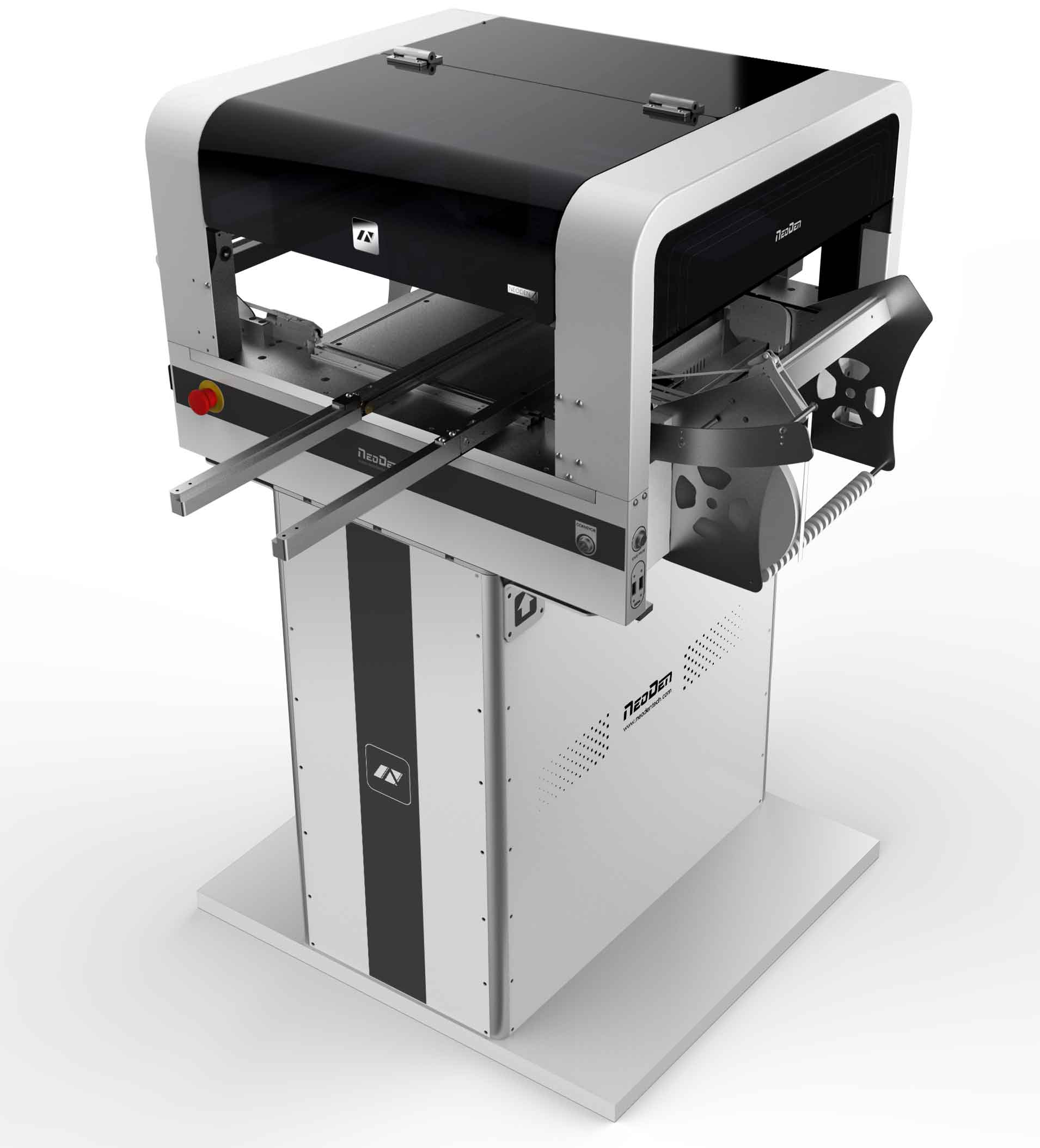

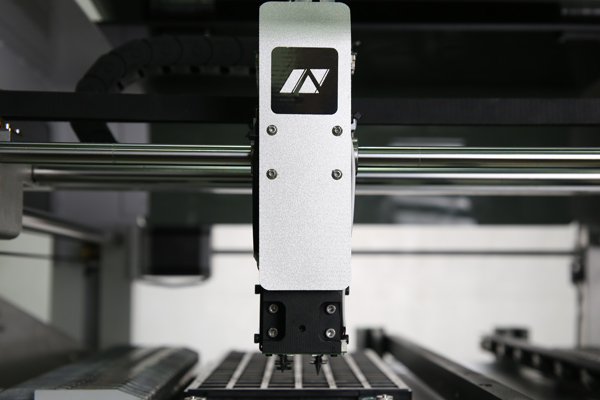

NeoDen Table Top Pick and Place Machine

NeoDen Table Top Pick and Place Machine

The fourth-generation model

Description

Design principles

The NeoDen4 table top pick and place machine is not a knock-off.

