At present, many advanced electronic product manufacturers at home and abroad have proposed a new equipment maintenance concept “synchronous maintenance” in order to further reduce the impact of maintenance on production efficiency. That is, when the reflow oven is working at full capacity, the automatic maintenance switching system of the equipment is used to make the maintenance and maintenance of the reflow oven completely synchronized with production. This design completely abandons the original “shutdown maintenance” concept, and further improves the production efficiency of the entire SMT line.

Requirements for process implementation:

High-quality equipment can only produce benefits through professional use. At present, many problems encountered by the majority of manufacturers in the production process of lead-free soldering have not only come from the equipment itself, but need to be resolved through adjustments in the process.

l Setting of furnace temperature curve

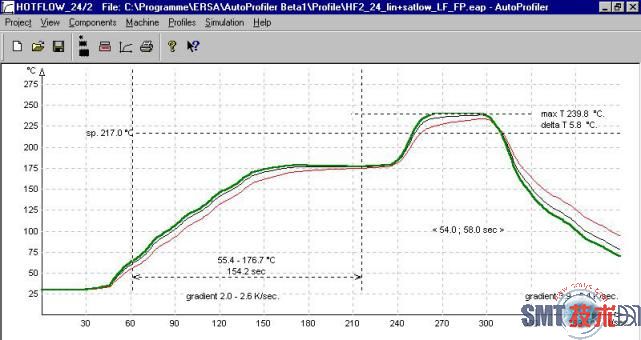

Because the lead-free soldering process window is very small, and we must ensure that all solder joints are within the process window at the same time in the reflow area, therefore, the lead-free reflow curve often sets a “flat top” (see Figure 9).

Figure 9 “Flat top” in the furnace temperature curve setting

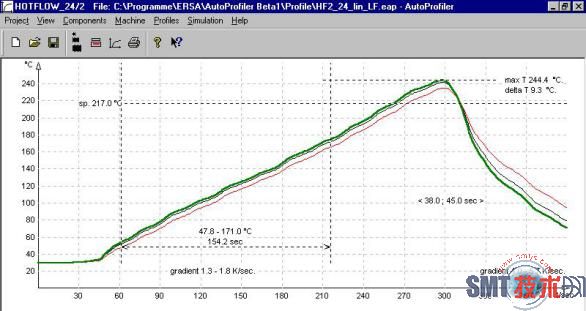

If the original components on the circuit board have little difference in thermal capacity but are more sensitive to thermal shock, it is more suitable to use a “linear” furnace temperature curve. (See Figure 10)

Figure 10 “Linear” furnace temperature curve

The setting and adjustment of the furnace temperature curve depends on many factors such as equipment, original components, solder paste, etc. The setting method is not the same, and experience must be accumulated through experiments.

l Furnace temperature curve simulation software

So are there some methods that can help us quickly and accurately set the furnace temperature curve? We can consider generating software with the help of furnace temperature curve simulation.

Under normal circumstances, as long as we tell the software the condition of the circuit board, the condition of the original device, the board interval, the chain speed, the temperature setting and the equipment selection, the software will simulate the furnace temperature curve generated under such conditions. This will be adjusted offline until a satisfactory furnace temperature curve is obtained. This can greatly save the time for process engineers to repeatedly adjust the curve, which is especially important for manufacturers with many varieties and small batches.

The future of reflow soldering technology

Mobile phone products and military products have different requirements for reflow soldering, and circuit board production and semiconductor production have different requirements for reflow soldering. Small-variety and large-volume production began to slowly decrease, and the differences in equipment requirements for different products began to appear day by day. The difference between reflow soldering in the future will not only be reflected in the number of temperature zones and the choice of nitrogen, the reflow soldering market will continue to be subdivided, which is the foreseeable development direction of reflow soldering technology in the future.

Post time: Aug-14-2020