News

-

The 4 Characteristics of Radio-frequency Circuits

This article explains the 4 basic characteristics of RF circuits from four aspects: RF interface, small expected signal, large interference signal, and interference from adjacent channels, and gives important factors that need special attention in the PCB design process. RF circuit simulation of ...Read more -

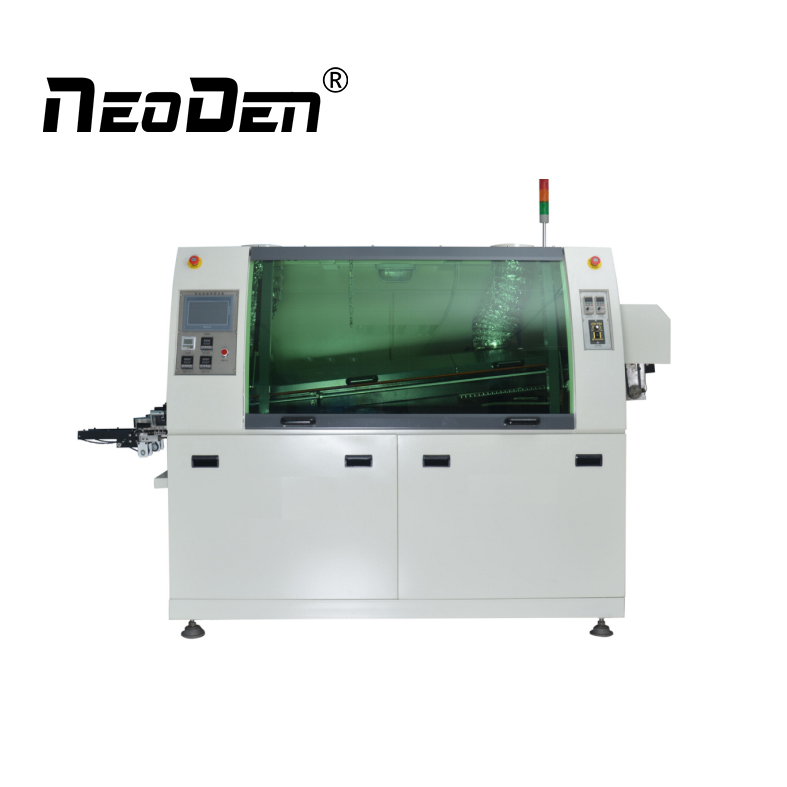

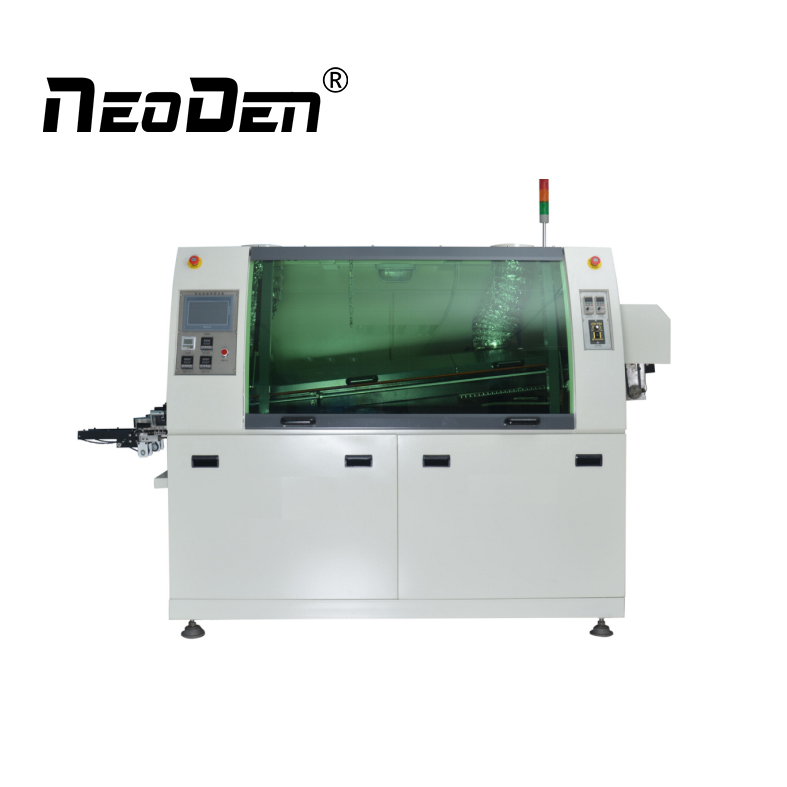

The Main Points of Wave Soldering Operation

I. Wave soldering machine temperature control Refers to the nozzle outlet temperature of the solder wave. General temperature control at 230 – 250 ℃, the temperature is too low will make the solder joint rough, pull, not bright. Even cause false solder, false solder; temperature is too high...Read more -

Workflow of Wave Soldering Machine

1. Spray no-clean flux to the circuit board Has been inserted into the completed components of the circuit board, it will be embedded in the jig, from the machine at the entrance of the splicing device to a certain angle of inclination and transmission speed into the wave soldering machine, and t...Read more -

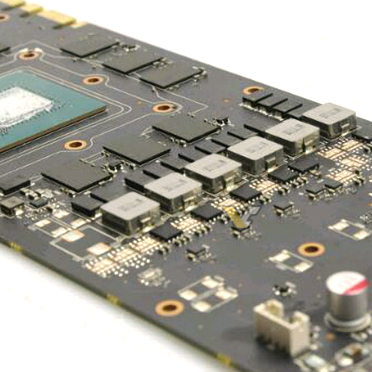

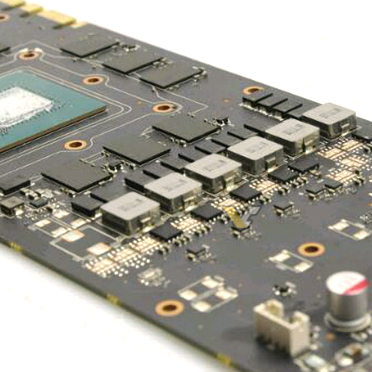

What Does A SMT X-ray Machine Do?

Application of SMT X-ray inspection machine - Testing Chips The purpose and method of chip testing The main purpose of chip testing is to detect factors affecting product quality in the production process as early as possible and to prevent out-of-tolerance batch production, repair and scrap. Thi...Read more -

What Are Some Common PCB Dsign Mistakes?

As an integral part of all electronic devices, the world’s most popular technologies require perfect PCB design. However, the process itself is sometimes anything but. Sophisticated and complex, errors often occur during the PCB design process. As board rework can lead to production delays,...Read more -

What Is Buried Capacitor?

Buried capacitor process The so-called buried capacitance process, is a certain capacitive material using a certain process method embedded in the ordinary PCB board in the inner layer of a processing technology. Because the material has a high capacitance density, so the material can play a powe...Read more -

Maintenance of Selective Wave Soldering Equipment

Maintenance of selective wave soldering machine For selective wave soldering equipment, there are generally three maintenance modules: flux spraying module, preheating module, and soldering module. 1. Flux spraying module maintenance and maintenance Flux spraying is selective for each solder join...Read more -

SMT Production Auxiliary Materials of Some Common Terms

In the SMT placement production process, it is often necessary to use SMD adhesive, solder paste, stencil and other auxiliary materials, these auxiliary materials in the SMT whole assembly production process, the product quality, production efficiency plays a vital role. 1. Storage period (Shelf ...Read more -

