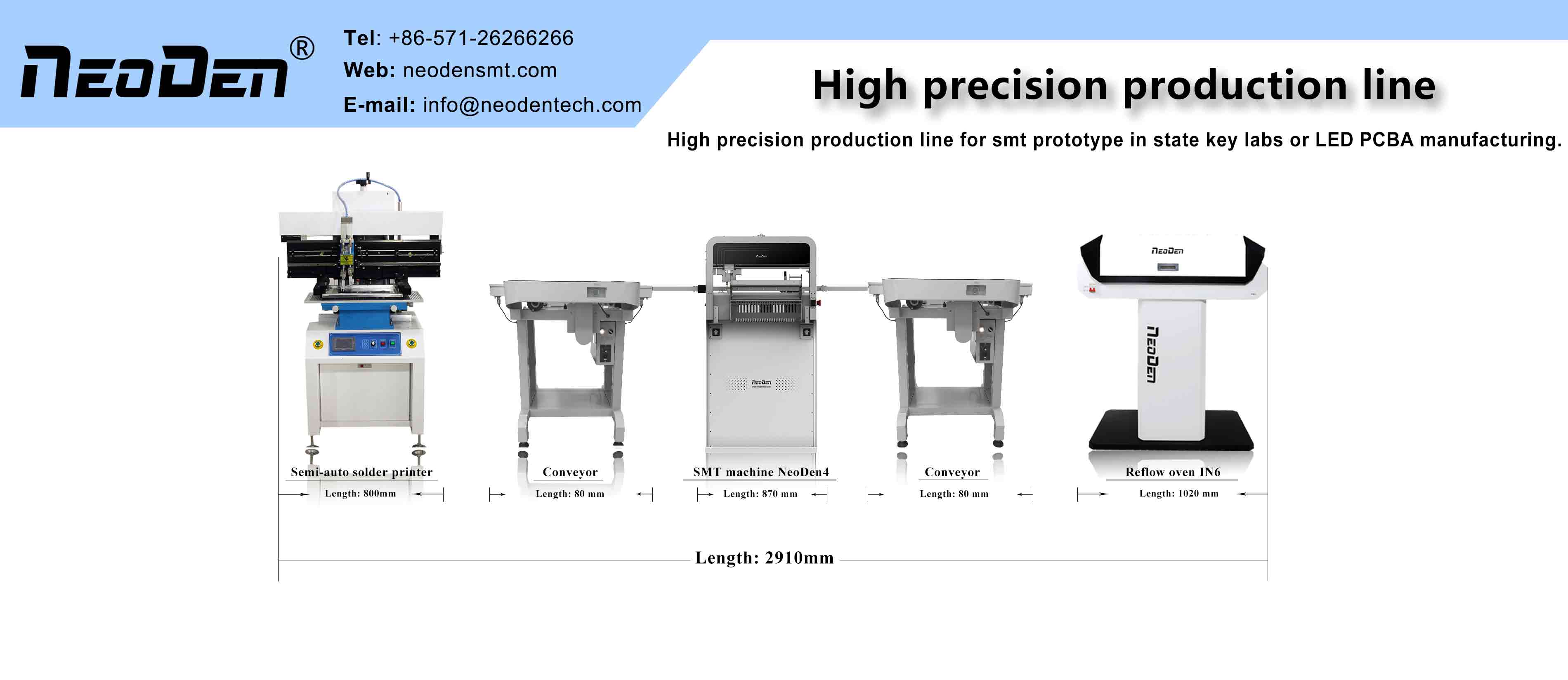

NeoDen4 PCB component mounting machine

NeoDen4 PCB component mounting machine Video

NeoDen4 PCB component mounting machine

Description

At the core, the NeoDen4 is a 4-axis Windows-controlled CNC with four separate vacuum nozzles, each connected to its own vacuum pump.

The machine employs a single X-Y coordinate system covering the entire movement range of the head, which is 310x500mm.

With resolution of .01mm (10µm) and repeatability of .02mm (20µm), any X -Y coordinate can be identified as the location of a feeder, the start of an array of components in a tray or short tape, a fiducial or the location at which a component is to be placed on a circuit board.

Specification

Product name: NeoDen4 PCB component mounting machine

Model: NeoDen4

Machine Style: Single gantry with 4 heads

Placement Rate: 4000 CPH

External Dimension: L 870×W 680×H 480mm

Max applicable PCB: 290mm*1200mm

Feeders: 48pcs

Average working power: 220V/160W

Component Range: Smallest Size: 0201, Biggest Size: TQFP240, Max Height: 5mm

Details

On-line dual rails

Deliver the finished board.

Accommodate different size boards.

Continuous automatic feeding the boards.

