News

-

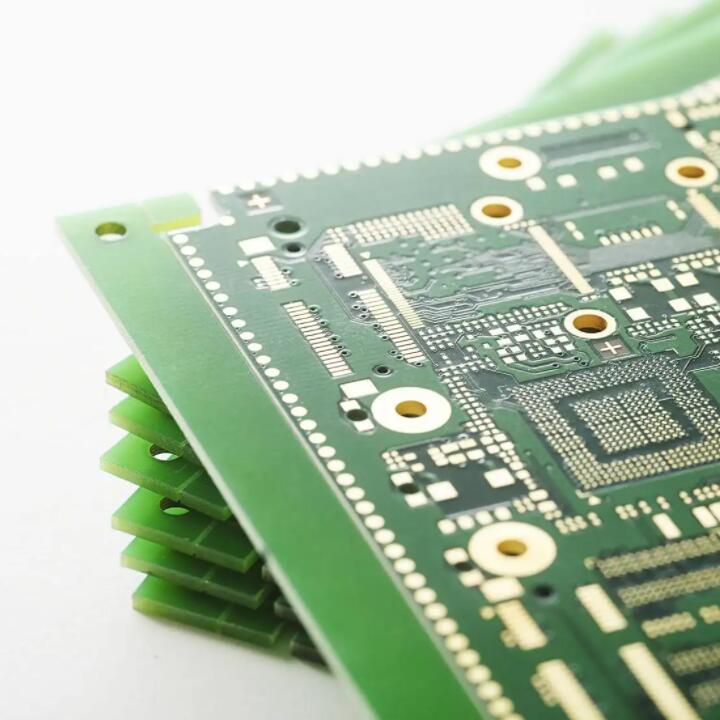

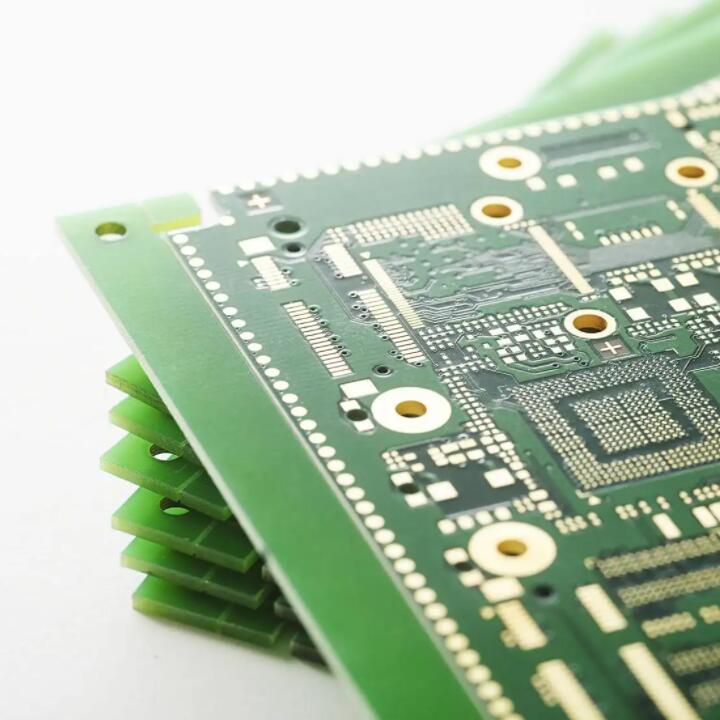

High-speed PCB design layout ideas and principles

Layout ideas In the PCB layout process, the first consideration is the size of the PCB. Next, we should consider the devices and areas with structural positioning requirements, such as whether there is a height limit, width limit and punching, slotted areas. Then according to the circuit signal a...Read more -

What is the difference between wave soldering and manual soldering?

1. Manual welding for the amount of solder and solder wetting angle control, welding consistency of the grasp, metallization hole over the tin rate requirements are almost all more difficult, especially when the electronic components pin is gold-plated, it is necessary to complete the tin-lead so...Read more -

What does reflow oven reflow mean?

Reflow oven reflow is the process of solder paste in reaching the melting point of the paste, in its liquid surface tension and the role of flux flux back to the component pins to form a solder joint, so that the circuit board pads and components soldered into a whole, also called reflow process....Read more -

How to improve the productivity of smt machine?

In the SMT production line involves the machine throwing rate problem. high SMT machine throwing rate seriously affects the production efficiency. If it is within the range of normal values, it is a normal problem, if the throwing rate value of the proportion is relatively high, then there is a p...Read more -

Reflow Oven Chamber Cleaning Method

After a period of use, the reflow oven chamber contains a large amount of rosin flux residue on the inner wall of the reflow chamber and the cooling zone pipes, which will reduce the heat temperature of the reflow soldering and lead to poor soldering quality. Therefore, the reflow oven chamber ne...Read more -

SMT Welding Method and Related Notes

Welding is SMT chip processing process is indispensable link, if in this a link presented mistakes will directly affect the chip processing circuit board failed and even scrapped, so in the welding need to grasp the correct welding method, understand the relevant matters of attention to avoid pro...Read more -

4 Types of SMT Rework Equipment

SMT rework stations can be divided into 4 types according to their construction, application and complexity: simple type, complex type, infrared type and infrared hot air type. 1. Simple type: this kind of rework equipment is more common than independent soldering iron tool function, can choose t...Read more -

How to prevent the placement machine human error material?

SMT machine needs to use a lot of electronic materials, electronic materials are generally loaded with trays or reels. When the production line began mass production, the need for material, when the material is almost finished, it is necessary to receive material, when the batch of PCBA board pro...Read more -

SMT machine mark point identification bad and those factors related?

SMT machine to mount electronic components to PCB designated pads, the preliminary need according to the bom table and Gerber file to write the SMD program instructions, SMD program editing into the computer control system of pick and place machine, and then SMT machine will pick up the correspon...Read more -

What Causes SMT Machine Inductor Failure?

Inductive failure is a fault that we often encounter in the process of automatic mounter placement production, many times due to SMT machine inductive failure reduces the effect and rate of our placement. Then we should how to solve this fault? Usually, cause inductor failure is usually composed ...Read more -

6 Tips for PCB Design to Avoid Electromagnetic Problems

In PCB design, electromagnetic compatibility (EMC) and the associated electromagnetic interference (EMI) have traditionally been two major headaches for engineers, especially in today’s circuit board designs and component packages continue to shrink, OEMs require higher speed systems. In th...Read more -

What Are The PCBA Cleanliness Inspection Methods?

Visual inspection method Using a magnifying glass (X5) or an optical microscope to PCBA, the quality of cleaning is assessed by observing the presence of solid residues of solder, dross and tin beads, unfixed metal particles and other contaminants. It is usually required that the PCBA surface mus...Read more