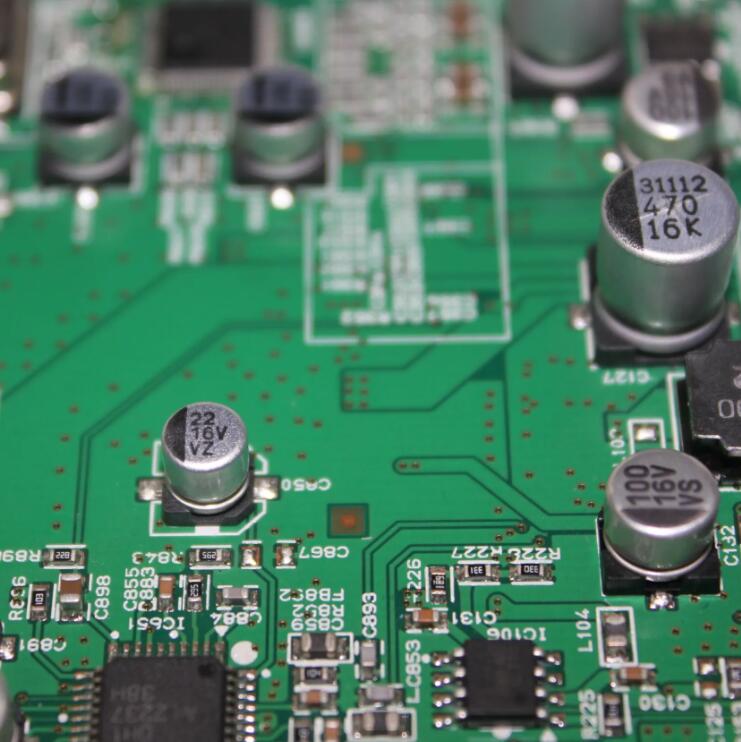

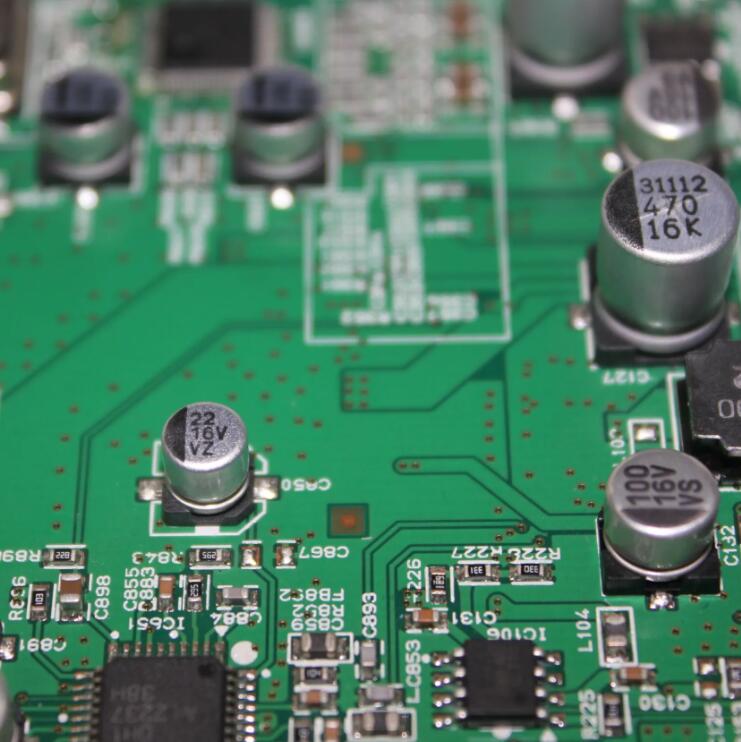

What Conditions Should A Qualified PCB Meet?

