Reflow Solder Machine – NeoDen desktop SMT reflow oven soldering machine – Neoden

Reflow Solder Machine – NeoDen desktop SMT reflow oven soldering machine – Neoden Detail:

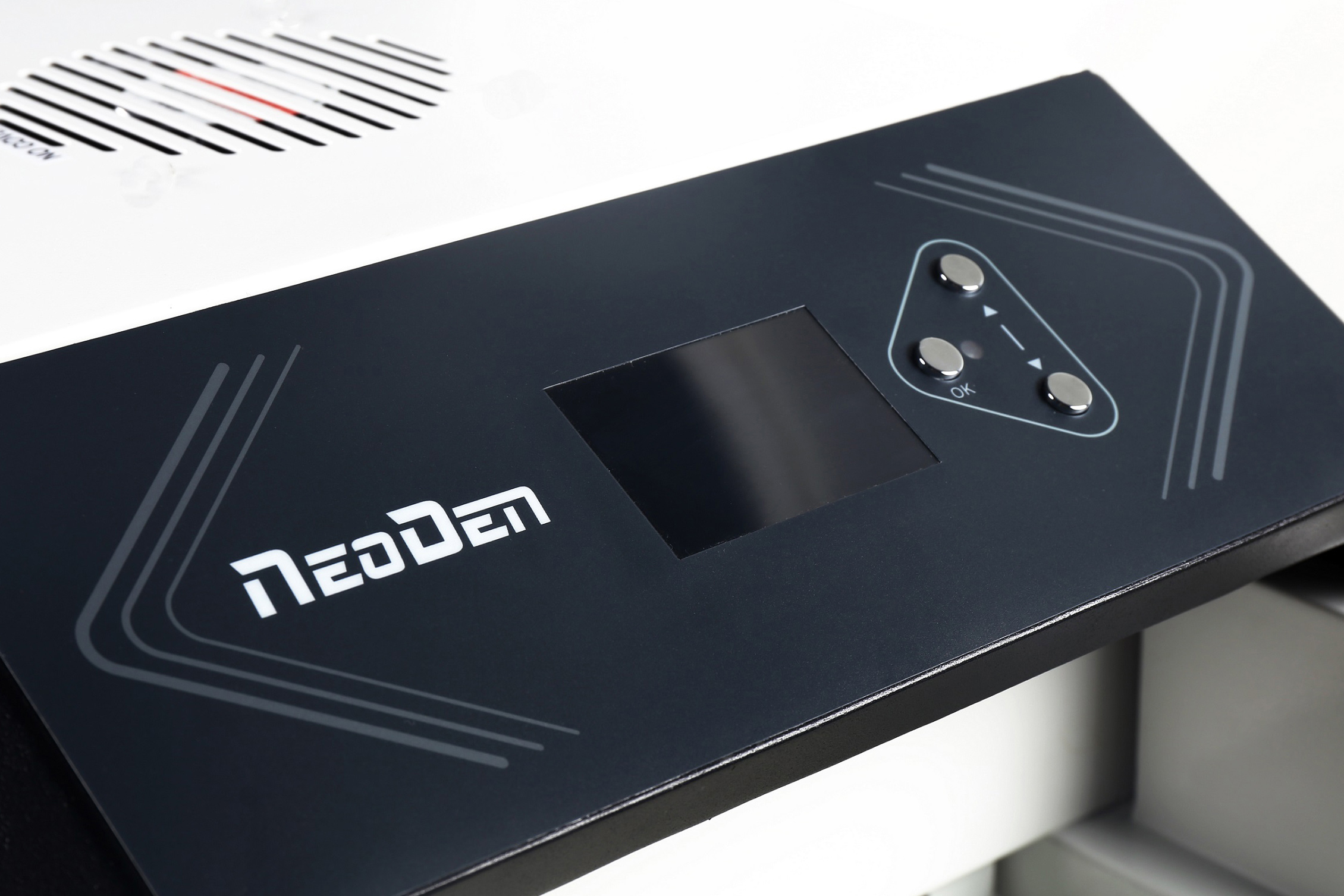

NeoDen desktop SMT reflow oven soldering machine

Brief Introduction

IN6 is a newly designed, environmentally friendly reflow oven with stable performance. It can achieve full hot-air convection, excellent soldering performance. It has 6 temperature zone, light and compact. Intelligent temperature control with high sensitivity temperature sensor, temperature can be stable within ±0.2°C. It adopts Japan NSK hot air motor bearing and Swiss imported heating wire, which is durable and stable. CE approved, provide authoritative quality assurance.

Specification

| Product Name | NeoDen desktop SMT reflow oven soldering machine |

| Power requirement | 110/220VAC 1-phase |

| Power max. | 2KW |

| Heating zone quantity | Upper3/ down3 |

| Conveyor speed | 5 – 30 cm/min (2 – 12 inch/min) |

| Standard Max Height | 30mm |

| Temperature control range | Room temperature~300 degree celsius |

| Temperature control accuracy | ±0.2 degree celsius |

| Temperature distribution deviation | ±1 degree celsius |

| Soldering width | 260 mm (10 inch) |

| Length process chamber | 680 mm (26.8 inch) |

| Heat-up time | approx. 25 min |

| Dimensions | 1020*507*350mm(L*W*H) |

| Packing Size | 112*62*56cm |

| N.W./ G.W. | 49KG/64kg (without working table) |

Detail

Heating zones

6 zones design, (3 top, 3 bottom)

Full hot-air convection

Intelligent control system

Several working files can be stored

Color touch screen

Saving energy and Eco-friendly

Built-in solder smoke filtering system

Reinforced heavy-duty carton package

Our Service

1. More Professional service in Packaging and printing products exporting field

2. Better manufacture ability

3. Various payment term to choose: T/T, Western Union, L/C, Paypal

4. High quality/Safe material/Competitive price

5. Small order available

6. Quickly response

7. More safe and fast transport

Provide one-stop SMT assembly production line

Related products

|

|

|

|

| Stencil printer FP2636 | SMT machine NeoDen4 | Automatic conveyor J12 | Pick and place machine K1830 |

FAQ

Q1: When can I get the quotation?

A: We usually quote within 8 hours after we get your inquiry.

If you are very urgent to get the price, please tell us so that we will regard your inquiry priority.

Q2: What about the lead time for mass production?

A: 15-30 working days for mass production.It depends on your quantity,and we will try our best to meet your needs.

Q3: What is your terms of delivery?

A: EXW, FOB, CIF, etc.

About us

If you need, please feel free to contact us for more information.

Product detail pictures:

Related Product Guide:

Defect analysis of reflow welding

With our leading technology at the same time as our spirit of innovation,mutual cooperation, benefits and development, we are going to build a prosperous future alongside one another with your esteemed enterprise for Reflow Solder Machine – NeoDen desktop SMT reflow oven soldering machine – Neoden , The product will supply to all over the world, such as: United States, Macedonia, Sierra Leone, Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers' expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, be sure to feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our merchandise, make sure you feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.