News

-

What are the key points of PCB wiring when anti-surge?

I. Pay attention to the size of the inrush current designed in the PCB wiring In the test, often encounter the original design of the PCB can not meet the needs of the surge. General engineers design, only take into account the functional design of the system, such as the actual work of the syste...Read more -

Sequence of SMT and DIP

PCBA manufacturing and processing industry has two terminology terms: SMT and DIP. The general industry also called these two sections for the front and back, SMT mount in the front, DIP in the back, why the manufacturing process to be so divided? Follow the “first small, then large, first ...Read more -

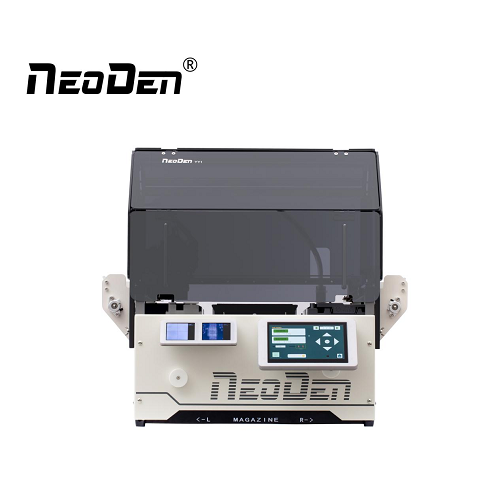

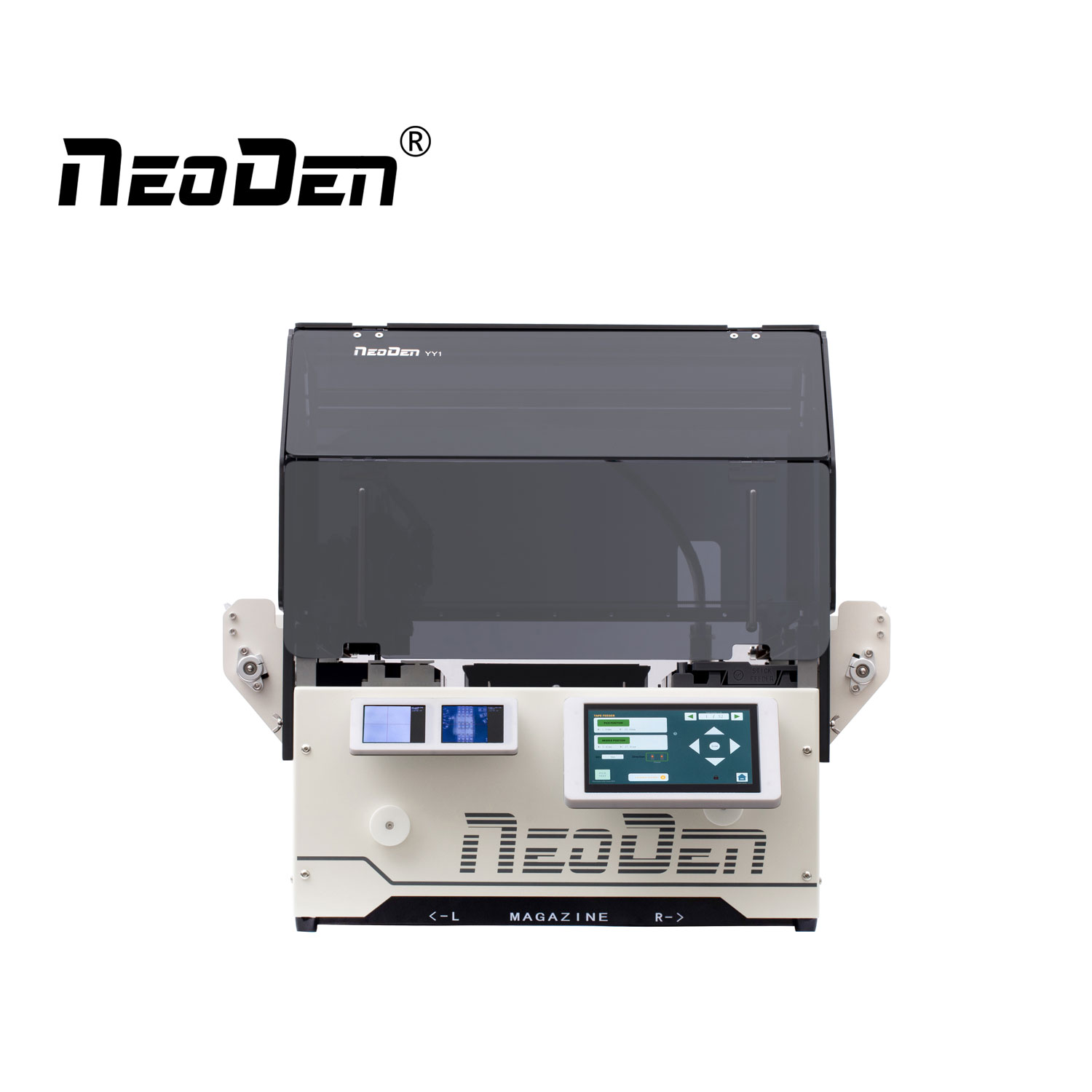