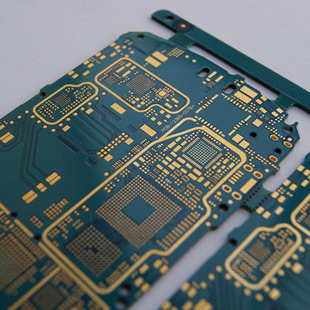

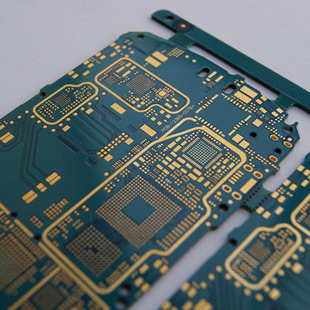

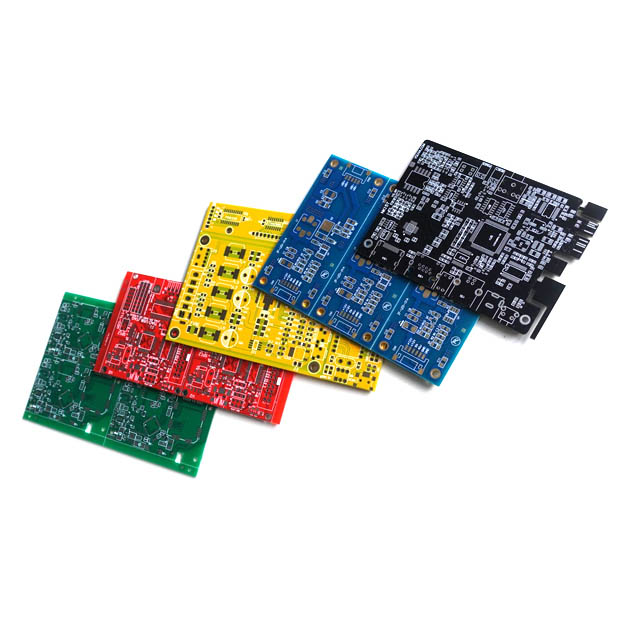

In SMT processing, PCB substrates before the start of processing, the PCB will be checked and tested, selected to meet the SMT production requirements of the PCB, and the unqualified returned to the PCB supplier, the specific requirements of the PCB can be referred to IPc-a-610c International Gen...Read more -

What to Pay Attention to When Designing PCBA Circuit Boards?

1. Standard components should pay attention to the size tolerance of different manufacturers’ components, non-standard components must be designed in accordance with the actual size of the components pad graphics and pad spacing. 2. The design of high-reliability circuit should be widened s...Read more -

