China Table Top Pick And Place Machine – Neoden 4 SMT pick and place machine with vision system – Neoden

China Table Top Pick And Place Machine – Neoden 4 SMT pick and place machine with vision system – Neoden Detail:

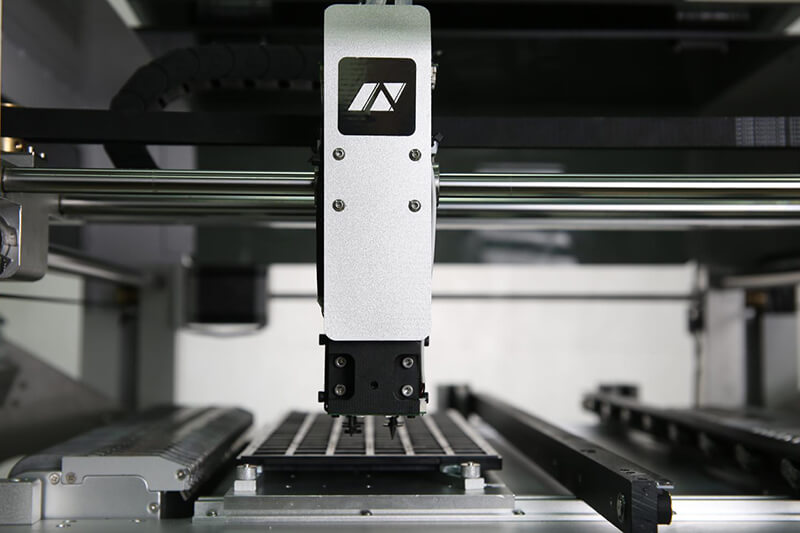

NeoDen4 is a pick and place machine of components flexibility, PCB flexibility and production flexibility.

NeoDen4 is a pick and place machine of components flexibility, PCB flexibility and production flexibility. It is equipped with dual CCD cameras, auto rails, auto electronic feeders and 4 placement heads, which could support to mount 0201, BGA, QFN.

NeoDen4 is the best choice to satisfy all demands of high precision, high capacity, stable performance and low cost. This is a huge breakthrough not only for NeoDen, but also for small and medium-sized enterprises, those who want to improve placement

accuracy and speed up PCB assembly with a limited budget.

Spotlights

1.Vision system

An up-looking camera and a down-looking camera identifies and calibrates the different components simultaneously, and tremendously improves the accuracy of placement from 0201 to BGA

2. Four precision heads

4 high-precision placement heads with ±180° rotation that adopts suspended, fully symmetric and high degree

of coupling way, to ensure it can mount components with higher space, more gentle and more accurate

3. Auto Electronic Feeders

Adopts feeding error corrections technique to help smooth the picking and reduce the deviation

4. General conveyor is supported

With a conveyor port, One-Stop SMT production line can be setup, which is more time-saving and labor-saving

5. Supports remote system upgrade

NeoDen will provide a life-long technical service and system upgrade

6. Industrial PC motherboard

32G solid state drives, read/write faster and more stable, with power-off protection function

Exhibition

Specifications

| Model | NeoDen4 without rails | ||

| Machine style | Single gantry with 4 heads | ||

| Alignment | Stage Vision | ||

| Placement Rate | Vision on | 5,000CPH | |

| Vision off | 10,000CPH(Optimum) | ||

| Feeder Capacity | Tape feeder:48(all 8mm) | ||

| Vibration feeder:5 | |||

| Tray feeder:5 | |||

| Component Range | Smallest Size | 0201 | |

| Largest Size | 32x32mm (Lead Pitch 0.5mm) | ||

| Max Height | 5mm | ||

| Rotation | ±180° | ||

| Placement Accuracy | ±0.02mm | ||

| X-Y Repeatability | ±0.02mm | ||

| Board Dimension(mm) | Maximum | 350 x 400mm | |

| 140 x400mm(With 1 waffle Tray) | |||

| Main Control | GUI | ||

| Electricity Supply | 110V/220V | ||

| Power | 180W | ||

| External Dimensions(mm) | Machine size | 870(L)x680(W)x480(H) | |

| Packing size | 940(L)x740(W)x600(H) | ||

| Weight | Net Weight | 60kgs | |

| Gross weight | 80kgs | ||

Certificate

Factory

Product detail pictures:

Related Product Guide:

Defect analysis of reflow welding

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of China Table Top Pick And Place Machine – Neoden 4 SMT pick and place machine with vision system – Neoden , The product will supply to all over the world, such as: moldova, kazan, India, They're durable modeling and promoting effectively all over the world. Under no circumstances disappearing major functions in a quick time, it's a really should in your case of excellent good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the company make a terrific efforts to expand its international trade, raise its company profit and raise its export scale. We're confident that we've been planning to possess a vibrant prospect and to be distributed all over the world within the years to come.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.