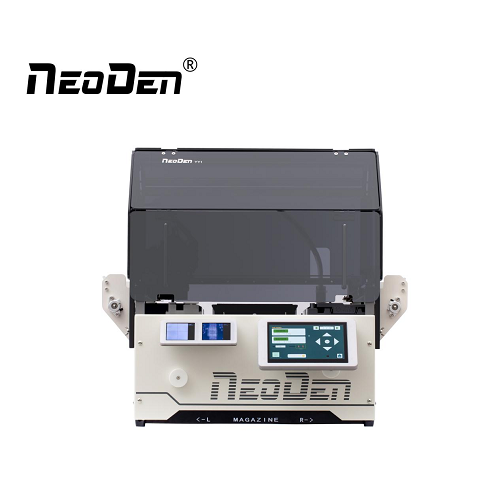

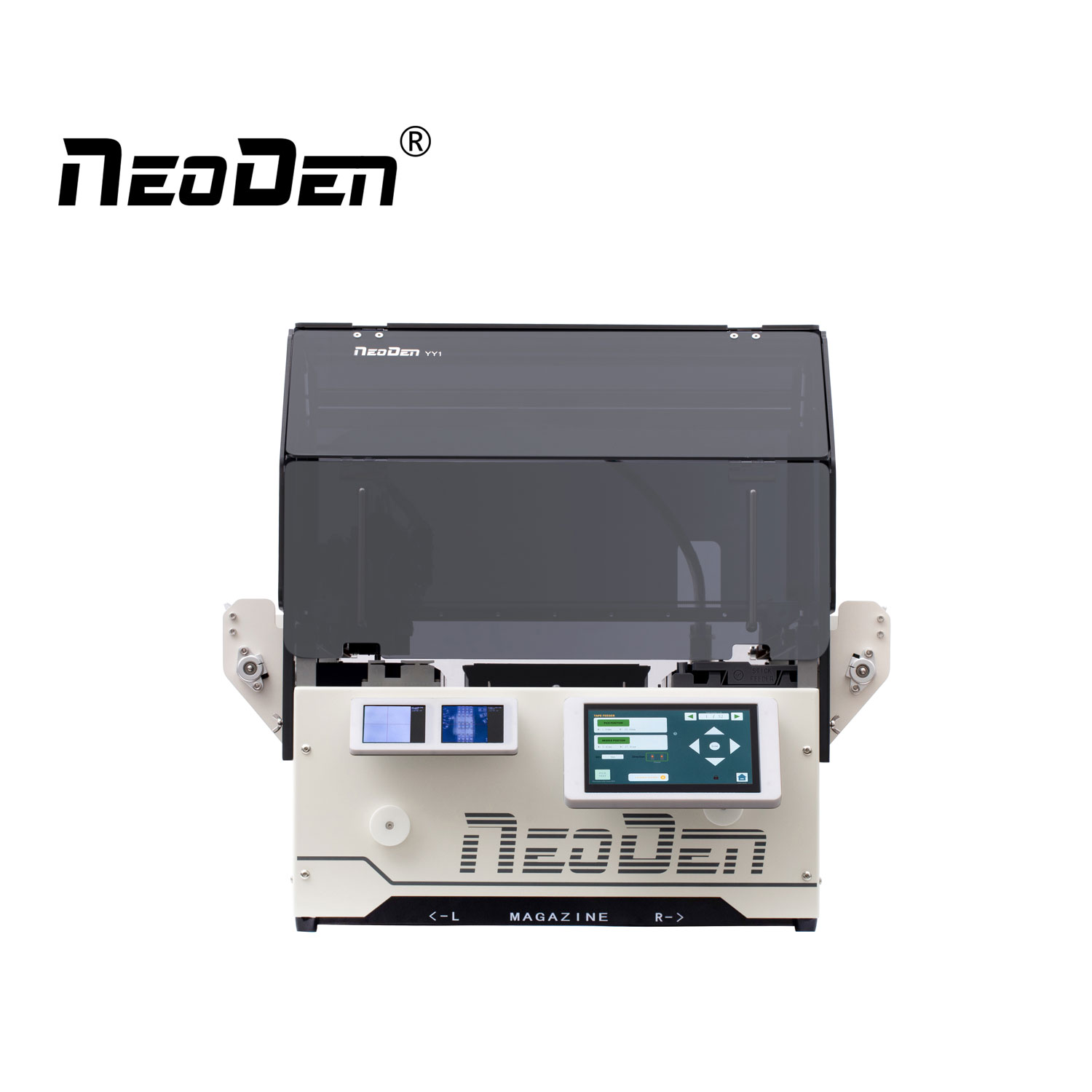

Our New Product NeoDen YY1 Pick and Place Machine Is on Hot Sale!

Why it’s called YY1? NeoDen YY1 pick and place machine would be as easy as a yo-yo that everyone could master it easily. What are the YY1’s Features? 1. Brand new patented peeling gadget. 2. Patented needle module. 3. Dual vision system with built-in IC. 4. Auto nozzle changer. 5. Support Flexi...Read more -

DIP Wave Soldering Machine Process Flow

1. Plug-in There are AI automatic plug-in machine, but also manual plug-in, mainly some high, large points, the need for through-hole capacitors, resistors, inductors 2. Wave soldering machine After the completion of the plug-in, the need to go through the wave soldering, through-hole components ...Read more -

