NeoDen10 SMT PCB Assembly Machine

NeoDen10 SMT PCB Assembly Machine video

NeoDen10 SMT PCB Assembly Machine

Description

Product name NeoDen10 SMT PCB Assembly Machine

Model: NeoDen 10

IC Tray Capacity: 20

Smallest Component size: 0201 (electronic feeder)

Applicable Components: 0201, Fine-pitch IC, Led Component, Diode, Triode

Component Height Maximum: 16mm

Applicable PCB size: 500mm*300mm (1500 optinal)

Power Supply: 220V, 50Hz (convertible to 110V)

Air source: 0.6MPa

N.W.: 1100Kgs

Product Detail

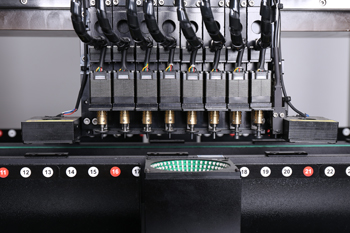

8 heads with Vision enabled

Rotation: +/-180 (360)

High speed repeatable placement accuracy

66 Reel tape feeders

Be calibrated automatically and promptly

Ensure easy operation and high efficiency

Double mark cameras

Better calibration

Improves the overall speed of the machine

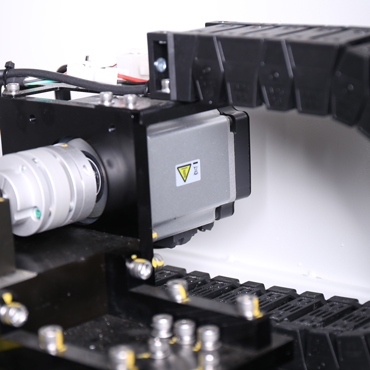

Drive Motor

Panasonic Servo Motor A6

Make the machine to function more accurate

High-definition display

Display size: 12 inch

Makes the machine more convenient to use

Warning light

Triple color of light

Beautiful and elegant indicator design

Description

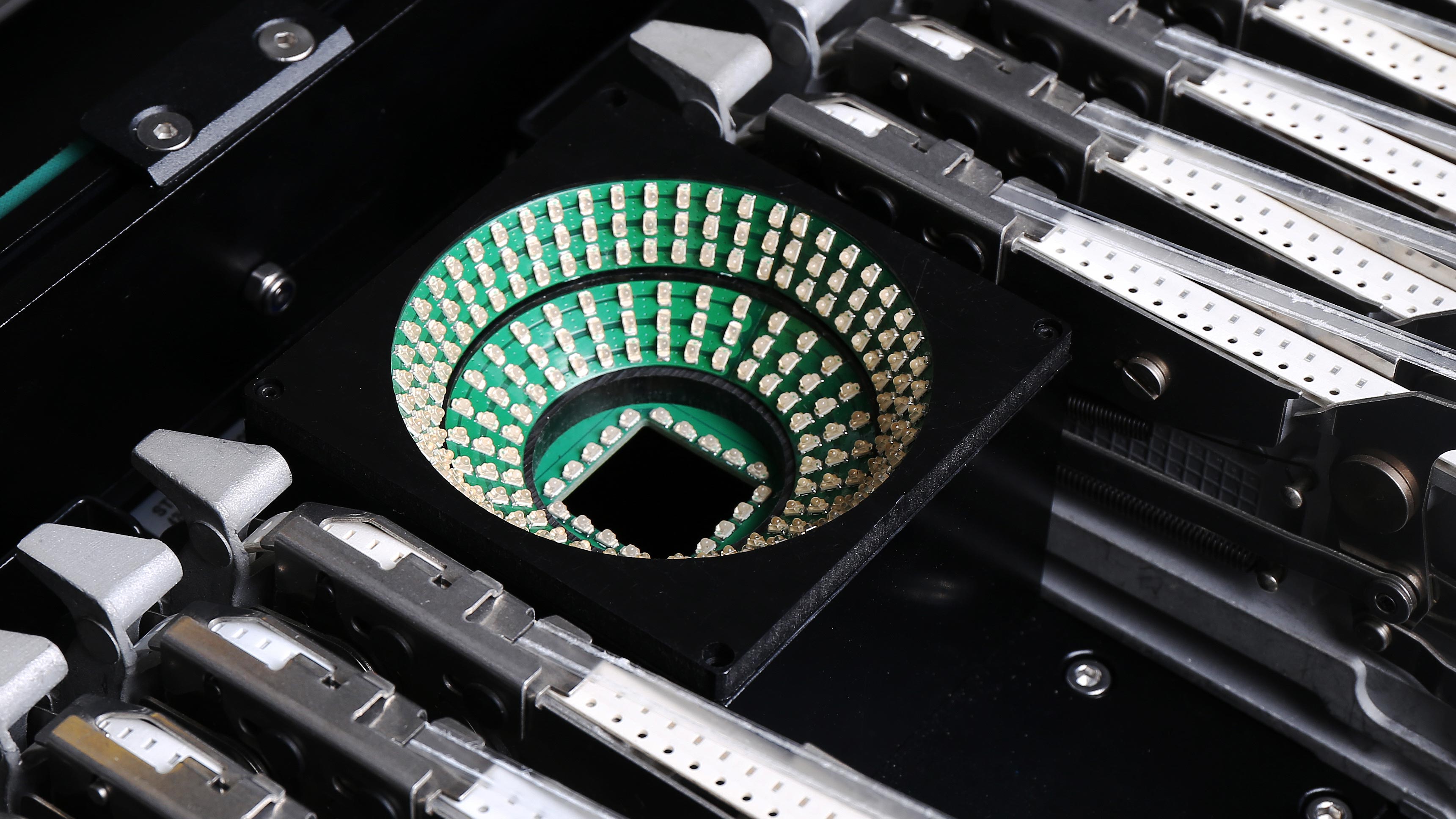

1. Equips double mark camera + double side high precision flying camera ensure high speed and accuracy, real speed up to 13,000 CPH.

Using the real-time calculation algorithm without virtual parameters for speed counting.

2. Front and rear with 2 fourth generation high speed flying camera recognition systems, US ON sensors, 28mm industrial lens, for flying shots and high accuracy recognition.