It is an original design that has been engineered from the ground-up to provide simple, precise and flexible pick-and-place functionality.

It is ideal for prototyping and small runs, but is equally up to the task of producing large quantities of boards: the PCBs in all NeoDen machines are made using a single NeoDen4.

At NeoDen own factory, NeoDen mills own precision metal parts, winds own motors for the feeders and peelers, writes own proprietary software and assembles machines covered by over 50 patents.

With ISO 9001 certification in pick-and-place quality control, NeoDen rigorously tests each machine for days before shipping.

Specification

Product name: NeoDen Table Top Pick and Place Machine

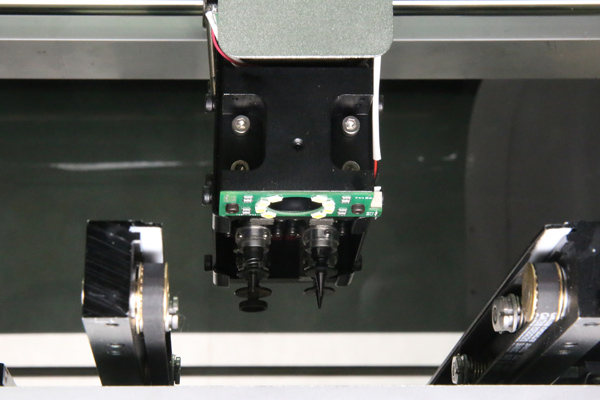

Machine Style: Single gantry with 4 heads

Placement Rate: 4000 CPH

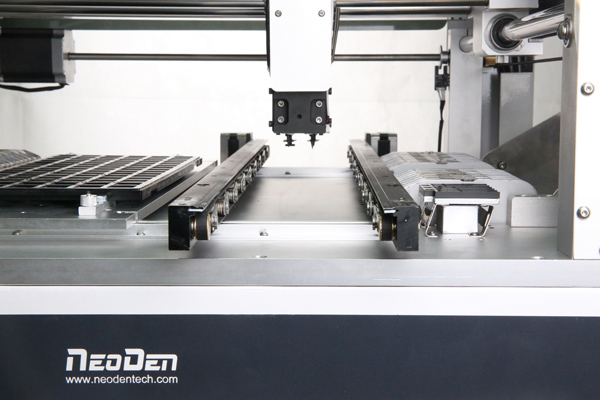

External Dimension: L 870×W 680×H 480mm

Max applicable PCB: 290mm*1200mm

Feeders: 48pcs

Average working power: 220V/160W

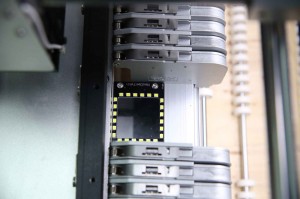

Component Range: Smallest Size: 0201, Biggest Size: TQFP240, Max Height: 5mm

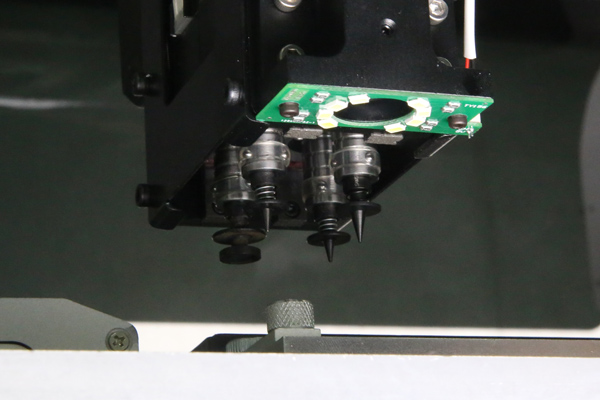

Four placement heads

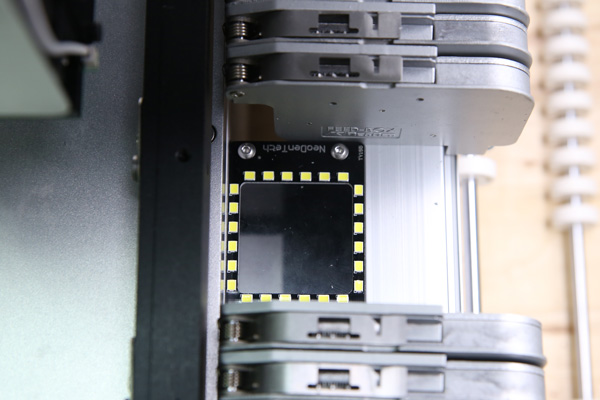

Dual Vision System

Auto Rail

Automatic Electric Feeders

Package

If you need, please feel free to contact us for more information.

About us

Factory

Zhejiang NeoDen Technology Co., Ltd. has been manufacturing and exporting various small pick and place machines since 2010. Taking advantage of our own rich experienced R&D, well trained production, NeoDen wins great reputation from the world wide customers.

