News

-

Six Methods of SMT Patch Component Disassembly(I)

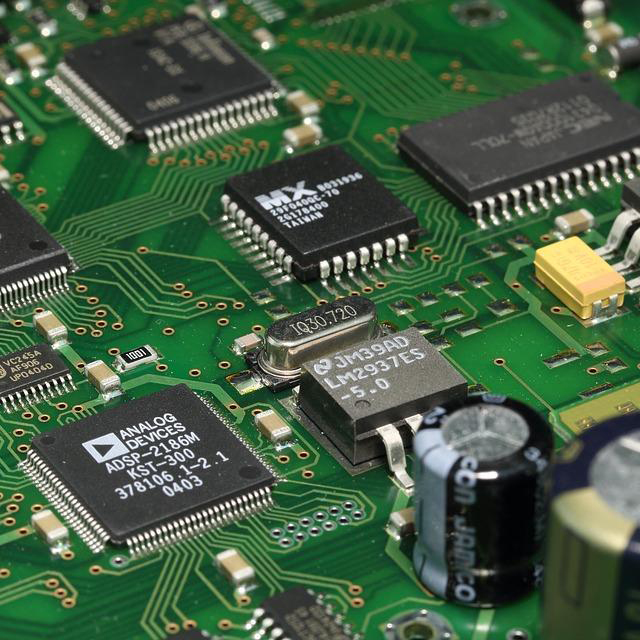

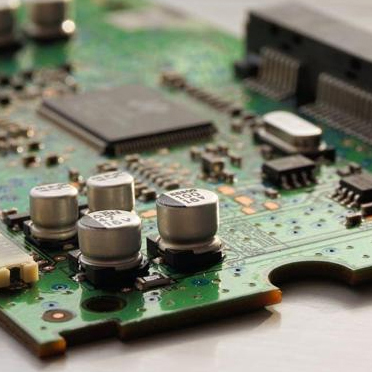

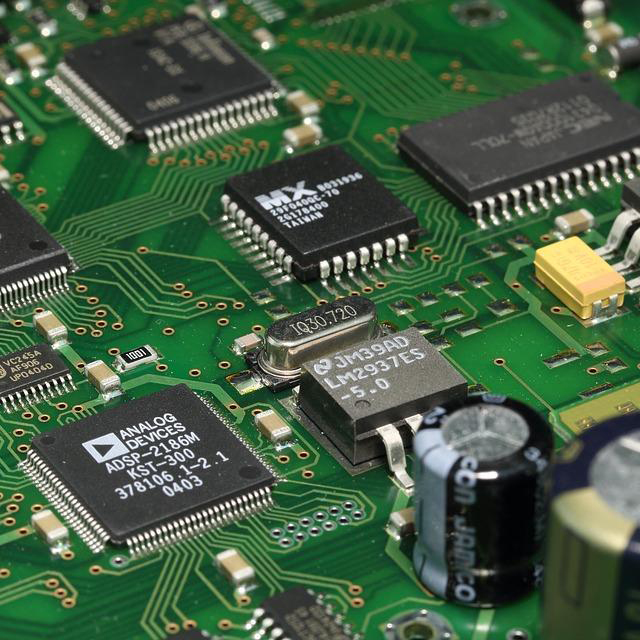

Chip components are small and micro components without leads or short leads, which are directly installed on PCB and are special devices for surface assembly technology. Chip components have the advantages of small size, light weight, high installation density, high reliability, strong seismic re...Read more -

How to Reduce Material throwing Rate in SMT Production Line?

I. In order to eliminate SMT machine production process of high material throwing rate, it can not ignore the human factors, such as the common cause of high material throwing rate of the operation is the operator when the installation of material tearing belt is too long and too much pressure, t...Read more -

Knowledge of SMT Steel Mesh

NeoDen Stencil Printer YS350 SMT steel mesh is used for the liquid and solid state of solder paste printing on the PCB board, circuit board in addition to the power board most popular now use SMT technology, there are many table paste bonding pad on the PCB, namely without hole welding way, and t...Read more -

What Are the Key Processes of Reflow Oven?