3. 8 independent heads with fully closed-loop control system support all 8mm feeder pick up simultaneously, speed up to 13,000 CPH.

4. Brand functional parts

Japan: THK-C5 grade grinding screw, Panasonic A6 servo motor, Miki high performance coupling;

Korea: Sungil base, WON linear guide, Airtac valve and other industrial brand parts

All with precision assembly, less wear and aging, stable and durable precision.

Our Service

Provide product instructions

YouTube video tutorials

Experienced after-sales technicians, 24 hours online service

With our own manufactory and more than 10 years of experience in SMT industry

We can provide customers with the most cost-effective products.

Comparison of similar products

If you need, please feel free to contact us for more information.

FAQ

Q1: Which payment form you can accept?

A: T/T, Western Union, PayPal etc.

We accept any convenient and swift payment term.

Q2: What about the lead time for mass production?

A: Honestly, it depends on the order quantity and the season you place the order.

Alway 15-30 days based on general order.

Q3: Is there the products tested before shipping?

A: Yes, of course.

All of our conveyor belt we all will has been 100% QC before shipping.

We test every batch every day.

About us

Factory

Certification

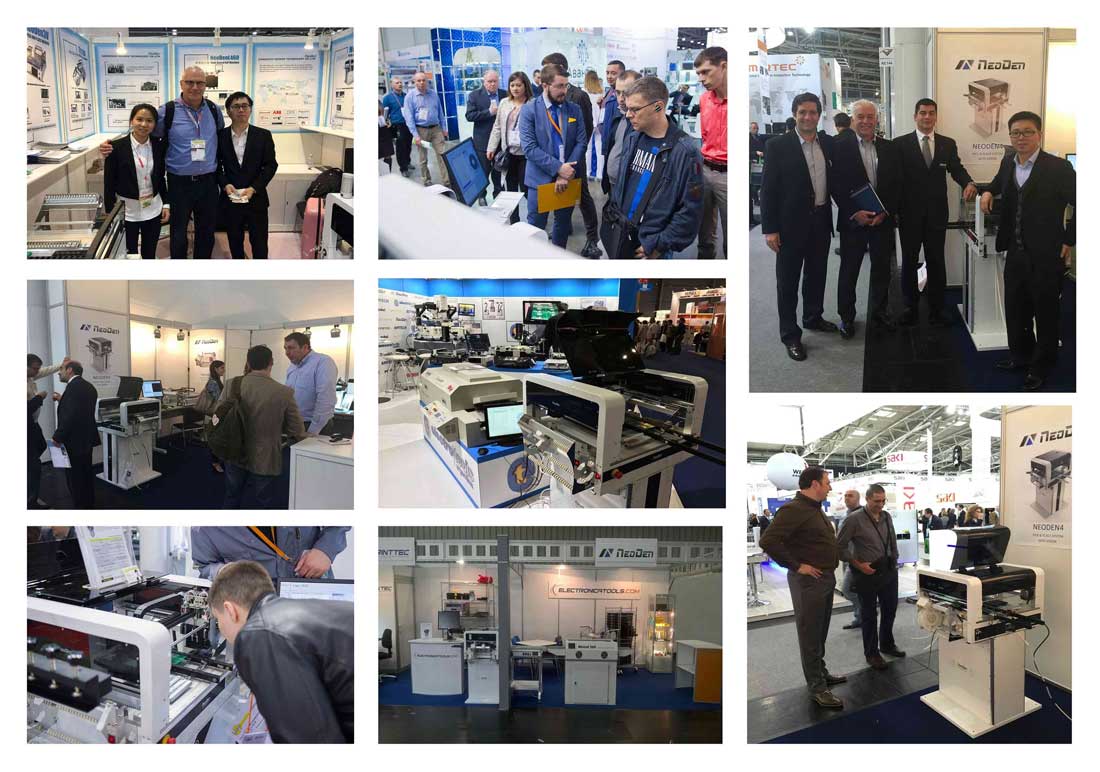

Exhibition

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.