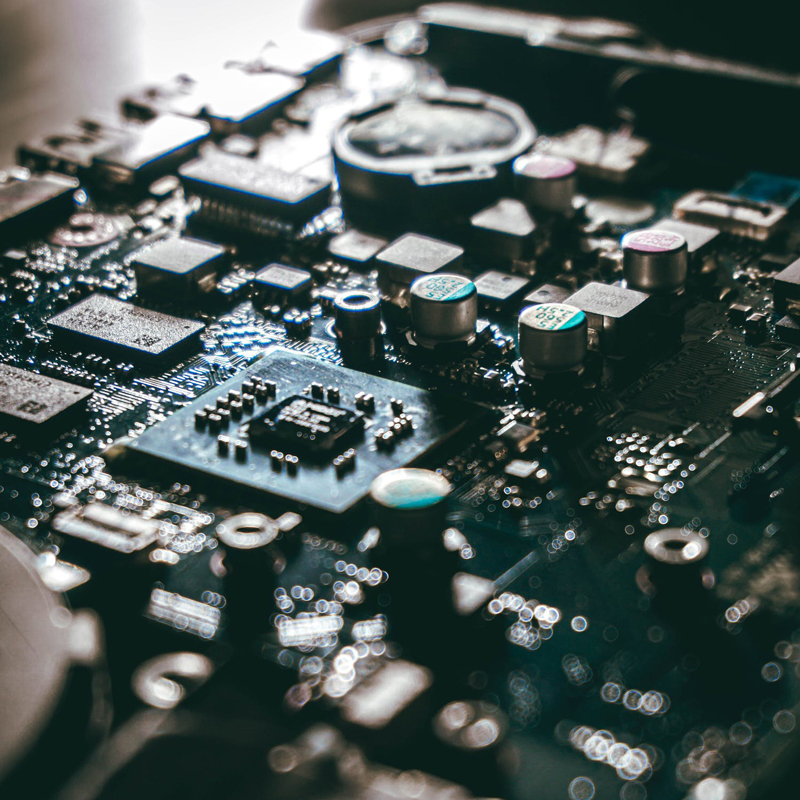

PCBA Process Control and Quality Control of The 6 Major Points

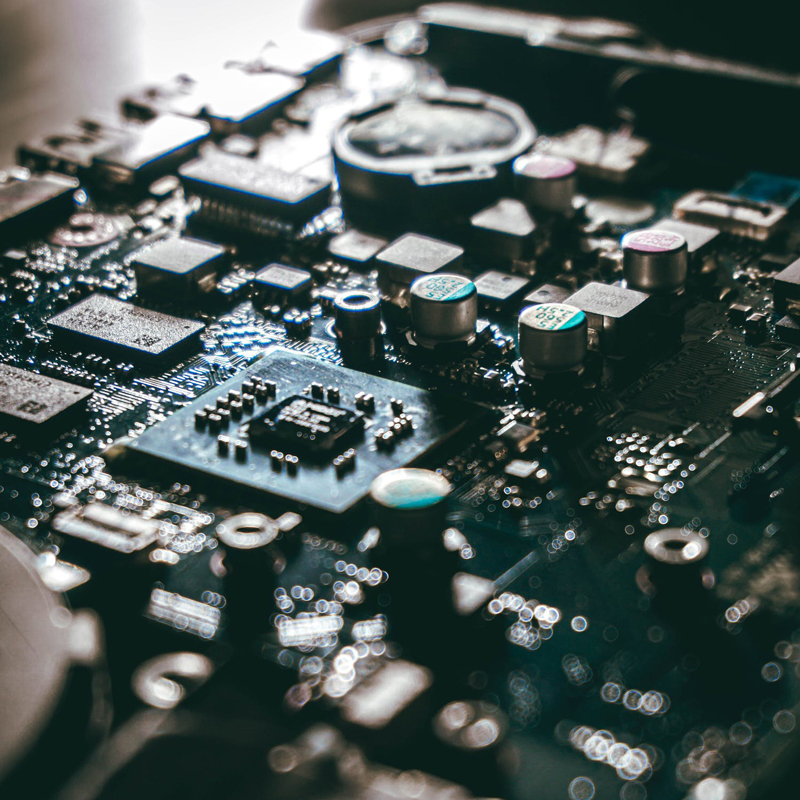

PCBA manufacturing process involves PCB board manufacturing, component procurement and inspection, chip processing, plug-in processing, program burn-in, testing, aging and a series of processes, supply and manufacturing chain is relatively long, any defect in one link will cause a large number of...Read more -

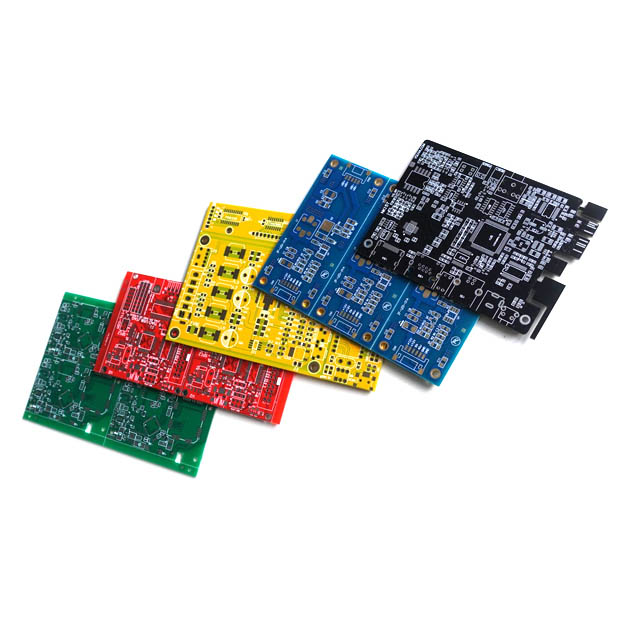

PCB Board Substrate Material Classification

Many varieties of substrates used for PCBs, but broadly divided into two categories, namely inorganic substrate materials and organic substrate materials. Inorganic substrate materials Inorganic substrate is mainly ceramic plates, ceramic circuit substrate material is 96% alumina, in the case of ...Read more