News

-

Placing machine six components

Generally we use the SMT machine is composed of six parts, the following is a brief explanation for you: Working table: It is used as the basic components for the production, installation and support of the mount machine. Therefore, it must have sufficient support strength. If the support streng...Read more -

How to prevent the SMT machine failure

We are often used in the processing production pick and place machine, SMT machine belongs to the intelligent machine, more useful, but because of the production process, we not appropriate to use, easy to cause machine damage or malfunction, so in order to avoid we need to give the machine to av...Read more -

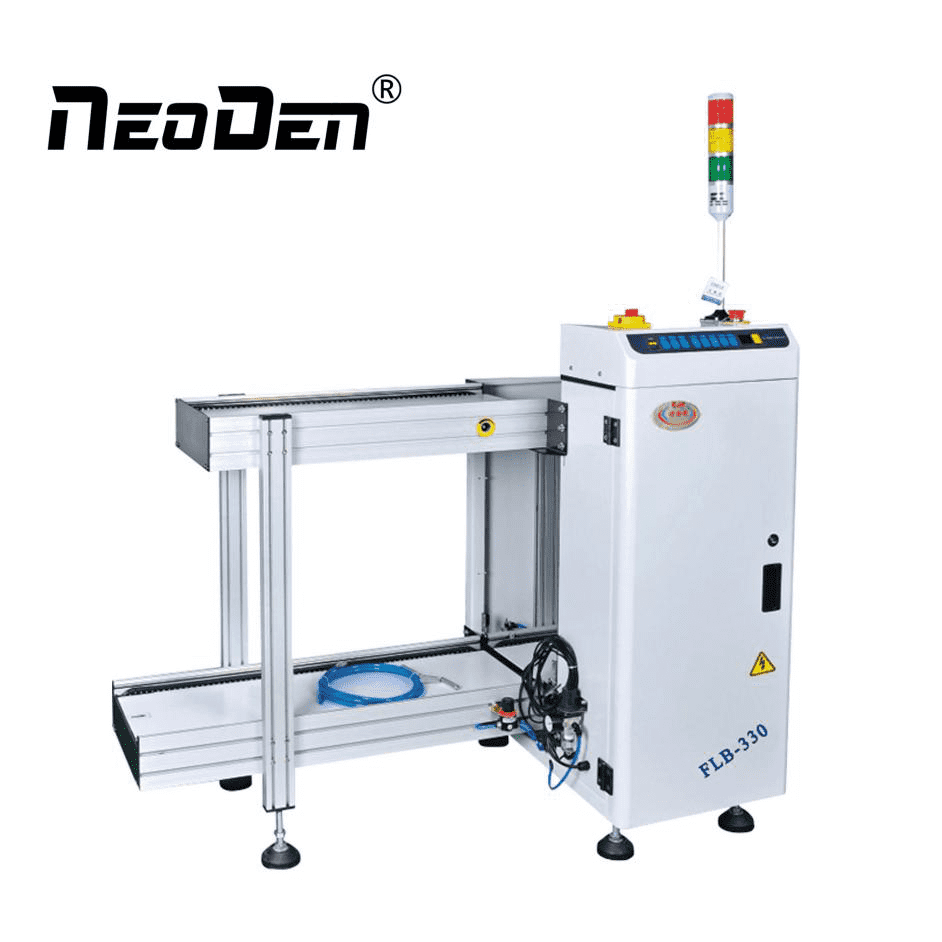

The function and operation flow of SMT loader

The role of SMT loader SMT PCB loader is a kind of production equipment needed in SMT production line. Its main function is to put the unattached PCB board in the SMT plate mounting machine and automatically feed the board to the suction plate machine. Then the suction plate machine will automati...Read more -

NeoDen Holiday Notice

Read more -

Common fault analysis and solution of SMT Feeder

During SMT production, SMT machine often encounter some problems, which affect the efficiency and productivity of the patch. In the patch production, SMT Feeder is the most common part with problems. The following to help you analyze the common failures and solutions of the SMT machine, We hope t...Read more -

