With the wide application of 0201 chip components and 0.3 Pinch integrated circuit, enterprises have higher and higher requirements for product quality, which cannot be guaranteed by visual inspection alone. At this time, AOI technology arises at the right moment. As a new member of SMT production line, AOI effectively solves the problem of difficult surface patch quality detection.

AOI has a lot in common with the presses and mounters mentioned before, except that it is not a production facility like the solder printer and SMT machine. Although it is not production equipment, it has an inseparable relationship with production. This task enables you to grasp the working principle of AOI through a comprehensive introduction.

1.The classification of the AOI

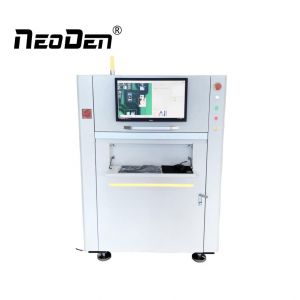

The full name of AOI is Automatic Optic Inspection, which is an equipment that detects common defects encountered in welding production based on optical principle. AOI is a new testing technology in recent years, but it has developed rapidly. At present, many factories have introduced AOI testing equipment. AOI is the position in the production line is different, can be divided into online type and offline type AOI. There is a division of labor, but they all work on the same principle.

2.Online AOI:

it is an optical detector that can be put on the assembly line and used with other equipment on the SMT assembly line at the same time. The rhythm is the same as that of other equipment in the production line, and can be placed in different positions on the production line according to different purposes of testing. Online AOI adopts 100% to achieve full inspection, with a high degree of automation, and all the inspections are automatically completed along with the pipeline. ESD worry is low, because it is an automatic operation, detection links do not have to consider this problem. The manual labor intensity of online AOI is also very low, and basically does not need manual assistance except for equipment programming. And there’s no pollution.

3.Offline AOI:

It is an optical detector that can not be put on the assembly line together with the SMT assembly line, but it can be put on other places to detect the PCB board on the SMT assembly line. Off-line testing is sampling or batch sampling, which is moderately automated and requires manual assistance to complete the inspection. ESD concerns are high because the inspection process requires worker assistance and sensitive components need to be handled with extra care. In the process of using offline AOI, the inspection of each board shall be manually put in and taken out after the inspection. Compared with online AOI, offline AOI will cause light pollution, and the inspector will be long-term stimulated by high brightness light source in close contact.

4.The structure of the AOI

Both online AOI and offline AOI have the same structure and principle, which is usually composed of image acquisition, motion control system, image processing system and data processing system. Compared with other SMT devices, AOI structure is relatively simple.

Post time: Jan-06-2021