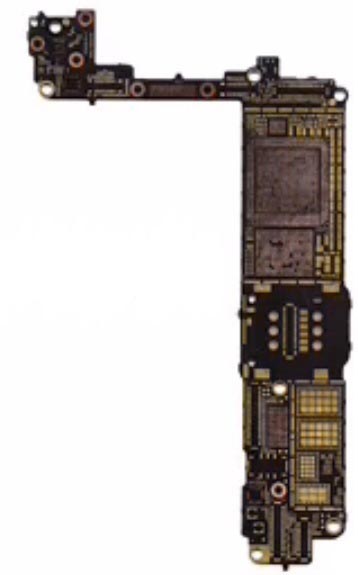

In recent years, with the increase in the performance requirements of smart terminal devices such as smart phones and tablet computers, the SMT manufacturing industry has a stronger demand for miniaturization and thinning of electronic components. With the rise of wearable devices, this demand is even greater. Increasingly. The picture below is a comparison of I-phone 3G and I-phone 7 motherboards. The new I-phone mobile phone is more powerful, but the assembled motherboard is smaller, which requires smaller components and more dense components. Assembly can be done. With smaller and smaller components, it will become more and more difficult for our production process. The improvement of a through rate has become the main goal of SMT process engineers. Generally speaking, more than 60% of the defects in the SMT industry are related to solder paste printing, which is a key process in SMT production. Solving the problem of solder paste printing is equivalent to solving most of the process problems in the entire SMT process.

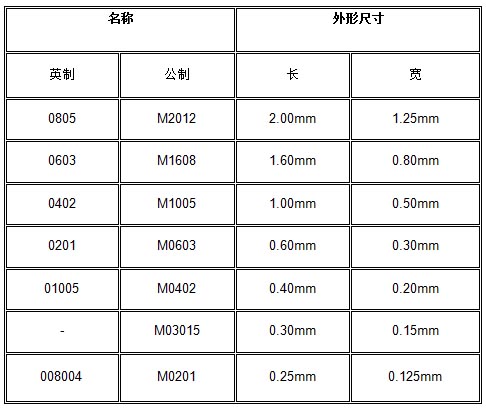

The figure below is a comparison table of metric and imperial dimensions of SMT components.

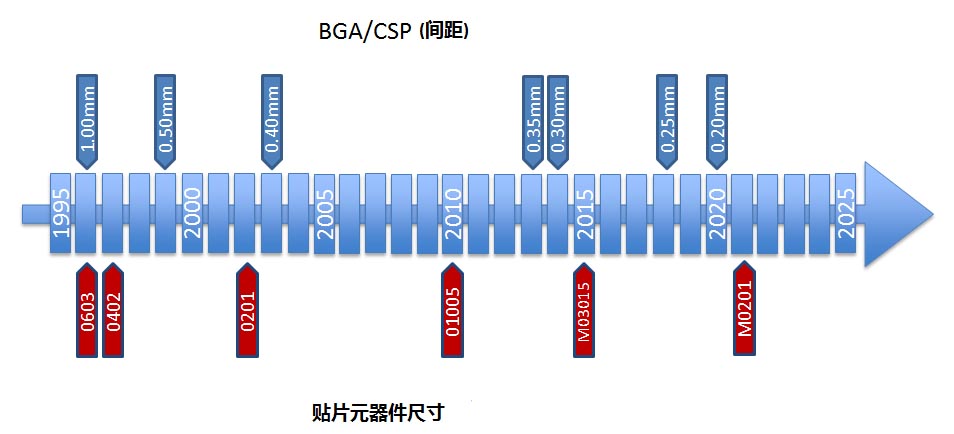

The following figure shows the development history of SMT components and the development trend looking forward to the future. At present, British 01005 SMD devices and 0.4 pitch BGA/CSP are commonly used in SMT production. A small number of metric 03015 SMD devices are also used in production, while metric 0201 SMD devices are currently only in the trial production stage and are expected to be gradually used in production in the next few years.

Post time: Aug-04-2020