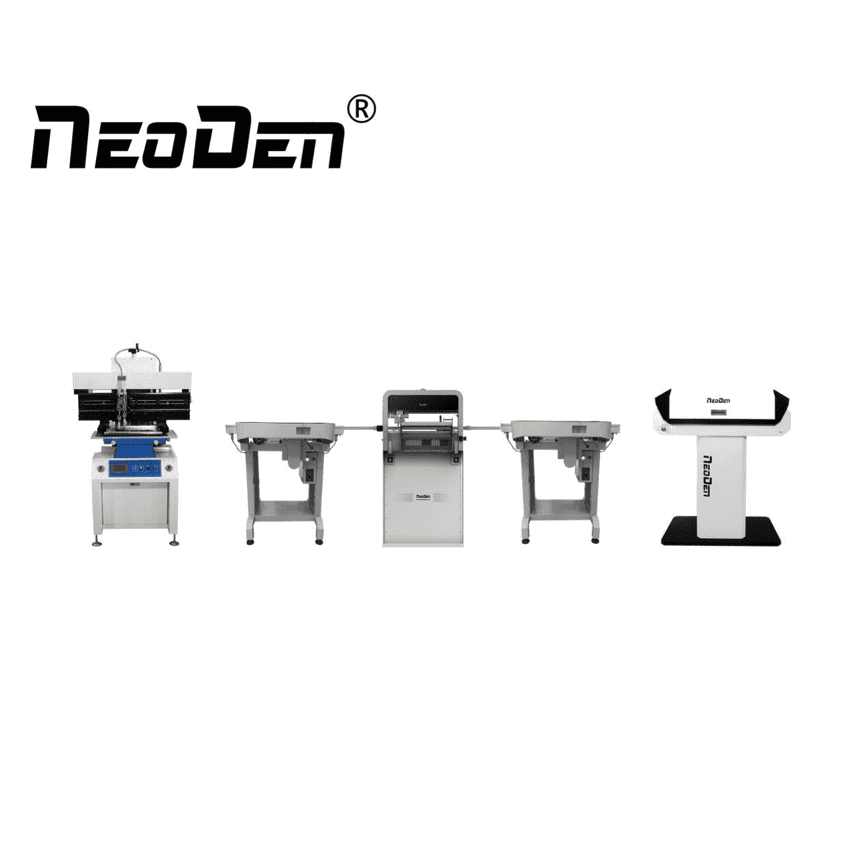

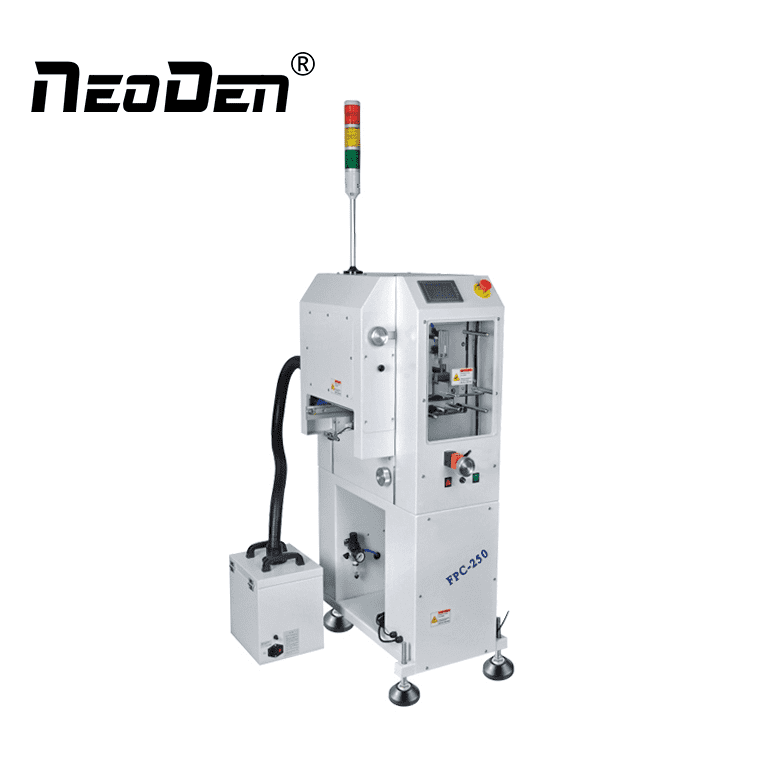

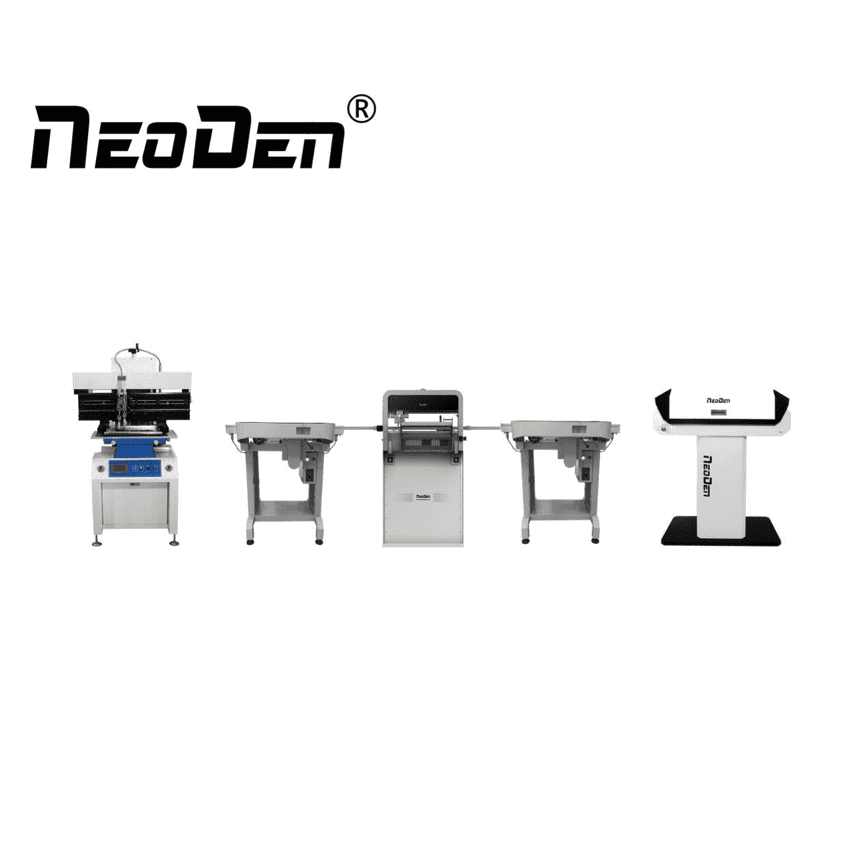

Neoden PCB automatic production line introduction

PCB loader 1、Solid and stable design. 2、PLC control system. 3、Light touch LED membrane switch or touch screen control panel 4、options available 5、Top and bottom pneumatic clamps to secure magazine rack 6、Pressure regulated on pusher’s to prevent board damage 7、Self diagnostic error code d...Read more -

Composition of SMT production line

SMT production lines can be divided into automatic production lines and semi-automatic production lines according to the degree of automation, and can be divided into large, medium and small production lines according to the size of the production line. Fully automatic production line is refers...Read more -

