How to use solder paste in PCBA process?

(1) Simple method for judging the viscosity of solder paste: Stir the solder paste with a spatula for about 2-5 minutes, pick up a little solder paste with the spatula, and let the solder paste fall down naturally. The viscosity is moderate; if the solder paste does not slip off at all, the viscosity of the solder paste is too high; if the solder paste keeps slipping off quickly, the viscosity of the solder paste is too small;

(2) Storage conditions of solder paste: refrigerate in a sealed form at a temperature of 0°C to 10°C, and the storage period is generally 3 to 6 months;

(3) After the solder paste is taken out of the refrigerator, it must be warmed up at room temperature for more than 4 hours before it can be used. The heating method cannot be used to return to temperature; after the solder paste is warmed up, it needs to be stirred (such as mixing with a machine, stirring 1-2 Minutes, stirring by hand needs to be stirred for more than 2 minutes) before use;

(4) The ambient temperature for solder paste printing should be 22℃~28℃, and the humidity should be below 65%;

(5) Solder paste printing 1. When printing solder paste, it is recommended to use solder paste with a metal content of 85% to 92% and a service life of more than 4 hours;

1. When printing solder paste, it is recommended to use solder paste with a metal content of 85% to 92% and a service life of more than 4 hours;

2. Printing speed During printing, the travel speed of the squeegee on the printing template is very important, because the solder paste needs time to roll and flow into the die hole. The effect is better when the solder paste rolls evenly on the stencil.

3. Printing pressure The printing pressure must be coordinated with the hardness of the squeegee. If the pressure is too low, the squeegee will not clean the solder paste on the template. If the pressure is too large or the squeegee is too soft, the squeegee will sink to the template. Dig out the solder paste from the large hole. The empirical formula for pressure: Use a scraper on a metal template. In order to get the correct pressure, start by applying 1 kg of pressure for every 50 mm of the scraper length. For example, a 300 mm scraper applies a pressure of 6 kg to gradually reduce the pressure. Until the solder paste starts to remain on the template and is not scratched cleanly, then gradually increase the pressure until the solder paste is just scratched off. At this time, the pressure is optimal.

4. Process management system and process regulations In order to achieve good printing results, it is necessary to have the correct solder paste material (viscosity, metal content, maximum powder size and lowest possible flux activity), the correct tools (printing machine, template and Combination of scraper) and correct process (good positioning, cleaning and wiping). According to different products, set the corresponding printing process parameters in the printing program, such as working temperature, working pressure, squeegee speed, demoulding speed, automatic template cleaning cycle, etc. At the same time, it is necessary to formulate a strict process management system and process regulations.

① Use the solder paste within the validity period strictly in accordance with the designated brand. The solder paste should be stored in the refrigerator on weekdays. It should be placed at room temperature for more than 4 hours before use, and then the lid can be opened for use. The used solder paste should be sealed and stored separately. Whether the quality is qualified.

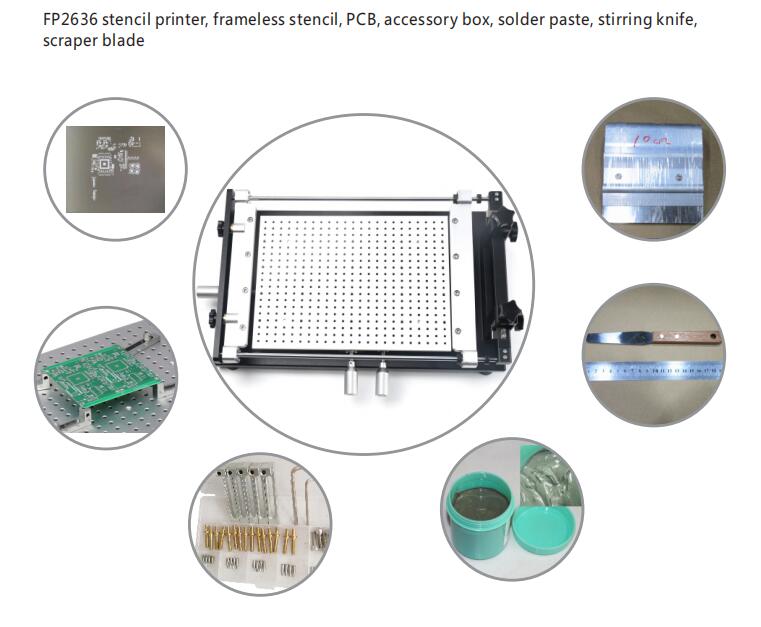

② Before production, the operator uses a special stainless steel stirring knife to stir the solder paste to make it even.

③ After the first printing analysis or equipment adjustment on duty, the solder paste thickness tester shall be used to measure the printing thickness of the solder paste. The test points are selected at 5 points on the test surface of the printed board, including the upper and lower, left and right and middle points, and record the values. The thickness of the solder paste ranges from -10% to +15% of the template thickness.

④ During the production process, 100% inspection is performed on the printing quality of the solder paste. The main content is whether the solder paste pattern is complete, whether the thickness is uniform, and whether there is solder paste tipping.

⑤ Clean the template according to the process requirements after the on-duty work is completed.

⑥ After the printing experiment or printing failure, the solder paste on the printed board should be thoroughly cleaned with ultrasonic cleaning equipment and dried, or cleaned with alcohol and high-pressure gas to prevent the solder paste on the board from being caused when it is used again. Solder balls and other phenomena after reflow soldering

NeoDen provides a full SMT assembly line solutions, including SMT reflow oven, wave soldering machine, pick and place machine, solder paste printer, PCB loader, PCB unloader, chip mounter, SMT AOI machine, SMT SPI machine, SMT X-Ray machine, SMT assembly line equipment, PCB production Equipment SMT spare parts, etc any kind SMT machines you may need, please contact us for more information:

Hangzhou NeoDen Technology Co., Ltd

Post time: Jul-21-2020