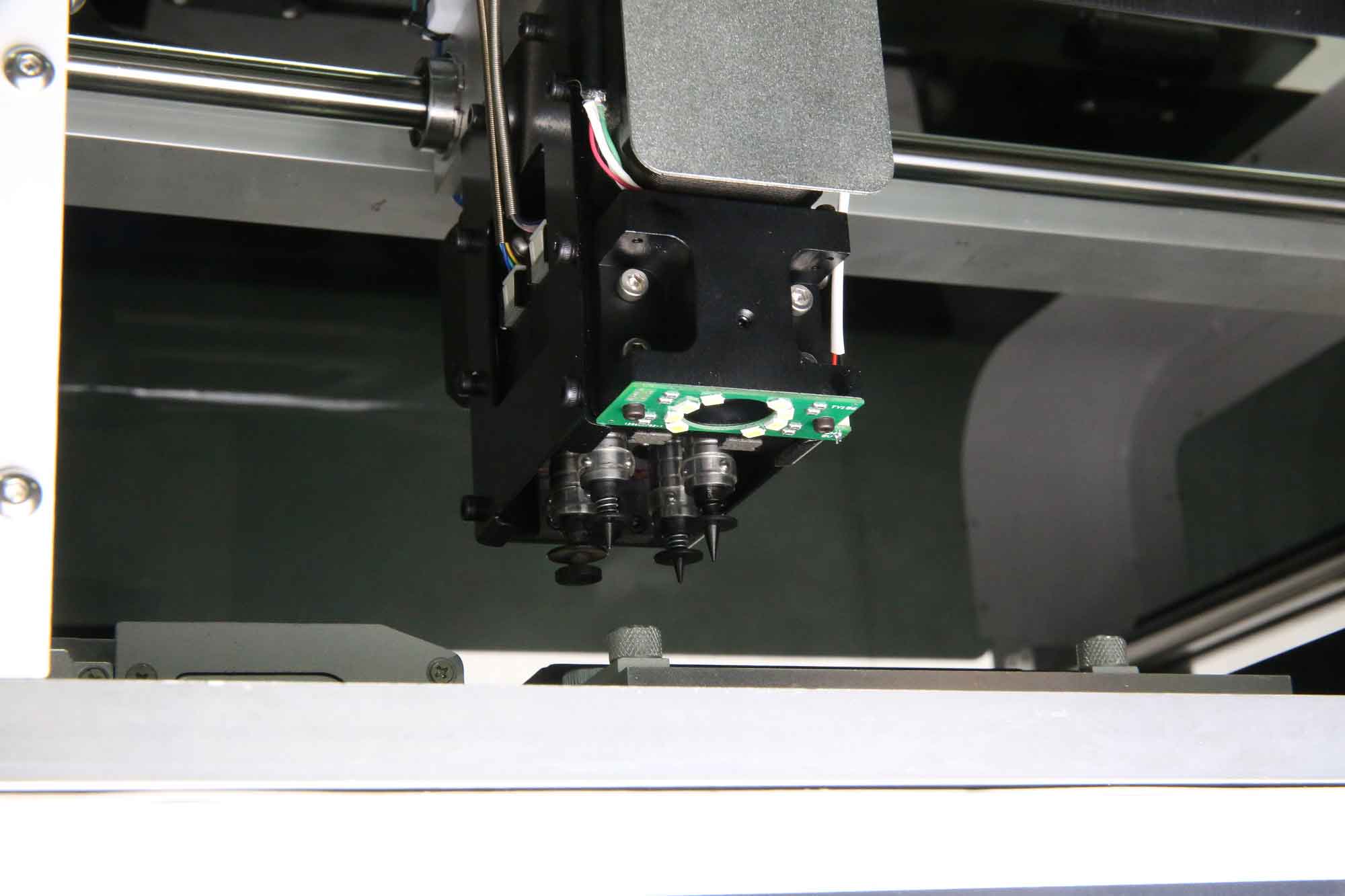

Vision system

Precisely aligned to the nozzles.

Corrects for small errors in component.

High-precision, two-camera vision system.

High precision nozzles

Four high precision mounting heads.

Any size nozzle can be installed.

360 degrees rotation at -180 to 180.