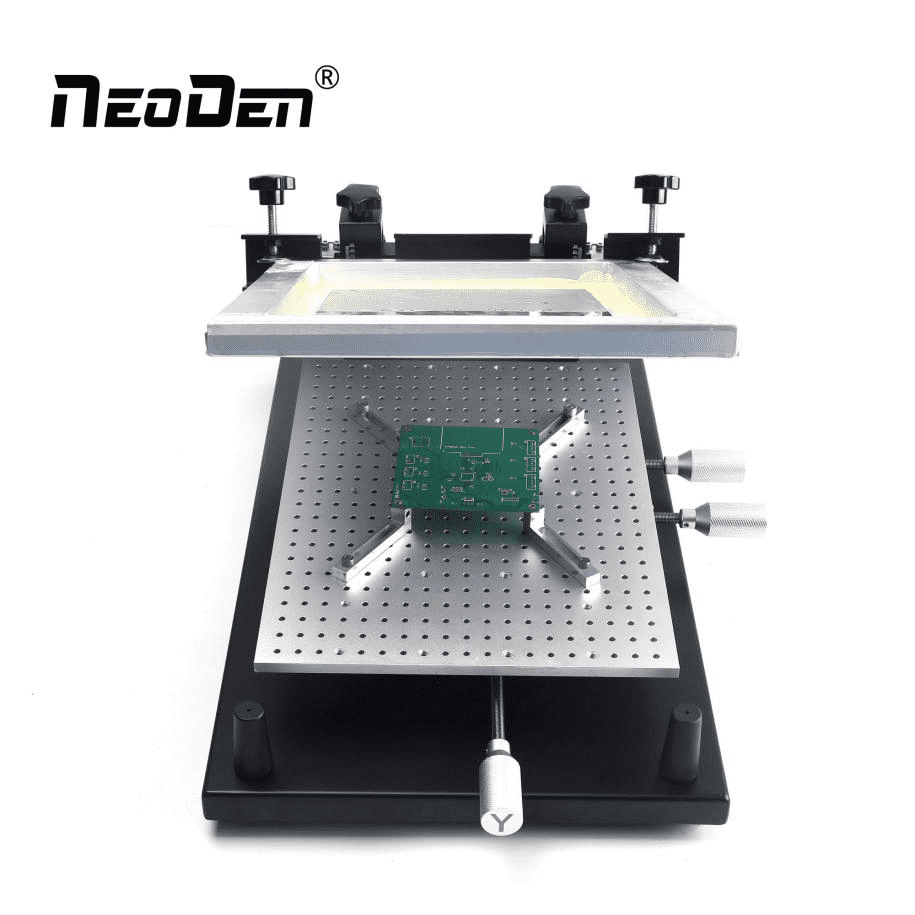

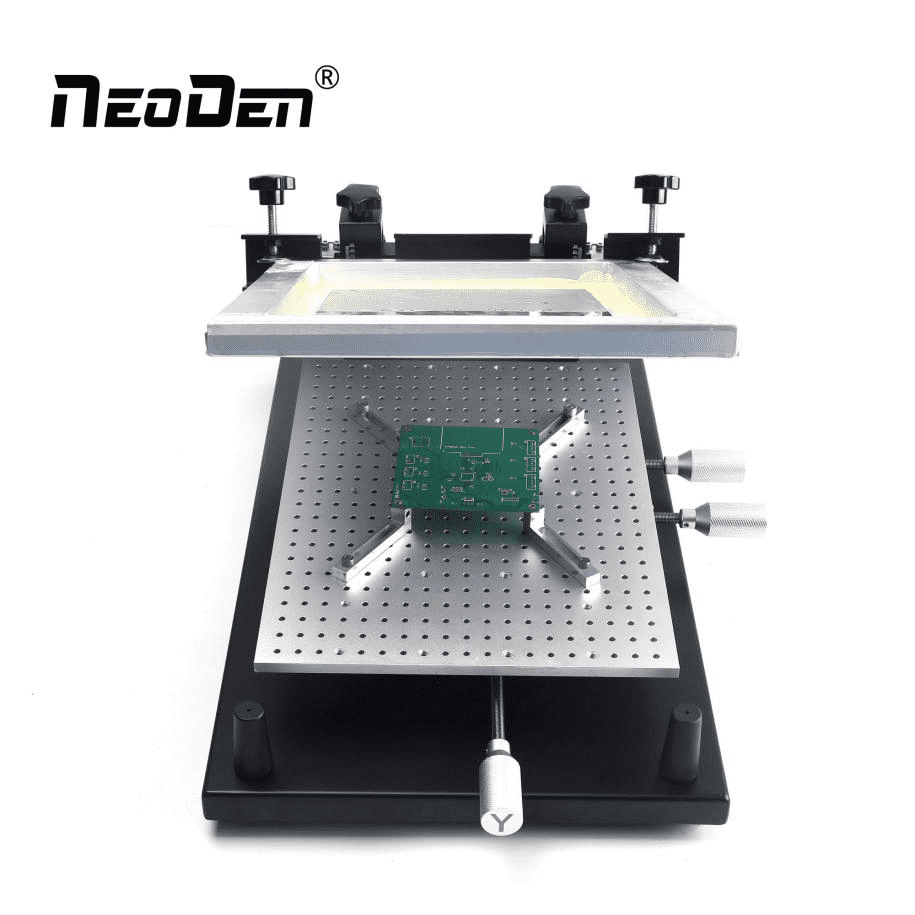

Suggestions on the operation of manual solder printer

Placing and positioning of manual solder printer In SMT production line, printing is to slip the solder paste onto the corresponding pads on the PCB to prepare for the next patch. Manual solder printer refers to the process of manually printing solder paste using a manual printing machine. The o...Read more -

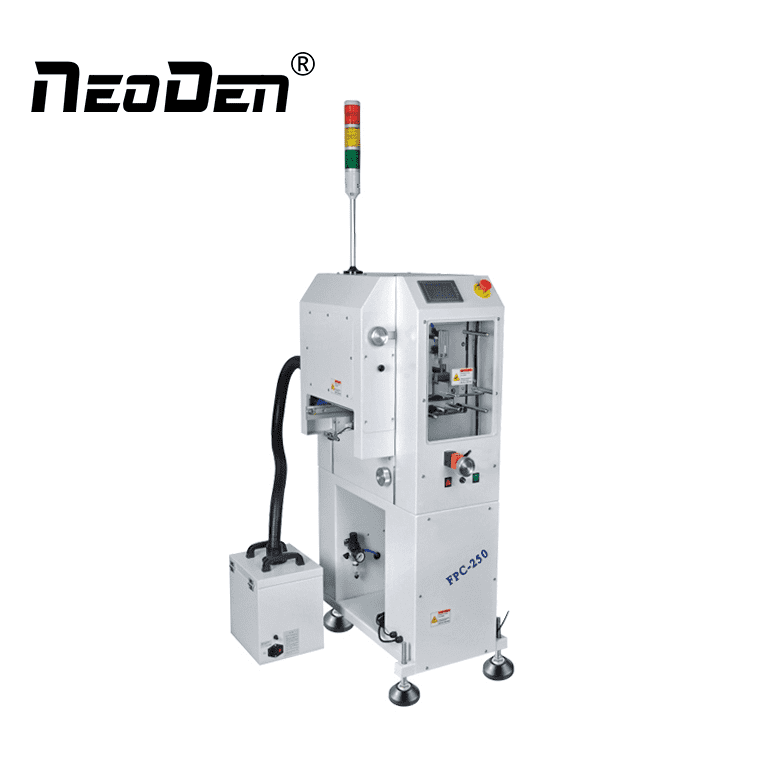

Advantages of AOI and manual inspection

AOI machine is the automatic optical detector, which uses the optical principle to scan the camera on the device for PCB, collect images, compare the collected solder joint data with the qualified data in the machine database, and mark the defective PCB welding after image processing. AOI has gre...Read more -

Configuration of Full-automatic visual printer

We are manufactory product different types of solder printers. Here is some configurations of Full-Automatic Visual Printer. Standard Configuration Accurate optical positioning system: Four way light source is adjustable, light intensity is adjustable, light is uniform, and image acquisition is m...Read more -

PCB cleaning machine role

PCB cleaning machine can replace artificial cleaning PCB, along with the increase of the efficiency and ensure the cleaning quality, than the artificial cleaning more convenient, shortcut, PCB cleaning machine to clean the residual flux through solution, tin beads, dark dirty mark, and so on some...Read more -

AOI classification and structure principle in SMT production

With the wide application of 0201 chip components and 0.3 Pinch integrated circuit, enterprises have higher and higher requirements for product quality, which cannot be guaranteed by visual inspection alone. At this time, AOI technology arises at the right moment. As a new member of SMT productio...Read more