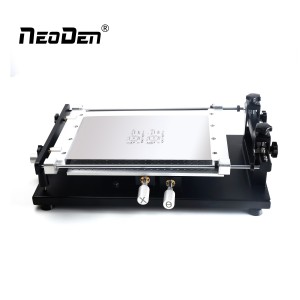

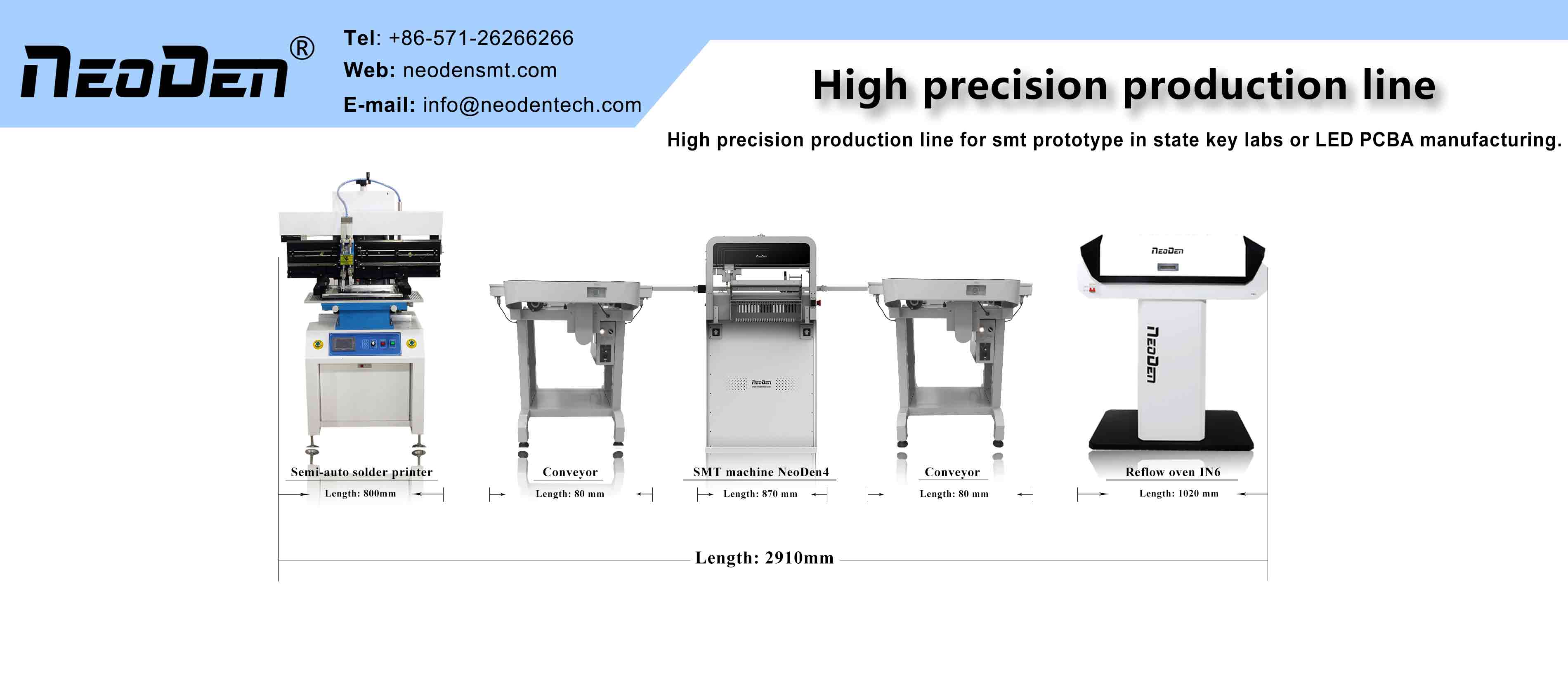

① NeoDen products: Smart series PNP machine, NeoDen K1830, NeoDen4, NeoDen3V, NeoDen7, NeoDen6, TM220A, TM240A, TM245P, reflow oven IN6, IN12, Solder paste printer FP2636, PM3040

② 30+ quality control and technical support engineers, 15+ senior international sales, timely customer responding within 8 hours, professional solutions providing within 24 hours

Certification

Exhibition

FAQ

Q1: How far is your factory from the airport and train station?

A: From airport about 2 hours by car, and from train station about 30 minutes.

We can pick up you.

Q2: Is there the products tested before shipping?

A: Yes, of course. All of our conveyor belt we all will has been 100% QC before shipping. We test every batch every day.

Q3: Can I request to change the form of packaging and transportation?

A: Yes, We can change the form of the packaging and transportation according to your request, but you have to bear their own costs incurred during this period and the spreads.

One Stop SMT Equipments Manufacturer

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.