News

-

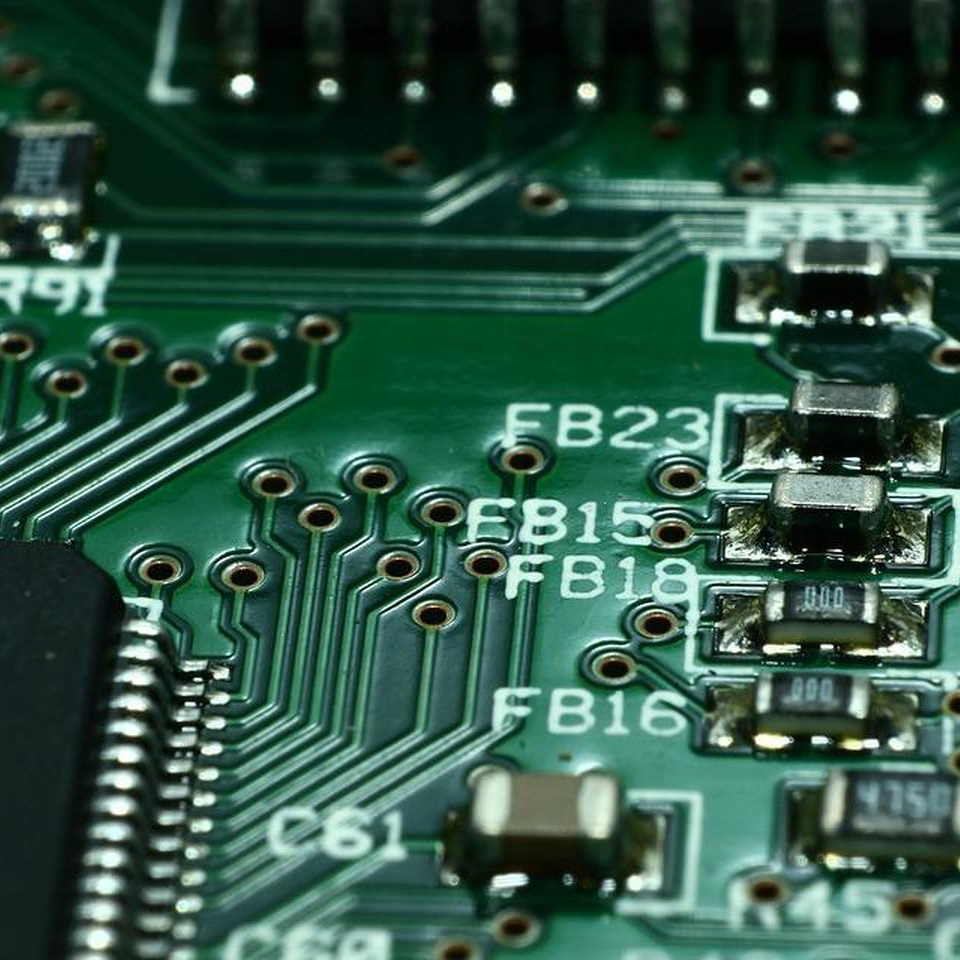

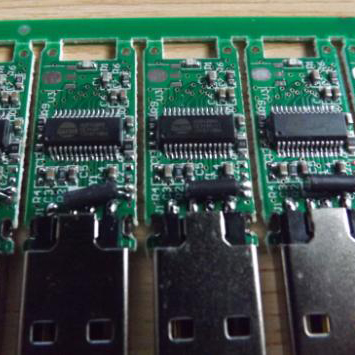

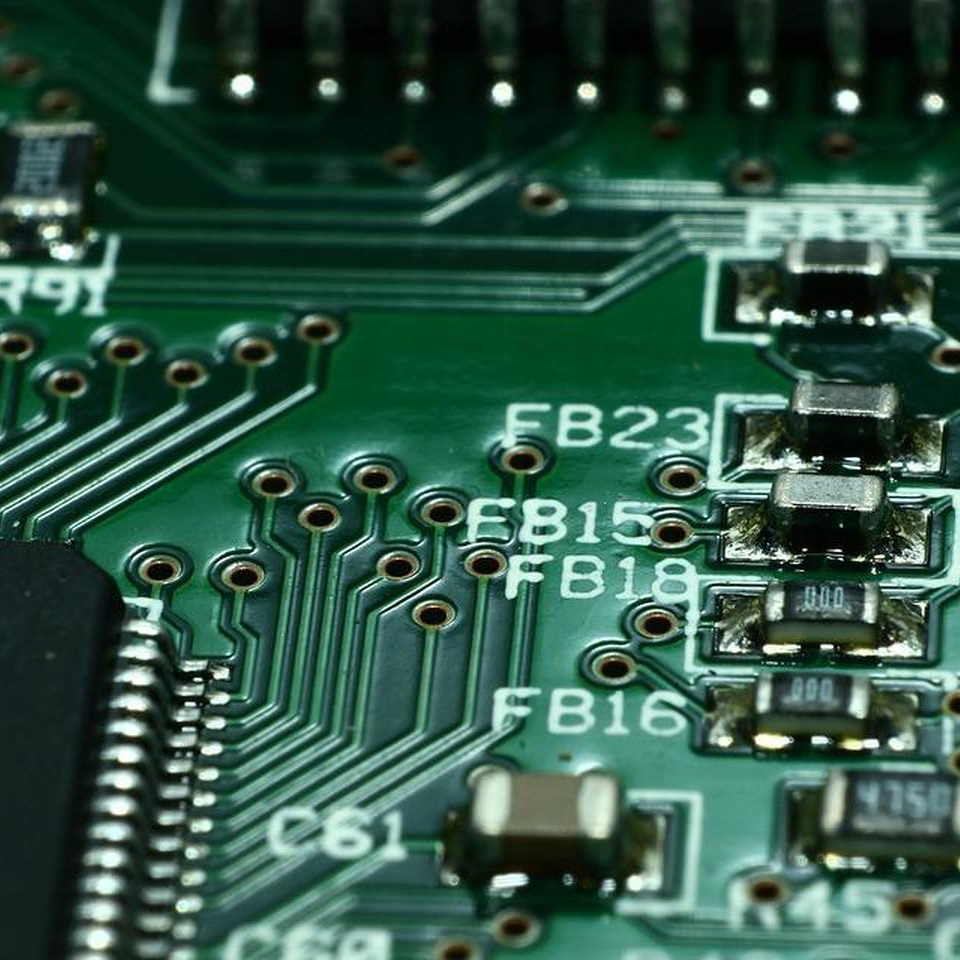

Four Types of SMT Equipment

SMT equipment, commonly known as SMT machine. It is the key equipment of surface mount technology, and it has many models and specifications, including large, medium and small. Pick and place machine is divided into four types: assembly line SMT machine, simultaneous SMT machine, sequential SMT m...Read more -

What Is The Role of Nitrogen in Reflow Oven?

SMT reflow oven with nitrogen (N2) is the most important role in reducing the welding surface oxidation, improve the wettability of welding, because nitrogen is a kind of inert gas, not easy to produce compounds with metal, it can also cut off the oxygen in the air and metal contact at high tempe...Read more -

How to Store PCB Board?