Notes during the operation of the SMT machine

SMT machine is the most critical and core equipment of SMT assembly line. Whether the normal work of the pick and place machine directly affects the operation of the production line of the patching plant, so in the usual production process, must be diligent maintenance, so that the SMT machine to...Read more -

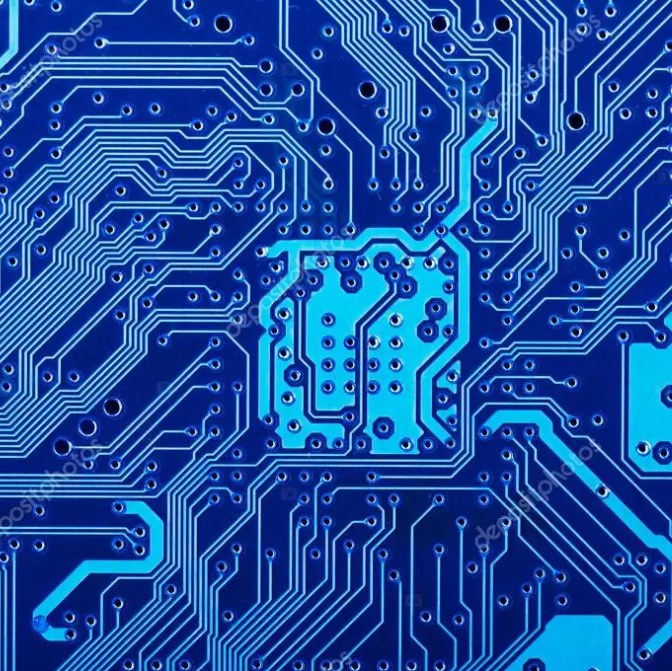

What Are The Components of PCB?

1. Pads. The pad is the metal hole used to solder the pins of the components. 2. Layer. Circuit board according to the design of the different, there will be double-sided, 4-layer board, 6-layer board, 8-layer board, etc., the number of layers are generally double, in addition to go signal layer,...Read more -

