NeoDen SMT Stencil Machine

NeoDen SMT Stencil Machine

Feature

The operation of the printer is simple.

First, clamp a framed stencil (available at very low cost from most PCB manufacturing houses) into the printer.

Then, place the PCB on the included locator fixtures. Using the Vernier controls, move the PCB fixture until the solder pads perfectly align with the holes.

Finally, move the solder over the stencil with the squeegee blade (included). That’s it. The board is now ready for pick and place operations.

| Product name | NeoDen SMT Stencil Machine |

| Dimensions | 660×470×245 (mm) |

| Platform height | 190 (mm) |

| Max PCB size | 260×360 (mm) |

| Printing speed | Labor control |

| PCB thickness | 0.5~10 (mm) |

| Repeatability | ±0.01mm |

| Positioning mode | Outside/Reference hole |

| Screen Stencil Size | 260*360mm |

| Fine adjustment range | Z-axis ±15mm X-axis ±15mm Y-axis ±15mm |

| N.W./G.W. | 11/13Kg |

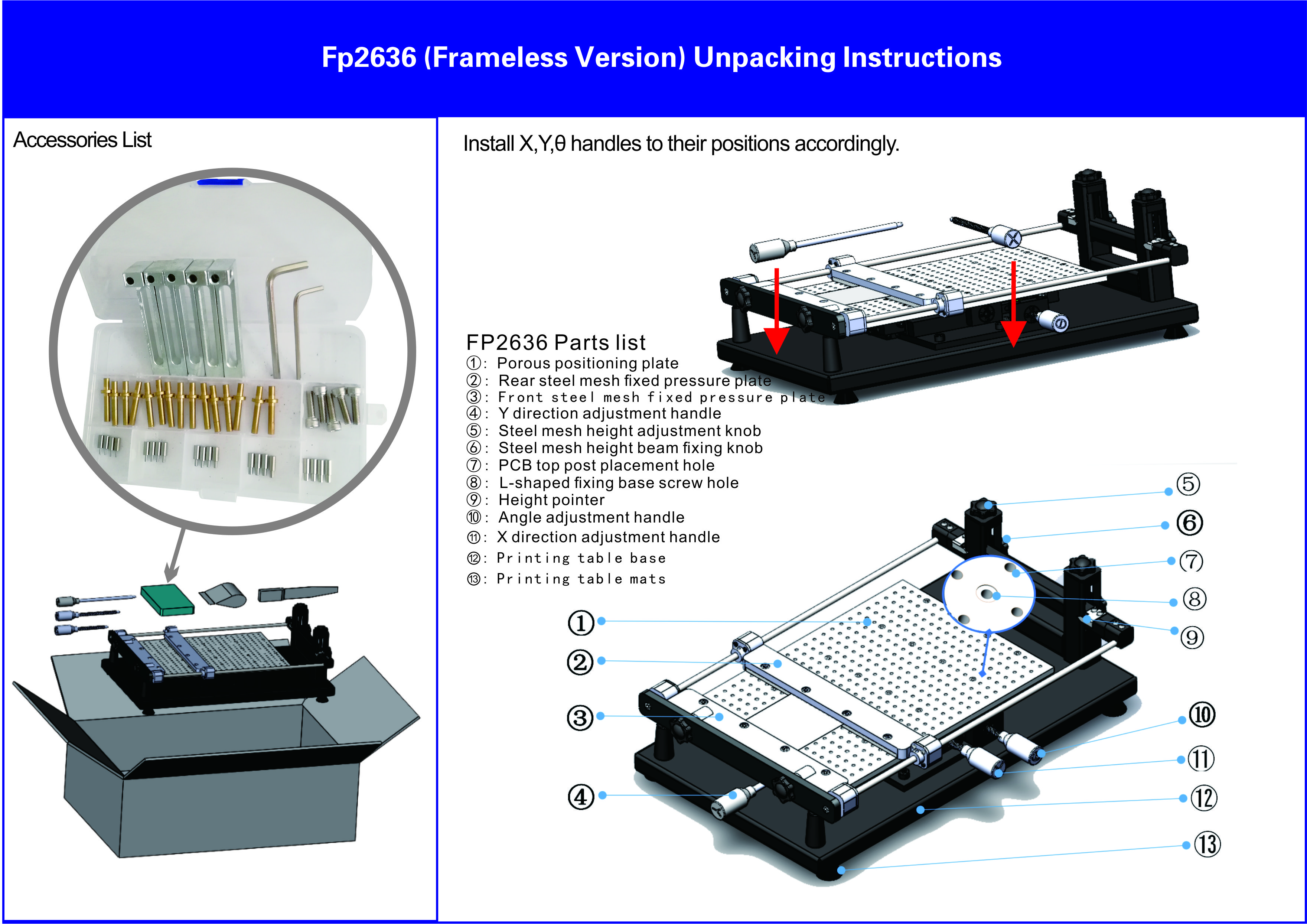

User Instructions

I. Preparation:

FP2636 stencil printer, frameless stencil, PCB, accessory box, solder paste, stirring knife, scraper blade.

II. Install the frameless stencil:

Loosen the four "Set screw", adjust the "rear stencil fixing platen" to a suitable position, loosen the 8 screws on the front and rear stencil fixing platen, and put in the "frameless stencil", tighten the screws.

III. Place the PCB:

Install four "L-shaped seats" and "positioning pins" according to the actual positioning holes on the PCB

(PS: Due to the limited XY adjustment range, the position of the "PCB" should be as close as possible to the hole location of the frameless stencil), if the PCB is easy to deform, you can install the PCB.

IV. Adjust the stencil:

Adjust the "height adjustment handle" to adjust the height of the stencil, adjust the x, y and angle adjustment handle to adjust the X/Y position.

Provide one-stop SMT assembly production line

About us

Factory

Zhejiang NeoDen Technology Co., Ltd. has been manufacturing and exporting various small pick and place machines since 2010. Taking advantage of our own rich experienced R&D, well trained production, NeoDen wins great reputation from the world wide customers.

With global presence in over 130 countries, the excellent performance, high accuracy and reliability of NeoDen PNP machines make them perfect for R&D, professional prototyping and small to medium batch production. We provide professional solution of one stop SMT equipment.

Certificate

Exhibition

FAQ

Q1: Are you trading company or manufacturer?

A: We are professional manufacturer specialized in SMT production line.

And we trade our products with our clients directly.

Q2: What’s your tem of the delivery?

A: Our ordinary delivery term is FOB Shanghai.

We also accept EXW, CFR, CIF, DDP, DDU etc. We’ll offer you the shipping charges and you can choose the one which is the most convenient and effective for you.

Q3: What’s the payment terms?

A: 100% T/T in advance.

If you need, please feel free to contact us for more information.

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.