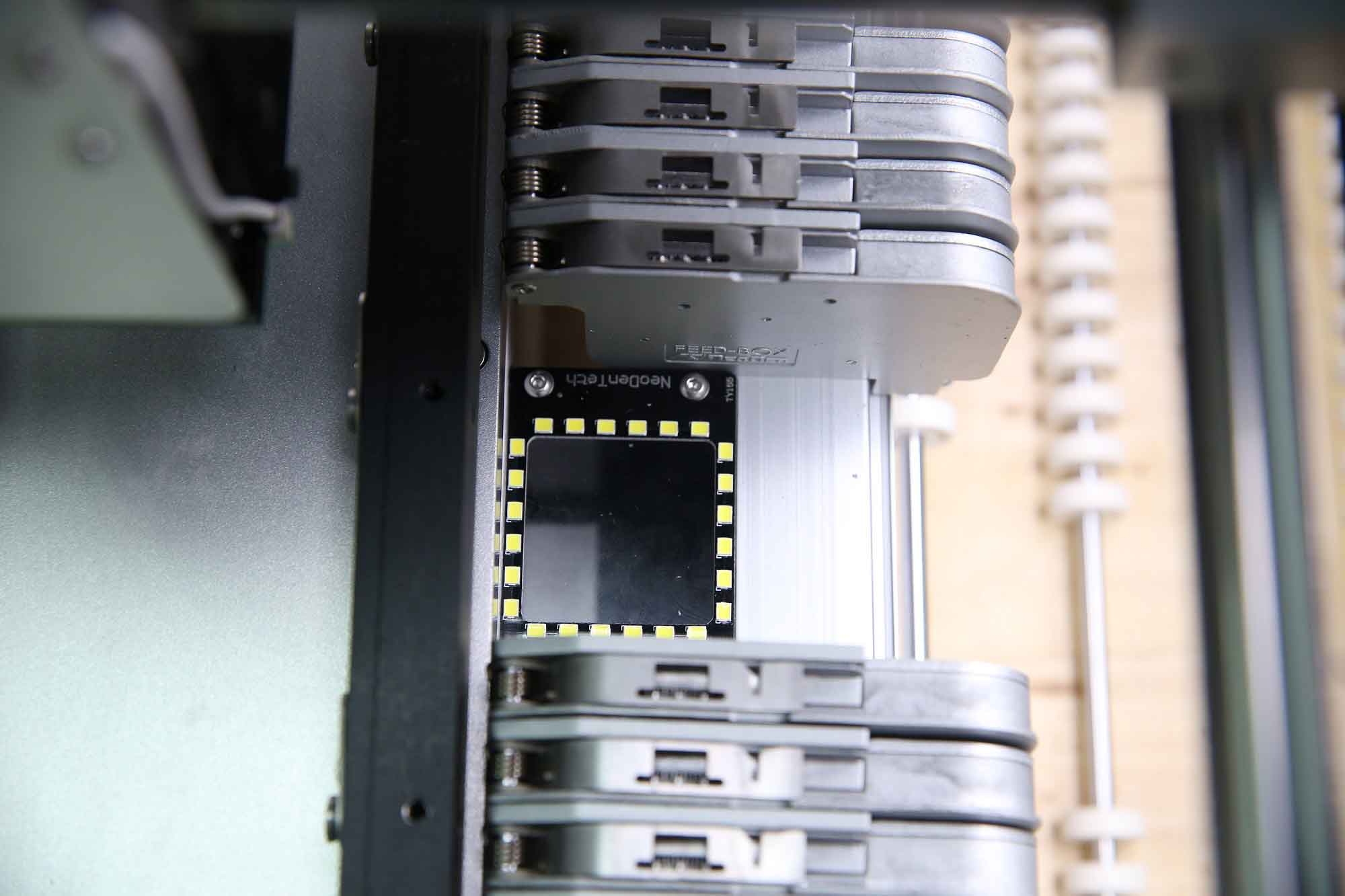

Electric tape-and-reel feeders

Electric tape-and-reel feeders

Accommodate up to 48 8mm tape-and-reel feeders

Any size feeder (8, 12, 16 and 24mm) can be installed in the machine

Package

Edit on the Interface

The entire operation of the NeoDen4 is controlled by a single application that runs automatically after the operating system boots.

Despite the enormous flexibility of the machine, only 7 basic screens are needed to set up feeders, calibrate the vision system and program pick-and-place operations.

This section contains a brief description of the various commands and parameters in the screens. Section contains a recommended workflow to set up, program and operate the machine.

FAQ

Q1: How many workers in your factory?

A: More than 200 workers.

Q2: What is the delivery time for mass production?

A: About 15-30 days.

Q3: Can I request to change the form of packaging and transportation?

A: Yes, We can change the form of the packaging and transportation according to your request, but you have to bear their own costs incurred during this period and the spreads.

About us

Factory

Zhejiang NeoDen Technology Co., Ltd. has been manufacturing and exporting various small pick and place machines since 2010. Taking advantage of our own rich experienced R&D, well trained production, NeoDen wins great reputation from the world wide customers.

We believe that great people and partners make NeoDen a great company and that our commitment to Innovation, Diversity and Sustainability ensures that SMT automation is accessible to every hobbyist everywhere.

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.