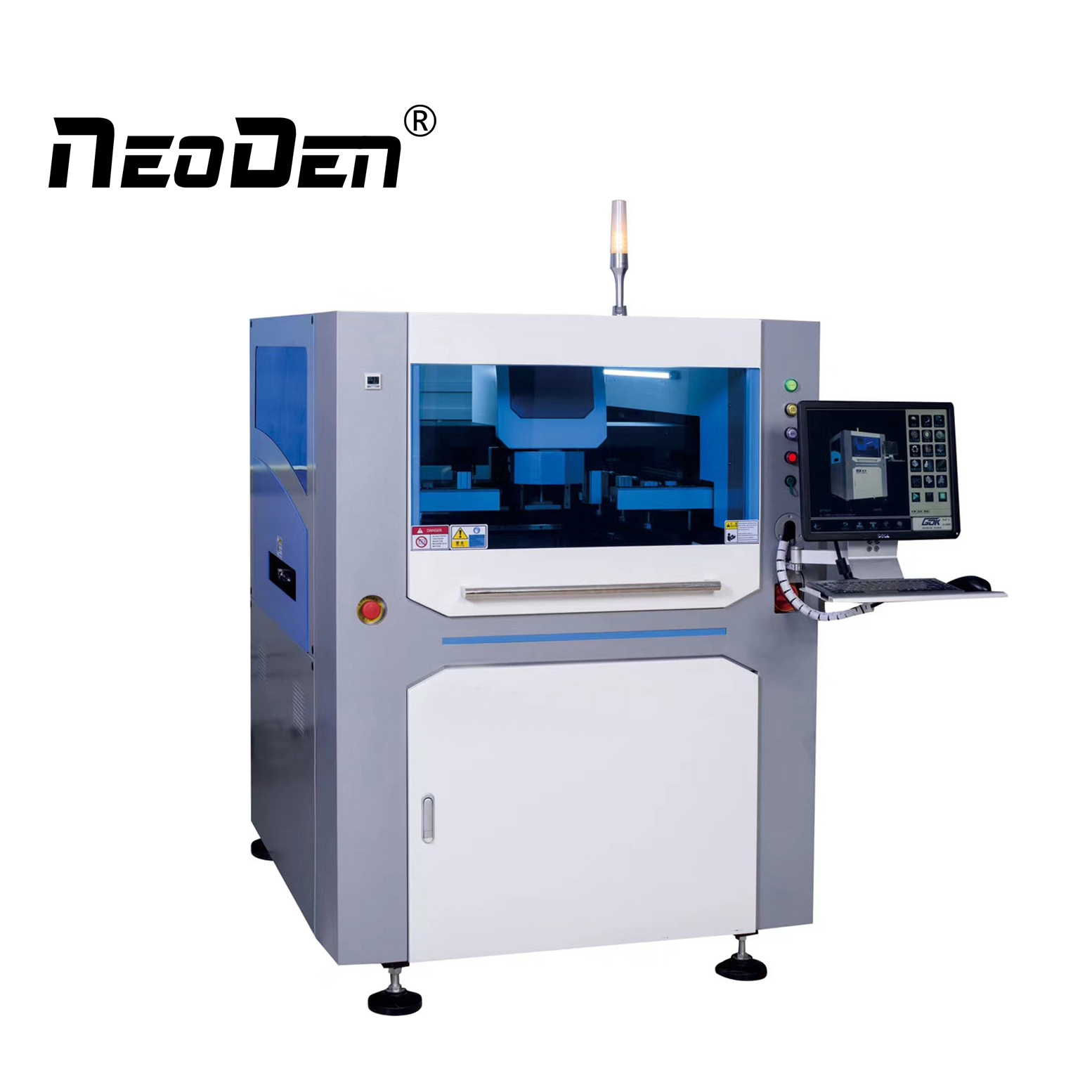

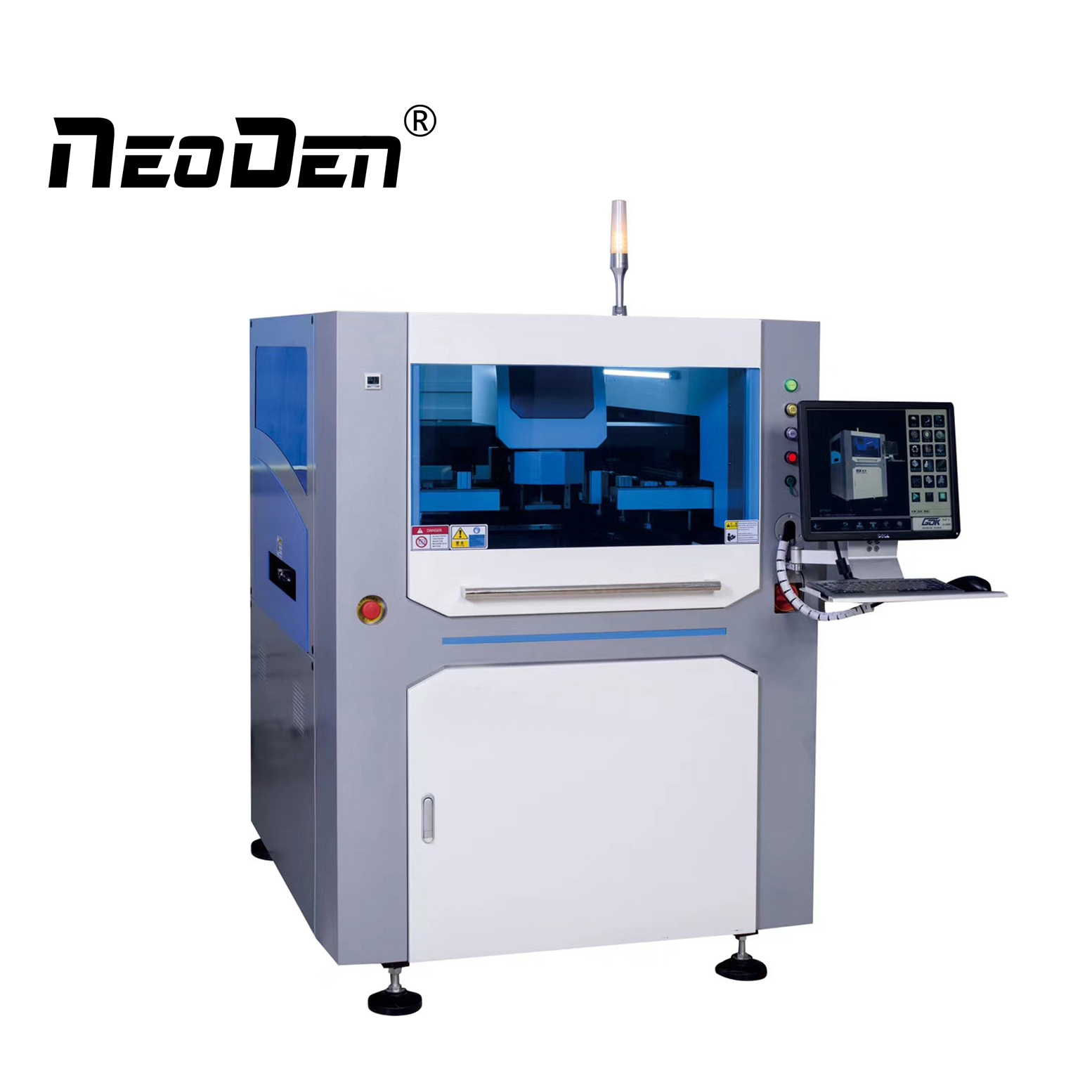

Steps for Solder Paste Printing Machine Working

1. PCB boards are fed into the solder paste printer along the conveyor belt. 2. The machine finds the main edge of the PCB and positions it. 3. The Z-frame moves up to the position of the vacuum board. 4. Add vacuum and fix the PCB firmly in the specific position. 5. Visual axis (lens) slowly mov...Read more -

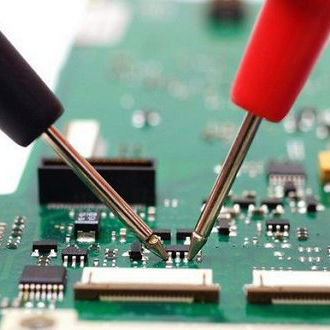

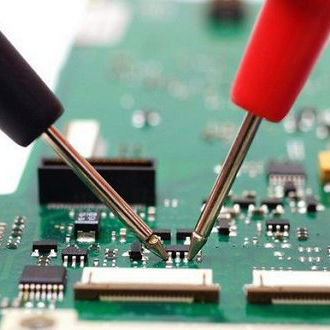

The process of PCBA repair

Generally we patch processing factory in the maintenance technology yuan will carry out the following operations. 1. Check the components In SMT chip processing plant in the product needs to be repaired when the first thing to determine, the components of each solder point there is no error, leak...Read more -

What are the six principles of PCB wiring?

