NeoDen SMT Chip Mounter

NeoDen SMT Chip Mounter

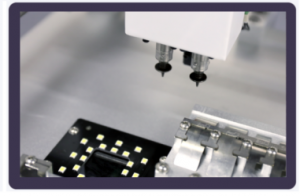

NeoDen3V

SMT Chip Mounter

2 Heads, ±180° rotation head system

Small volume, low power

High speed and accuracy

Stable performance and easy operation

Introduction

NeoDen SMT chip mounter are desktop automatic pick and place machines especially developed for research laboratories and small medium manufacturing enterprises however it will also be suitable for the serious hobbyist. These automatic pick and place machines are suitable for small batch production, laboratory research and development, product sample trials, LED SMT processing and other similar processes.

Specification

| Product Name | NeoDen SMT Chip Mounter |

||

| Machine Style | Single Gantry with 2 heads | Model | NeoDen 3V-Advanced |

| Placement Rate | 3,500CPH Vision on/5,000CPH Vision off | Placement Accuracy | +/-0.05mm |

| Feeder Capacity | Max Tape Feeder: 44pcs (All 8mm width) | Alignment | Stage Vision |

| Vibration Feeder: 5 | Component Range | Smallest Size: 0402 | |

| Tray Feeder: 10 | Biggest Size: TQFP144 | ||

| Rotation | +/-180° | Max Height: 5mm | |

| Electricity Supply | 110V/220V | Max Board Dimension | 320x390mm |

| Power | 160~200W | Machine Size | L820×W680×H410mm |

| Net Weight | 60Kg | Packing Size | L1010×W790×H580 mm |

Detail

2 Mounting Heads

Full Vision 2 heads system

±180° rotation satisfy the need of wide range components

Patented Automatic Peel-box

Feeder Capacity: 44*Tape feeder(all 8mm),

5*Vibration feeder, 10* IC Tray feeder

Flexible PCB positioning

Using PCB support bars and pins,

wherever to put the PCB, whatever the shape of PCB.

Integrated Controller

More stable performance and easier to do maintenance.

Click on the picture below to jump to the appropriate product:

Remark

Machine will start a 1-2 mins self-inspection process after boot-up. The head will travel along in X&Y axis. It will enter the operation page once finished.

After making a programming file, there may exist several programming issue, such as rotation issues of components, thus a production testing is necessary for solving issues.

Keep the machine clean, daily maintenance of the nozzles to assures its high utility.

About us

Factory

Established in 2010 with 100+ employees & 8000+ Sq.m. factory of independent property rights, to ensure the standard management and achieve the most economic effects as well as saving the cost.

3 different R&D teams with total 25+ professional R&D engineers, to ensure the better and more advanced developments and new innovation.

NeoDen supplies life-long technical support and service for all of the NeoDen machines, moreover, regular software updates based on the using experiences and actual daily request from the endusers.

Certification

Exhibition

FAQ

Q1: How long is your delivery time?

A: The general delivery time is 15-30 days after receiving your order confirmation.

Anther, if we have the goods in stock, it will only take 1-2 days.

Q2: May I know what’s the nearest airport from your company? in case I visit your company.

A: Hangzhou Airport is the nearest, welcome to visit us.

Q3: Can we visit your factory before place the order?

A: Yes, very welcome that must be nice to set up good relationship for business.

If you need, please feel free to contact us for more information!

Q1. Are you a trade company or a manufacturer?

A: We are an professional manufacturer specialized in SMT machine, pick and place machine, reflow oven, screen printer, SMT production line and other SMT equipments.

Q2. What we can do for you?

A: Total SMT machines and SMT solution, professional technical support and service.

Q3. MOQ?

A: 1 set machine, mixed order is also welcomed.