SMT pick and place machine refers to the abbreviation of a series of technological processes on the basis of PCB. PCB means a Printed Circuit Board. Surface Mounted Technology is the most popular Technology and process in the electronic assembly industry at present. Printed Circuit Board is a Ci...Read more -

Differentiation method of medium speed and high speed SMT machine

SMT mount machine is a key equipment in SMT production line, mainly used for electronic products. Pick and place machine according to the actual production needs, their speed is different, it can be divided into ultra-high speed mounting machine, high speed mounting machine, medium speed mounting...Read more -

What are the indicators of SMT machine precision?

Pick and place machine SMT line equipment, SMT machine is the most core, the most critical equipment, generally occupy more than 60% of the cost of the whole line. Choose pick and place machine, many people will ask the accuracy of SMT machine this important parameter index. The precision of the ...Read more -

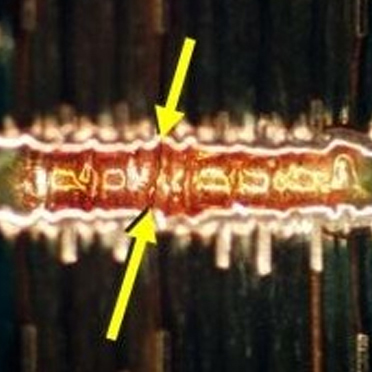

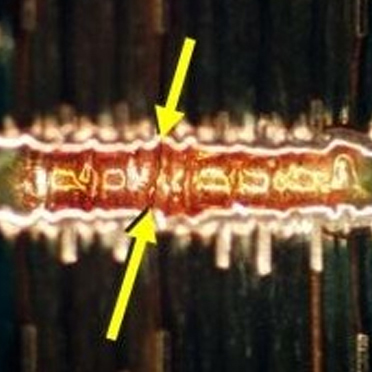

What is the cause of corrosion on the surface of PCBA?

After PCBA welding, there will be residues of tin, flux, dust and employees’ fingerprints on the surface of the PCBA board, leading to the surface of the PCBA board is dirty, and the organic acids and electric ions in the flux residue will cause corrosion and short circuit on the PCBA board...Read more -

What Will Happen If the PCB Material and Size Are not Suitable?

1. According to provisions of GJB3835, after warping and deformation welding of PCBA in reflow oven welding process, the maximum warping and distortion shall not exceed 0.75%, and the warping and distortion of PCB with fine-spacing components shall not exceed 0.5%. 2. PCBA with obvious warping, i...Read more -

Performance Advantages of Small reflow Oven

Small reflow oven machine has its own price and quality advantages, but also has the advantages of energy saving and environmental protection. In fact, SMT reflow oven is a very good alternative to small electronics factories. Let’s talk about the performance advantages of NeoDen reflow sol...Read more -

How to maintain and check SMT suction nozzle

SMT suction Nozzle is the main component of SMT pick and place machine, daily maintenance and cleaning of it is very important. Now Neoden SMT machine factory will tell you how to maintain the suction nozzle of the pick and place machine, please see the following: 1. Wipe the surface of SMT nozz...Read more -

What are the factors that affect the efficiency of SMT machine

Pick and place machine should not only be fast, but also accurate and stable. In the actual operation process, each mount electronic components specifications are different, the speed is not the same. For example, the accuracy of LED components is relatively low relative to the accuracy requireme...Read more -

Name and function of each component of the SMT

1. Host 1.1 Main Power Switch: turn on or off the mainframe Power 1.2 Vision Monitor: Displaying the recognition of images or components and marks obtained by the moving lens. 1.3 Operation Monitor: The VIOS software screen that displays the Operation of the SMT machine. If there is an error or p...Read more