Zhejiang NeoDen Technology Co., LTD., founded in 2010, is a professional manufacturer specialized in SMT mounting machine, reflow oven, stencil printer, SMT production line and other SMT Products. We have our own R & D team and own factory, taking advantage of our own rich experienced R&D...Read more -

What does the accuracy of the SMD processing refer to?

In the process of PCBA processing, the accuracy of SMT mounting machine can be roughly divided into several parameters such as positioning accuracy, repetition accuracy and resolution. Here is a brief introduction to the common precision meaning of pick and place machine china. 1.Positioning acc...Read more -

How is the vision system of SMT machine composed?

In SMD mounting machine vision system we can more accurately determine the current components, circuit boards or SMT suction nozzle position, rely on the visual recognition system we can provide more accurate placement for the placement machine then you understand how this system is composed of? ...Read more -

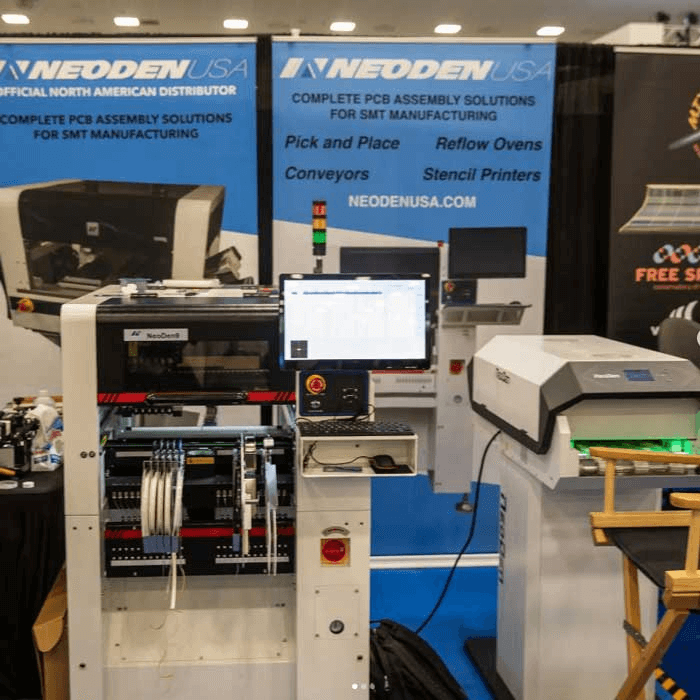

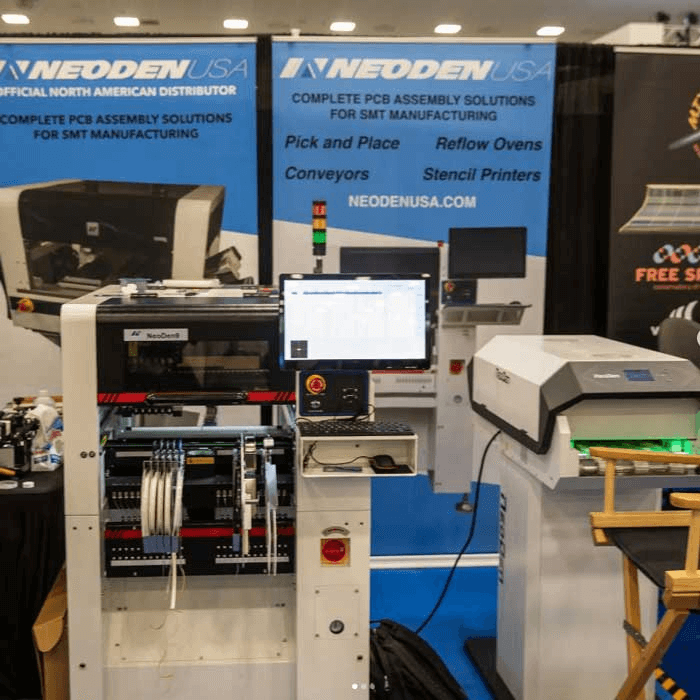

NeoDen in Summer NAMM Show 2022

We’re at Summer NAMM 2022 with the brand new NeoDen9 pick and place machine! Come check out a demo, North Hall, booth 15714. June 3–5 Summer NAMM 2022 in Los Angeles! Our US agent NeoDen USA take part in this exhibition and attracted a lot electronics enthusiasts’ attention. It Left ...Read more