1. after the production and processing of PCB, vacuum packaging should be used for the first time. There should be desiccant in the vacuum packaging bag and the packaging is close, and it can not contact with water and air, so as to avoid the soldering of reflow oven and product quality affected ...Read more -

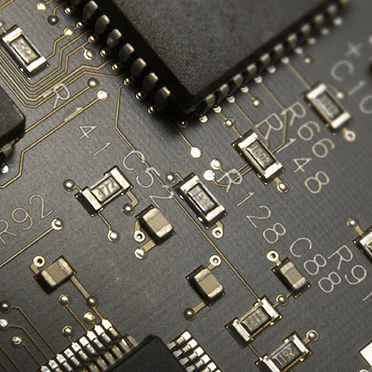

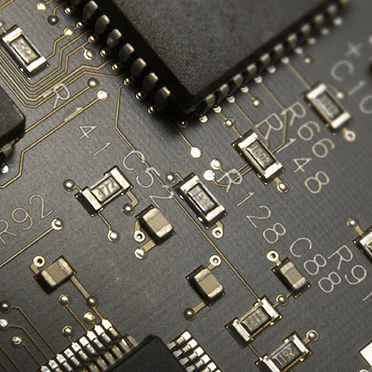

What Are The Causes of Chip Component Cacking?

In the production of PCBA SMT machine, the cracking of chip components is common in the multilayer chip capacitor (MLCC), which is mainly caused by thermal stress and mechanical stress. 1. The STRUCTURE of MLCC capacitors is very fragile. Usually, MLCC is made of multi-layer ceramic capacitors, s...Read more -

Precautions for PCB Welding

1. Remind everyone to check the appearance first after getting the PCB bare board to see whether there is short circuit, circuit break and other problems. Then get familiar with the development board schematic diagram, and compare the schematic diagram with the PCB screen printing layer to avoid ...Read more -

What Is The Importance of Flux?

NeoDen IN12 reflow oven Flux is an important auxiliary material in PCBA circuit board welding. The quality of flux will directly affect the quality of reflow oven. Let’s analyze why flux is so important. 1. flux welding principle Flux can bear the welding effect, because the metal atoms are...Read more -

Causes of Damage-Sensitive Components (MSD)

1. The PBGA is assembled in the SMT machine, and the dehumidification process is not carried out before welding, resulting in the damage of PBGA during welding. SMD packaging forms: non-airtight packaging, including plastic pot-wrap packaging and epoxy resin, silicone resin packaging (exposed to ...Read more -

What Is The Difference between SPI and AOI?

The main difference between SMT SPI and AOI machine is that SPI is a quality check for paste presses after stencil printer printing, through the inspection data to solder paste printing process debugging, verification and control; SMT AOI is divided into two types: pre-furnace and post-furnace. T...Read more -

SMT Short Circuit Causes and Solutions

Pick and place machine and other SMT equipment in the production and processing will appear a lot of bad phenomena, such as monument, bridge, virtual welding, fake welding, grape ball, tin bead and so on. SMT SMT processing short circuit is more common in fine spacing between IC pins, more common...Read more -

What’s The Difference Between Reflow and Wave Soldering?

NeoDen IN12 What is reflow oven? Reflow soldering machine is to melt the solder paste pre-coated on the solder pad by heating to realize the electrical interconnection between the pins or welding ends of electronic components pre-mounted on the solder pad and the solder pad on the PCB, so as to a...Read more -

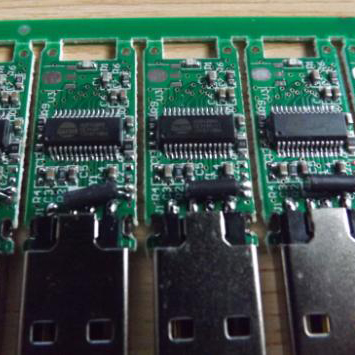

How Much Does A Pick and Place Machine Cost?

The amount of automatic pick and place machine depends mainly on the following factors: 1. Origin of SMT machine There is probably several times the price difference between the automatic surface mount machine made in China and that made in other countries. The price of other countries’ aut...Read more -

The Only Mainland Chinese SMT Brand to be Listed on Wikipedia——NeoDen!

We are very happy that NeoDen can be included in Wikipedia and become the only pick and place machine brand included in mainland China! This is the affirmation of our company’s products and the trust of our NeoDen brand. We will also continue to provide SMT enthusiasts with better quality ...Read more