbyist on everywhere.

Post time: May-05-2023